Product Description

Product Description

NCV-L855

L series machine X/Y 2 axis guide rail are both ball linear guide rail pair, sliding guide rail pair.

High rigidity construction, satisfying requirement of heavy cutting under the rapid operation of the machine tool. Coupling, bearing, spindle, ball screw, linear guide rail, tool magazine, play knife cylinder these key parts adopts Germany, Japan, ZheJiang brand precision grade accessories to ensure its accuracy and quality. Modularization of various configurations to meet customers’ different personal processing requirements: coolant through spindle (CTA); spring ring spindle; 8000rpm belt type spindle, 10000-15000rpm direct connection spindle. This series machining center is designed specially for part processing, accelerating the feed speed of the machine too, while taking into account the high rigid cutting requirements of the machine.

We also have other models : L850, L1060, L1167, L1270, L1370, L1580, L1690, L1890 which are suitable for medium and small and medium-sized metal part processing requirements.

You can choose different CNC control system with different price : Mitsubishi, ZheJiang SYNTEC, FANUC Oi-MF plus(5) or others.

Detailed Photos

Product Parameters

| Model | NCV-L855 | |||

| Travel | X axis travel | mm | 800 | |

| Y axis travel | mm | 550 | ||

| Z axis travel | mm | 550 | ||

| Distance between spindle and table | mm | 105-655 | ||

| Distance between spindle and column | mm | 600 | ||

| Table | Size | mm | 550*1000 | |

| MAX Load | kg | 500 | ||

| T slot size | 5-18*90 | |||

| Spindle | Taper | BT40 | ||

| diameter | Φ150 | |||

| speed | r/min | 8000 | ||

| Three axis | Motor power | kw | 2/2/3 | |

| Motor rate | KW | 7.5/11 | ||

| Cutting feed | m/min | 10 | ||

| Rapid feed | m/min | 36/36/20 | ||

| Arm type Tool magazine | Tool capacity | T | 24 | |

| Maximum length/ weight of tool | mm/kg | 300/8 | ||

| Maximum diameter of tool (no tool) | φ78/φ120 | |||

| Tool change time (T-T) | s | 2.5 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.571 | |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.006 | ||

| Other | Dimension | mm | 2700*2500*3150 | |

| Power capacity | KVA | 15 | ||

| Weight | kg | 6500 | ||

Packaging & Shipping

FAQ

1. MOQ

1 set

2. DELIVERY TIME

It depends on the machine and model you choose. Mostly 2 months – 4months. All machines are 100% new and not used.

3. PAYMENT TERM

T/T 30% down payment when order, 70% balance payment before shipment.

4. WARRANTY PERIOD

13 months from the date of B/L, during the warranty period, daily damage parts will be supplied freely, the after sale service will be done by dealers . After warranty period, the spare parts will be supplied at factory price.

5. Customized products

We can design and manufacture according to your specific requirements, such as change the CNC control systems, change the spindle nose taper, upgrade the standard motor and more. You do not have to hesitate to contact me.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Help Check |

|---|---|

| Warranty: | 1 Year |

| Application: | Metal |

| Process Usage: | Metal-Cutting CNC Machine Tools |

| Movement Method: | Linear Control |

| Control Method: | Closed-Loop Control |

| Customization: |

Available

| Customized Request |

|---|

How to Choose the Right Linear Rail for Your Fishing Rod

Compared to rods, linear rail is cheaper and offers a wide variety of applications. It is also corrosion resistant and has the ability to handle both tearing loads and torque forces.

A wide range of applications

Using a linear rail system is a good way to safely move things through a manufacturing process. They are used in a wide range of industries, and are especially helpful in moving items through packaging and production.

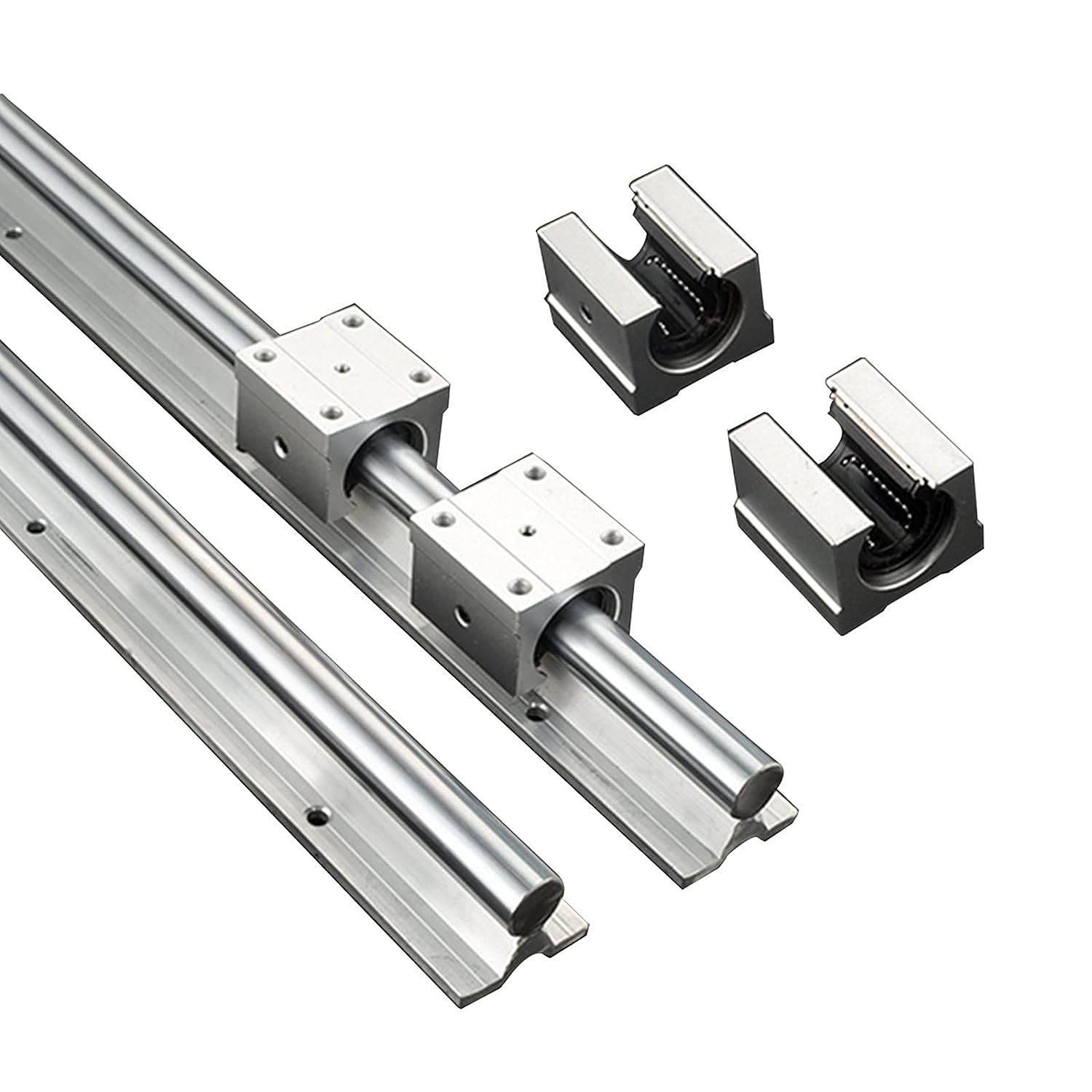

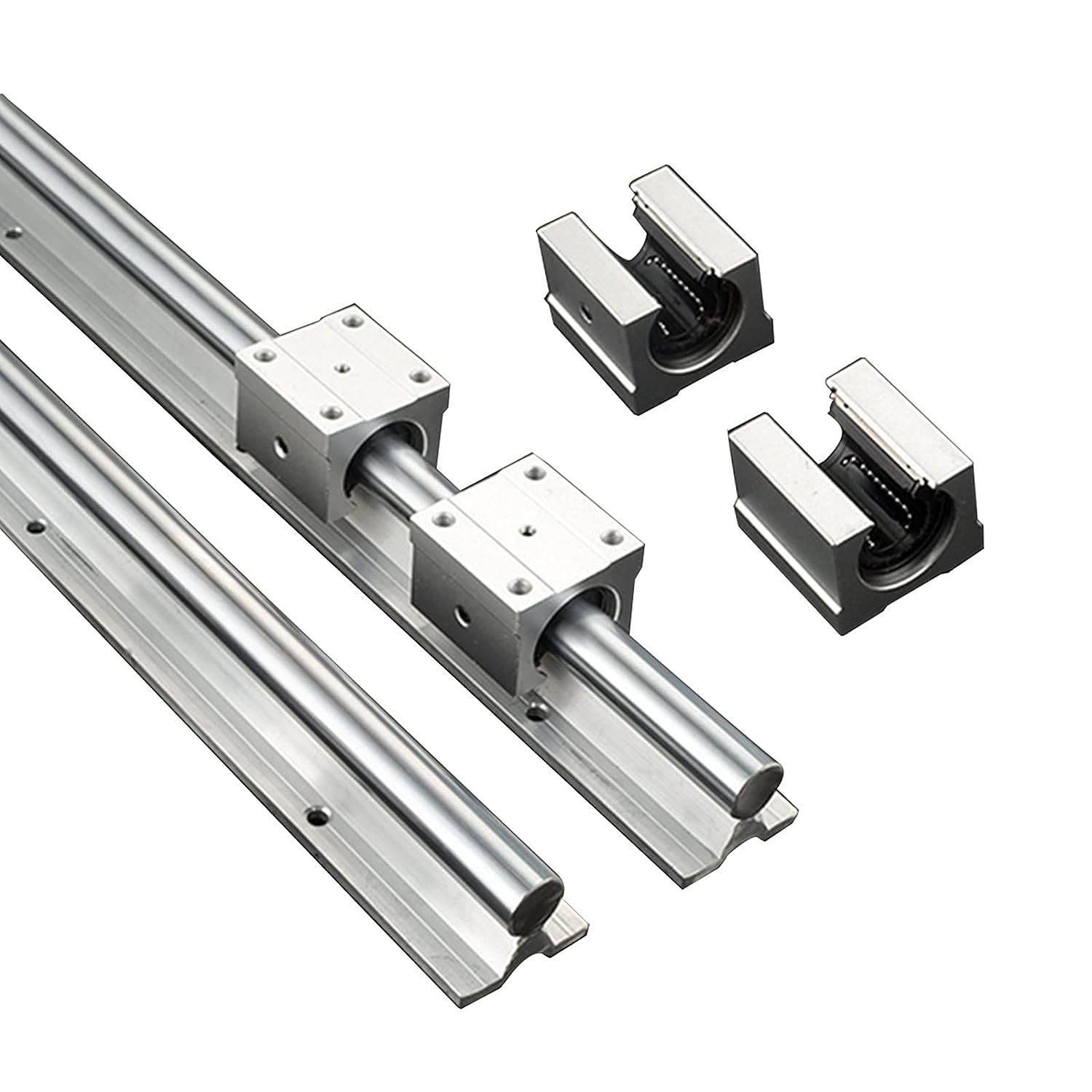

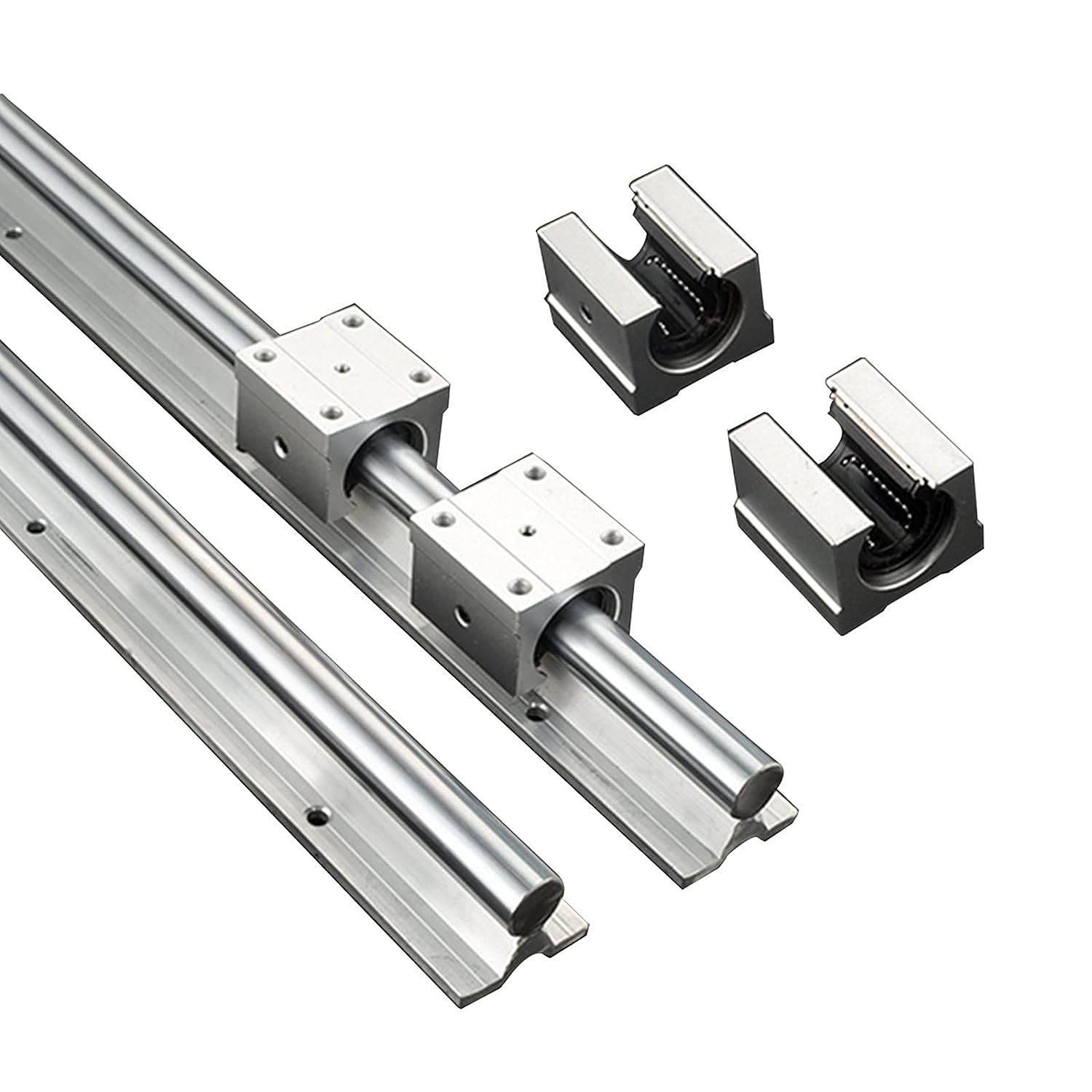

They are typically made from hardened materials such as steel, and have load-supporting balls on both sides. This helps them to handle loads from a few grams to thousands of kilograms, and can withstand overhung loads when paired with another rail.

Linear rails are also used in a variety of applications, including food and beverage production. In this industry, they are required to withstand harsh conditions and must adhere to local health and safety standards.

They are commonly used in weighing machines. They also find applications in CNC machines and moving robot arms in factory lines. The high level of rigidity and load capacity make them a good option for moving products with little friction.

Linear rails can be used vertically or horizontally. They are also a good choice for weight guidance when centered below the rail. They can join multiple rails for very long travel lengths, and can be joined to perform a seventh axis.

These rails can handle travel speeds of up to 5 m/s. They are commonly used in industrial applications, and can handle loads from a few grams to thousands. They are also useful for pneumatic and belt-driven systems, and are often used as actuator guide mechanisms.

There are many different types of linear rails. They range in size and length, and have a variety of processing methods. You can also find simple surface bearings, which are characterized by a low coefficient of friction.

For applications requiring precise positioning and precise travel accuracy, linear rail systems are the way to go. They provide the highest level of rigidity and are capable of achieving travel speeds of up to 5 m/s.

They provide large travel spaces

Various applications may call for the use of a linear rail. These can be square, rectangular or round in shape and can handle loads from a few grams to thousands of kilograms. They also have a long lifespan.

In a nutshell, a linear rail provides low friction guidance for a load. They are used in the industrial sector in a number of applications. Aside from the obvious one’s, a single linear rail can save valuable floor space. It also ostensibly has the trifecta of a runner, power screw and ball bearings.

Linear rails are not for the faint of heart. Aside from the obvious cost, you will also be expected to mount, support and install them properly. You should also consider the size, shape and quality of the components. They can be bought in any length, from a few inches to several feet. They are also made from a wide variety of materials. Some of the materials used include steel, aluminum, and polymers. They can be shaped and joined to achieve very long travel lengths. They are also susceptible to damage.

The name of the game is to choose a good set of quality linear guides. There are two types in common usage today. The first is a runner with ball bearings, and the second is a runner with rollers. The latter is the less expensive choice. Aside from the usual suspects, you can also choose a saddle or fixed slide. It’s a good idea to use them in pairs. They are also the best suited for heavy duty applications.

The most important factor to consider when selecting a linear rail is the load capacity. While a single linear rail can be used in many applications, multiple rails are the best option for the job.

They withstand both tearing loads and torque forces

Generally constructed from corrosion resistant steel, linear rails are sturdy and robust enough to handle a wide variety of applications. They are usually used on mechanical systems with high precision requirements. They also provide a smooth and accurate motion.

In order to achieve the highest level of efficiency, the rail must be accurately supported and installed. It may also require some form of lubrication. The design of the rail may be influenced by factors like size, shape, and frequency of use.

For instance, linear rails are often used for actuator guides. These guide mechanisms provide a smooth, reliable, and low-friction motion. A runner is inserted inside the rail and moves from front to back. The runner may have ball bearings or a pair of sleeve bearings.

Another notable feature of the linear rail is the ability to withstand torque and tearing forces. They are also capable of handling larger loads, providing greater stability to the entire system. The most important feature is the fact that they are easy to install and remove. They are also capable of achieving high speeds.

There are many types of linear rails to choose from. Some may be suitable for consumer applications, while others are more suited for industrial applications. Some of the common factors that affect the lifespan of a rail include size, frequency of use, and mounting. A single rail is a space saver, while dual rails maximize bearing life.

Some of the major components in a linear slide include the runner, the bearings, and the carriage. In addition to the runner, the slide may also feature the motor, power screw, or other components. Some of these features are the smallest relative to the overall linear slide.

They’re cheaper than rods

Choosing the best linear rails for your fishing rod is no small feat. You must understand the characteristics of various rails before you can find the one that best fits your needs. You may also want to consider choosing a rail that will last for many years. This is especially true if you are fishing in saltwater.

The best linear rails are designed with a variety of factors in mind. They will help you achieve precision and longevity. In addition, these guides are made of materials that are durable. They are also affordable. There are a variety of choices, including round and square rails.

The best rods have a good selection of features, including a good reel seat and flexible nickel/titanium snake guides. You should also look for a rod that has a smooth but firm handle and a rod that is easy to use. The best rods will also be a bit pricier, but you will not regret your investment.

The best rods use quality cork and stacks of smaller cork rings. The best rods have a cork handle that has a good feel. This handle has a big flare at the bottom and has narrow cork rings on the top. This handle is the best fly rod handle that you will find.

The best rods also have a well made reel seat that will hold firmly and easily. It should also have thin nylon spacers between the rings for a positive lock up. The reel seat should also be made from an anodized black aluminum up-lock seat with a synthetic gray insert.

The best rods also have reputable guide sets. This includes a new CERECOIL stripping guide made of nickel Titanium. This guide uses a multi-taper design that removes material from the weakest areas, thus improving dampening and recovery.

They’re corrosion-resistant

Stainless steel linear rails are essential in many industries, including vacuum applications, the pharmaceutical industry, and electronic circuit machines. They are also necessary for washing down cycles.

Stainless steel rails have excellent corrosion resistance. The steel surface is coated with an inert layer that prevents the rusting of the steel. Steel surfaces can rust over time, though, and rust can contaminate equipment. It’s important to check with your manufacturer about any corrosion resistance treatments that may be available.

Carbon steel linear bearings can be treated with hard chrome, black chrome, or a corrosion-resistant coating. These bearings are more expensive than those made of austenitic steel, but they provide similar corrosion resistance. They also have a lower hardness.

Silicon Nitride balls are another option. These balls are 40% lighter than steel, so they can carry higher loads without causing electrolysis. They’re also inert to chemicals and are capable of higher speeds. They’re available in closed or open designs. They come in four different sizes. They’re also coated with CZPT coating, which reduces the surface area of the balls in contact with the steel.

Another option is electroless nickel plating, which is inexpensive. This type of plating uses nickel instead of copper to prevent corrosion. It also offers a low friction coefficient.

Another option is drylin(r) linear technology, which combines the corrosion-resistance of thermoplastic bearing liners with shafting. This technology is ideal for chemical washdown environments, as well as those in saltwater environments. These systems also provide excellent rigidity and high load-bearing capacities.

Other types of linear guides are also available. Plain bearing guides may be appropriate for less expensive applications, while round shaft systems may be better for more expensive applications.

editor by Dream 2024-05-15

China manufacturer Stainless Steel Miniature Linear Guide Mgn3 Mgn5 Mgn7 Mgn9 Linear Guide Rails and Block for Automatic Machine

Product Description

Product Description

| Product Name | Stainless Steel Miniature Linear Xihu (West Lake) Dis. MGN3 MGN5 MGN7 MGN9 linear guide rails and block for Automatic Machine |

| Material | Gcr15 bearing steel or stainless steel |

| Size | 7/9/12/15mm |

| Length of linear guide rail | 100mm-4000mm,any length will be available |

| Usage | CNC machinery |

Product Parameters

Packaging & Shipping

Packaging Details: 1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Delivery Detail: within 5-15 days against payment

Company Profile

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is located at Xihu (West Lake) Dis. Industrial Zone Xihu (West Lake) Dis. County which is the beautiful Xihu (West Lake) Dis. Water City and the famous painting and calligraphy village.The south is 308 National Road, the west is the 105 National Highway, the north is HangZhou-HangZhou Highway, the position is very superior. It is 1 of the biggest linear guide manufacturers in China.

Our Services

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters, production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons. We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products, and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products, it is really too hard to send all of catalogue and price list for you. Please inform us the style you interested, we can offer the pricelist for your reference.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | 3D Printer |

|---|---|

| Material: | Stainless Steel |

| Structure: | Linear Guide Rail and Block |

| Samples: |

US$ 9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the various mounting options and installations for linear rails in different settings?

Linear rails can be mounted in various configurations to suit different settings and applications. The choice of mounting options depends on factors such as space constraints, load requirements, and the desired motion characteristics. Here are some common mounting options and installations:

1. Horizontal Mounting: Linear rails are horizontally mounted when the desired linear motion is along the horizontal axis. This configuration is commonly used in applications such as CNC machines, where the tool needs to move horizontally across the workpiece.

2. Vertical Mounting: Vertical mounting involves installing linear rails to support vertical linear motion. This configuration is prevalent in applications like vertical machining centers, where the spindle moves vertically to perform machining operations on the workpiece.

3. Inverted Mounting: Inverted mounting is where the linear rail is installed upside down. This configuration is suitable when space limitations or specific design requirements dictate the need for the rail to be positioned below the moving component. Inverted mounting is common in some types of robotic systems.

4. Parallel Mounting: Linear rails can be mounted in parallel to support multiple carriages or moving components. This configuration is beneficial in applications where synchronized linear motion is required, such as in certain types of material handling systems or conveyor belts.

5. Cantilever Mounting: Cantilever mounting involves mounting the linear rail with one end extending beyond a support structure. This configuration is used when access to one side of the linear motion is required, such as in loading and unloading stations on manufacturing lines.

6. Tandem Mounting: Tandem mounting involves mounting multiple linear rails in tandem to share the load and provide additional support. This configuration is suitable for applications with heavy loads or long travel distances, ensuring stability and preventing deflection.

7. Floating Mounting: Floating mounting allows for some degree of flexibility in the alignment of the linear rail. This is useful in applications where there may be minor misalignments or variations in the mounting surface.

The choice of mounting option depends on the specific requirements of the application, and engineers must carefully consider factors such as load distribution, accessibility, and alignment to ensure optimal performance and longevity of the linear rail system.

What are the typical load capacities and travel distances for linear rails?

The load capacities and travel distances for linear rails vary based on the specific design, size, and application requirements. Here are general considerations:

Load Capacities:

- Light-Duty Applications: Linear rails in smaller sizes may be suitable for light-duty applications with load capacities ranging from a few hundred pounds to a few thousand pounds. These are commonly used in applications like 3D printers and light-duty automation systems.

- Medium-Duty Applications: Linear rails in medium sizes are designed for applications with moderate load requirements. Typical load capacities for medium-duty linear rails range from a few thousand pounds to tens of thousands of pounds. These are often used in CNC machines, robotic systems, and material handling equipment.

- Heavy-Duty Applications: Larger linear rails are built for heavy-duty applications with substantial load requirements. Load capacities for heavy-duty linear rails can extend into the hundreds of thousands of pounds. These are employed in industrial machinery, aerospace testing equipment, and other heavy-duty applications.

Travel Distances:

- Short-Range Travel: Some linear rails are designed for short-range travel, with typical distances ranging from a few inches to a few feet. These are suitable for applications with limited linear motion requirements, such as in certain types of printing machinery.

- Medium-Range Travel: Linear rails for medium-range travel cover distances from a few feet to several feet. These are commonly used in applications like CNC machines and automation systems where moderate linear motion is required.

- Long-Range Travel: Linear rails with long-range travel capabilities are designed for applications where extensive linear motion is necessary. These can cover distances ranging from several feet to meters and are used in applications such as large-scale industrial automation and material handling systems.

It’s essential to consult manufacturer specifications and consider factors such as speed, acceleration, and environmental conditions when selecting linear rails to ensure they meet the specific load and travel requirements of a given application.

What are linear rails, and how are they used in linear motion systems?

Linear rails, also known as linear guides or linear slides, are mechanical components used in linear motion systems to facilitate smooth and precise movement along a straight path. They typically consist of a rail and a carriage. The rail is a long, rigid structure with a specially designed profile, while the carriage is mounted on the rail and holds the load to be moved.

Linear rails are widely used in various applications, including manufacturing machinery, robotics, 3D printers, and automated systems. They provide guidance and support to the moving components, minimizing friction and ensuring accurate and repeatable motion. The design of linear rails allows for high load-carrying capacity and can accommodate different types of loads, such as radial or axial loads.

Linear motion systems incorporating linear rails offer advantages such as improved precision, reduced wear and tear, and increased efficiency in comparison to traditional sliding mechanisms. The choice of linear rails depends on factors such as load capacity, speed, accuracy requirements, and environmental conditions in the specific application.

editor by Dream 2024-05-15

China OEM Horizontal Mini Metal Linear Lathe High Precision H36/H46 Lathe Machine linear rail bearing grease

Product Description

Horizontal Mini Metal Linear Xihu (West Lake) Dis.way CNC Lathe H36/H46 High Precision Lathe Machine

Product Description

Standard configuration:

Independent spindle

Linear rail ZheJiang

Collet Chuck

Gang type tool post

Product Parameters

SPECIFICATIONS

| SPECIFICATIONS | Units | H36 | H46 |

| Swing over bed | mm | 360 | 460 |

| Swing over cross slide | mm | 110 | 140 |

| Distance between centers | mm | 250 | 330 |

| Spindle bore | mm | 48 | 56 |

| Spindle nose type | – | A2-5 | A2-5 |

| Spindle speed steps | – | Stepless | Stepless |

| Spindle speed range | rpm | 2500(Optional:4000) | 3500 |

| Turret/tool post | – | Gang type | Gang type |

| Tool size | mm | 20 x 20 | 25 x 25 |

| X axis travel | mm | 340 | 360 |

| Z axis travel | mm | 250 | 330 |

| X axis rapid traverse | mm/min | 15000 | 15000 |

| Z axis rapid traverse | mm/min | 15000 | 15000 |

| Main spindle motor | kw | 4 | 5.5 |

| Xihu (West Lake) Dis. rail type | – | Linear rail | Linear rail |

| Machine weight | kg | 1500 | 2200 |

| Overall dimension | mm | 2000x1400x1580 | 2300x1800x1600 |

Detailed Photos

Company Profile

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What’s your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in HangZhou City ,ZheJiang Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What’s the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

5: What’s the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online after-sales service |

|---|---|

| Warranty: | 13months |

| Type: | Horizontal Lathe |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Choosing the Right Type of Linear Rail for Your 3D Printer

Using a linear rail in your 3D printer is a common way to provide support for the bed, but there are some drawbacks to using this type of rail. Learn about the different types of rail and how to select the best one for your project.

Square rail

Choosing the right linear rail can bring significant advantages in cost, durability and performance. Choosing the right rail type is a key step before deciding on the overall design. Choosing the correct type will depend on your application’s requirements. The selection process involves learning from past mistakes and defining the system’s objectives. Choosing the right rail isn’t unlike choosing other components for a machine.

Unlike round rail, square rails require a flat mounting surface. Moreover, square rails can’t span gaps. The rails must be aligned perfectly to achieve the desired parallelism. Square rails also need to be lubricated properly.

Square rails are used for applications that require high load capacity. Square rails are typically used for machine tool applications. They have a greater load capacity than round rails. They can handle heavy loads and moment loads. They provide high precision and accuracy. They also have more surface contact than round rails.

Generally, square rails are more expensive than round rails. Square rails are also more prone to debris. They also need tighter parallelism than round rails. Square rails also need a straight continuous support.

Square rails have higher load capacity and precision. However, they have higher maintenance costs. Square rails also need to be installed carefully. They can be prone to misapplication. Misapplication can happen due to miscalculation or personal bias. Choosing the right rail type isn’t always the right solution for your application. It’s always best to start with preliminary calculations before deciding.

Round rails are generally faster to install. They also allow for greater ranges in rail height. They can also handle imperfect parallelism. However, they also have lower load capacity. They require more parts than square rails.

They can be installed vertically or horizontally. They are also available in different sizes. CZPT provides bearing blocks in different seals. Their bearing blocks can be purchased in long, normal or short block versions. CZPT’s long block versions have a self-lubricating option.

Round rails are more forgiving than square rails. They have less tendency to pull up. They are also less prone to deflection.

CZPT(r) T

Whether you are working in the manufacturing, automotive, pharmaceutical, or food industry, CZPT (r) T linear rail assemblies can be configured for your application. These rail assemblies are manufactured from lightweight aluminum and can be customized to your specifications. They are designed to replace recirculating ball bearings, eliminating messy oil, grease, and downtime. You can download CZPT (r) T linear rail assemblies as CAD files to facilitate customization.

There are two main types of CZPT (r) T linear rails. The T-shaped design is manufactured from hard-anodized aluminum. These linear guides are designed to be lightweight, easy to install, and durable. They are perfect for applications where speed is critical.

For more than 50 years, Sealstrip has been manufacturing packaging solutions with its patented package reclosure device. In its heyday, metal bearings were the standard for package reclosure, but they proved to be expensive and often required frequent maintenance. Fortunately, CZPT (r) T linear guide systems are a better option. They are oil free, corrosion resistant, and come with a number of functional and design features that rival metal bearings.

CZPT (r) T linear rails are easy to install and maintain, so you can focus on the task at hand. Their design is efficient, allowing for the smoothest, most precise motion. CZPT (r) T rail assemblies are also available in stainless steel, making them ideal for applications in harsh environments. These bearings have a unique split adapter that makes installation easy. They are compatible with standard ball bearings. They can carry heavy loads up to 800 pounds.

In addition to CZPT (r) T linear rails, CZPT (r) family of products includes CZPT (r) R linear plain bearings, CZPT (r) S anodized aluminum shafting, and CZPT (r) slide tables. All CZPT (r) products are designed to meet your motion control component needs. They are available from 28,000 stock items. You can also order energy chain systems and chainflex continuous flex cables. These linear guides are designed to help you get the most from your manufacturing equipment. They are the ideal way to replace recirculating ball bearings.

liding contact guides

Generally, linear guides are composed of guide rails, slide bodies and bearing inserts. These systems are widely used in different applications. They are designed to reduce friction, increase power efficiency and increase overall efficiency of units. The guide can be made of steel or aluminum. The slide can be plain surface bearing or a rolling-element bearing. These types of slides have a low frictional resistance, and can be used in high speed applications.

Sliding contact guides on linear rails have sliding contact along the entire length of the rail. The sliding contact is made by a rolling-element bearing, such as a ball, roller or cam roller. Linear bearing slides can be lubricated with grease, oil or vacuum lubricant. The use of linear bearing slides helps to minimize operating temperatures and improves overall efficiency of units.

These guides are used in applications with high precision. They are a good option in applications with limited space requirements. They also provide increased load capacity while reducing the size of the unit.

The present invention provides an alternative to the prior art linear guides. It consists of a linear guide with a replaceable bearing element. This element is removable from the slider without replacing the slide body. It also eliminates the need to replace roller elements in the bearing mechanism.

The sliding contact guides on linear rails are ideal for applications with high accuracy. They are especially useful in high speed applications. They can help grippers pick up objects more accurately. They can also be used for industrial sliding doors. They are also used in a variety of robotics applications.

The sliding contact guides on linear rails can be used in a wide range of applications, from precision machinery to computer numerical control machines. They are available in different sizes and configurations, including the MINISCALE PLUS series. They can be used in vacuum conditions of up to 10-7 mbar. They are ideal for applications requiring high accuracy and reduced power consumption.

They are available in a wide range of sizes, including 7 mm to 15 mm wide. They also have travel distances of up to 42 mm. The dynamic load capacity ranges from 207 to 1109 N. They also offer accelerations of up to 50 m/s.

Drawbacks of “traditional” linear rail in a 3D printer build

Using linear rails in a 3D printer build can increase print quality, but there are also drawbacks. There are some advantages to using linear rails, but you’ll also need to consider the cost and complexity of using them.

A traditional linear rail is a rectangular piece of steel with two dovetails along each side. It’s used to mount the carriage to the printer, and it is designed to provide smoother motion than a linear rod. Despite this, a rail can also be curved, which can create problems when printing.

Another disadvantage is that a single linear rail is more expensive than two linear rods, and it requires a physical frame for mounting. However, it can save you the cost of buying two rods and can also create a unique aesthetic for your 3D printer. Another advantage is that you can anchor the rail for greater rigidity and load-bearing capacity. You’ll also need to make sure that your rails are properly lubricated for a long life. If they aren’t, you’ll likely experience problems with print quality.

The drawbacks of using a linear rail in a 3D printer build aren’t that serious, but they’re still something to consider. If you have the budget, you may want to invest in a more capable printer, rather than in a linear rail. Also, remember that the stiffer your rails are, the less backlash you’ll experience. You’ll also avoid ringing artifacts, which will make your prints look less smooth. Regardless of the type of rail you use, it’s important to make sure that you mount it correctly.

editor by Dream 2024-05-14

China wholesaler Linear Type 12000bph Bottled Beverage Water Labeling Machine for OPP Label Hot Glue linear rail carriage

Product Description

Product description

linear OPP label sticking machine

- Name: hot glue opp label sticking machine

Label sticking method: round label sticking

Usage glue type: hot glue

1.1).label cutting knife adjust easy

1.2).vacuum absorb wheel adopt to high hardness material making, add shrink treatment programme to cut label abrasion, avoid statics produce.

1.3).exchange compatible workin can do at 10minute quickly finish.

1.4). Can use manual manipulation precision and convenient to adjust knife plate site.

1.5). Vacuum absorb wheel and label cutting part adopt to abrasion heat special matrial making.

1.6).when change label length, auto adjust button can auto adjust I-MARK position

2. Usage label

label material:OPP(gear type)

label specification: as client requirement

label sticking method: linear type hot glue sticking label

3. Facility description

3.1) adopt to wheel stick label method

3.2) via label roll transport label via label wheel supply,as guid rail to do label sticking operation.

3.3) label via label supply wheel, transit auto test I-MARK

3.4) once sure electrici eye position, modem auto adjust wheel supply operation speed, can no mistake cutting label position.

3.5) label via label supply gear, into cutting part to do cutting operation, then cutting label transport to vacuum absorb plate

3.6) via conveyor belt transport container to wheel gear to do arrange, after glue spray label, to do guid first time label sticking, then rely on in-phase operation to do perfect label sticking operation.

- Device descripton:

4.1) controlling: operation controling,frequency convertor

4.2) safe device

drive part set overload operation protection device

supply wheel gear abnormal statics stop device

no bottle supply inspection device

bottle supply overload inspection device

- Main fracture

5.1)conveyor

5.2) supply star wheel

5.3) label station

5.4) vacuum absorb plate

5.5) drive part

5.6)hot glue glue supply machine

5.7)glue roller wheel

5.8)in phase belt

5.9) label cutting part

5.10) label guid rectify

5.11)machine frame

5.12) vacuum system and air source treatment

5.13) controlling system

6. Compatible part

6.1) wheel gear and guard board

6.2) cavcuum absorb plate

6.3)screw pusher

6.4) rub bottle guard board

Facility main parameter

| Facility name | Automatic linear hot glue opp label sticking machine |

| Machine model | JL-04B-4P |

| Main motor power | 2.2KW |

| Main motor brand | ZheJiang brand |

| controller | Schneide |

| Servo motor | Schneide 1.5KW |

| PLC module | Schneide |

| transit | SICK Schneide Panasonic |

| programmer | SICK |

| Low pressure electricity | Schneide |

| Voltage | 380V±10% |

| Frequency convertor | 50HZ |

| Whole machine power | About 8KW |

| Label type | Single round body label |

| Applied bottle type | Round bottle ∮40-105mm,height=80-350MM |

| Label size | Length 125-325mm,height 20-150mm |

| Label spray method | Roller coating(label head and end end about each 10mm) |

| Label usage method | Roll label |

| Capacity | 8000b/h (common 500ml bottle type) |

| Compressor air pressure | MIN5.0bar MAX8.0bar |

| Compressor air consumption quantity | 0.2M³/minute |

| Whole machine weight | About 2000kg |

| Machine overall size | L=3150 W=1570 H=1800 |

OPP label sticking machine-rotary type

Rotary type opp hot melt label sticking machine

Process: Infeed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish

Technical Parameters:

| Name | opp Hot Melt Labeling Machine |

| Power supply | Three-phase 380V 60 Hz 5000W |

| Machine dimensions: | 3650mm×1700mmX 2571mm(can be adjusted by customer requirements) |

| Method of speed adjustment: | uninterrupted – adjust rate |

| Labeling precision: | ±1mm |

| Labeling speed | 10000-12000bph |

| Maximum label width: | 200mm(standard width, can be adjusted ) |

| The maximum outer diameter of label | 600mm |

| Paper core Hot melt | 152 mm |

| Labeling glue: | glue at both ends of each label with hot melt |

| Gluing temperature: | 120~160ºC |

| Labeling type for products: | suitable for round or square containers made of plastic, metal, glass |

| Type of label: | bopp ,paper-plastic composite film ,paper label |

| Labeling stations: | 12per cycle |

| Machine weight: | about 3000 kg |

Method of Operation

The containers are picked up by the infeed starwheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells.

The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point.

Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. The label with the glue strip on its leading edge is transferred to the container. This glue strip ensures an exact label positioning and a positive bond. As the container is rotated during label transfer, labels are applied tightly. Gluing of the trailing edge ensures proper bonding.

Equipment constitutes

Mainframe

CZPT servo system

CZPT servo drive system

CZPT motion controller

Germany Schneide Touch-screen

Japan SUNX Digital Color Mark Sensor

Japan SUNX Detection Sensor for coating adhesive

Japan SUNX Photoelectric Sensor

Japan SUNX Photoelectric Sensor

Mechanical Parts

| Transportation institution | TRANSTECNO motor 750W(with deceleration by TRANSTECNO ), inverter speed control |

| Conveyor | Italy FLEXON LF820-K325 industrial nylon chain plate conveyor |

| Mainframe transportation institution | TRANSTECNO motor 2.2Kw (with deceleration by TRANSTECNO) |

| Sub bottle institution | industrial worm sub bottle institution |

| Into bottle institution | with worm sub bottle institution and starwheel position feeding institution to ensure the accuracy and stability of loading |

| Position institution | Mechanical pre-location , using the camwheel institution to planish the bottle for label positioning |

| Labeling institution | Containers are pick up by rotary wheel ,labeling during the rotation. |

| Supply label institution | high speed servo opp label supply system (drive by servo-motor) |

| Pressing label institution | Arc brush unit |

| Xihu (West Lake) Dis.d bottle institution | adjust by double coordinate section guide rail |

| Glue supply system | hot melt glue supply system(German SEIMEC control system) ensures the accuracy and uniformity of gluing |

Safety part of the machine

| Safety protection | In order to keep the operator safety ,when the machine is running please close the protective doors |

| Lack of label alarm | Set an alarm to remind the operator to change the label when the label will be use out |

| Lack of bottle alarm | When lack of the bottle the machine will stop and make an alarm .The machine will restart automatically as soon as the bottles have been put that will facilitate on-line production |

| Leak of labeling alarm | To control the quality of labeling |

| Pressure testing | When the pressure can not meet the equipment requirement ,the machine will stop to against bad products produce |

| Vacuum testing | When the vacuum can not meet the equipment requirement ,the machine will stop to against bad products produce |

| Temperature testing | When the temperature can not meet the equipment requirement , the machine will stop to against bad products produce |

Suit product photos:

After sale service

1.. Engineer install and train client how to use and maintain machine

2. 1 year guarantee

Some basic details need buyer support:

1. bottle and label samples

2. capacity requirement, we will match solution as it. we have capacity from 5000bph to 18000bph

We also supply Raw material required for filling line required:

preform&cap &label&PE film

6. Detailed photos

Main Spare Parts List:

| No. | ITEM | BRANDS | ORIGIN | QTY |

| 1 | Sevor motor for sending label | Sanyo | Janpan | 1 |

| 2 | Sevor driving motor for sending label | Sanyo | Janpan | 1 |

| 3 | Frequency | Danf | Denmark | 3 |

| 4 | Air switch | Xihu (West Lake) Dis. | Franch | 1 |

| 5 | Circuit Breaker | TE | Franch | 1 |

| 6 | Relay | Omron | Janpan | 3 |

| 7 | Emergency Switch (Front and back) | TE | Franch | 2 |

| 8 | Switch Power | Ming wei | China ZheJiang | 1 |

| 9 | Control cable | China | ||

| 10 | PLC | Siemens | Germany | 3 |

| 11 | Touch Screen (7inch) | Schneide | Germany | 1 |

| 12 | Warning light | Q-Light | Korea | 1 |

| 13 | Detection photoelectric switch | Sick | Germany | |

| 14 | Electric eye detection of color label | Sunx | Germany | 1 |

| 15 | Main motor 2200W | ABB | America | 1 |

| 16 | Main motor speed reducer | ABB | America | 1 |

| 17 | Conveyor motor 750W | ABB | America | 1 |

| 18 | Speed reducer for conveyor | ABB | America | 1 |

| 19 | Carbinet of glue motor | ABB | America | 1 |

| 20 | Ajustable motor for labeling 60w | Siemens | German | 1 |

| 21 | Stainless Steel 304 | China | ||

| 22 | Conveyor | China |

Our workshop

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | for Year Service |

|---|---|

| Warranty: | One Year |

| Automatic Grade: | Automatic |

| Applicable Industry: | Beverage, Beer, Costmetic Bottle… |

| Application: | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Rice, Flour, Seasoning, Dairy Products |

| Type: | Hot Melt Adhesive Labeling Machine |

| Customization: |

Available

| Customized Request |

|---|

How to Choose the Right Linear Rail for Your Fishing Rod

Compared to rods, linear rail is cheaper and offers a wide variety of applications. It is also corrosion resistant and has the ability to handle both tearing loads and torque forces.

A wide range of applications

Using a linear rail system is a good way to safely move things through a manufacturing process. They are used in a wide range of industries, and are especially helpful in moving items through packaging and production.

They are typically made from hardened materials such as steel, and have load-supporting balls on both sides. This helps them to handle loads from a few grams to thousands of kilograms, and can withstand overhung loads when paired with another rail.

Linear rails are also used in a variety of applications, including food and beverage production. In this industry, they are required to withstand harsh conditions and must adhere to local health and safety standards.

They are commonly used in weighing machines. They also find applications in CNC machines and moving robot arms in factory lines. The high level of rigidity and load capacity make them a good option for moving products with little friction.

Linear rails can be used vertically or horizontally. They are also a good choice for weight guidance when centered below the rail. They can join multiple rails for very long travel lengths, and can be joined to perform a seventh axis.

These rails can handle travel speeds of up to 5 m/s. They are commonly used in industrial applications, and can handle loads from a few grams to thousands. They are also useful for pneumatic and belt-driven systems, and are often used as actuator guide mechanisms.

There are many different types of linear rails. They range in size and length, and have a variety of processing methods. You can also find simple surface bearings, which are characterized by a low coefficient of friction.

For applications requiring precise positioning and precise travel accuracy, linear rail systems are the way to go. They provide the highest level of rigidity and are capable of achieving travel speeds of up to 5 m/s.

They provide large travel spaces

Various applications may call for the use of a linear rail. These can be square, rectangular or round in shape and can handle loads from a few grams to thousands of kilograms. They also have a long lifespan.

In a nutshell, a linear rail provides low friction guidance for a load. They are used in the industrial sector in a number of applications. Aside from the obvious one’s, a single linear rail can save valuable floor space. It also ostensibly has the trifecta of a runner, power screw and ball bearings.

Linear rails are not for the faint of heart. Aside from the obvious cost, you will also be expected to mount, support and install them properly. You should also consider the size, shape and quality of the components. They can be bought in any length, from a few inches to several feet. They are also made from a wide variety of materials. Some of the materials used include steel, aluminum, and polymers. They can be shaped and joined to achieve very long travel lengths. They are also susceptible to damage.

The name of the game is to choose a good set of quality linear guides. There are two types in common usage today. The first is a runner with ball bearings, and the second is a runner with rollers. The latter is the less expensive choice. Aside from the usual suspects, you can also choose a saddle or fixed slide. It’s a good idea to use them in pairs. They are also the best suited for heavy duty applications.

The most important factor to consider when selecting a linear rail is the load capacity. While a single linear rail can be used in many applications, multiple rails are the best option for the job.

They withstand both tearing loads and torque forces

Generally constructed from corrosion resistant steel, linear rails are sturdy and robust enough to handle a wide variety of applications. They are usually used on mechanical systems with high precision requirements. They also provide a smooth and accurate motion.

In order to achieve the highest level of efficiency, the rail must be accurately supported and installed. It may also require some form of lubrication. The design of the rail may be influenced by factors like size, shape, and frequency of use.

For instance, linear rails are often used for actuator guides. These guide mechanisms provide a smooth, reliable, and low-friction motion. A runner is inserted inside the rail and moves from front to back. The runner may have ball bearings or a pair of sleeve bearings.

Another notable feature of the linear rail is the ability to withstand torque and tearing forces. They are also capable of handling larger loads, providing greater stability to the entire system. The most important feature is the fact that they are easy to install and remove. They are also capable of achieving high speeds.

There are many types of linear rails to choose from. Some may be suitable for consumer applications, while others are more suited for industrial applications. Some of the common factors that affect the lifespan of a rail include size, frequency of use, and mounting. A single rail is a space saver, while dual rails maximize bearing life.

Some of the major components in a linear slide include the runner, the bearings, and the carriage. In addition to the runner, the slide may also feature the motor, power screw, or other components. Some of these features are the smallest relative to the overall linear slide.

They’re cheaper than rods

Choosing the best linear rails for your fishing rod is no small feat. You must understand the characteristics of various rails before you can find the one that best fits your needs. You may also want to consider choosing a rail that will last for many years. This is especially true if you are fishing in saltwater.

The best linear rails are designed with a variety of factors in mind. They will help you achieve precision and longevity. In addition, these guides are made of materials that are durable. They are also affordable. There are a variety of choices, including round and square rails.

The best rods have a good selection of features, including a good reel seat and flexible nickel/titanium snake guides. You should also look for a rod that has a smooth but firm handle and a rod that is easy to use. The best rods will also be a bit pricier, but you will not regret your investment.

The best rods use quality cork and stacks of smaller cork rings. The best rods have a cork handle that has a good feel. This handle has a big flare at the bottom and has narrow cork rings on the top. This handle is the best fly rod handle that you will find.

The best rods also have a well made reel seat that will hold firmly and easily. It should also have thin nylon spacers between the rings for a positive lock up. The reel seat should also be made from an anodized black aluminum up-lock seat with a synthetic gray insert.

The best rods also have reputable guide sets. This includes a new CERECOIL stripping guide made of nickel Titanium. This guide uses a multi-taper design that removes material from the weakest areas, thus improving dampening and recovery.

They’re corrosion-resistant

Stainless steel linear rails are essential in many industries, including vacuum applications, the pharmaceutical industry, and electronic circuit machines. They are also necessary for washing down cycles.

Stainless steel rails have excellent corrosion resistance. The steel surface is coated with an inert layer that prevents the rusting of the steel. Steel surfaces can rust over time, though, and rust can contaminate equipment. It’s important to check with your manufacturer about any corrosion resistance treatments that may be available.

Carbon steel linear bearings can be treated with hard chrome, black chrome, or a corrosion-resistant coating. These bearings are more expensive than those made of austenitic steel, but they provide similar corrosion resistance. They also have a lower hardness.

Silicon Nitride balls are another option. These balls are 40% lighter than steel, so they can carry higher loads without causing electrolysis. They’re also inert to chemicals and are capable of higher speeds. They’re available in closed or open designs. They come in four different sizes. They’re also coated with CZPT coating, which reduces the surface area of the balls in contact with the steel.

Another option is electroless nickel plating, which is inexpensive. This type of plating uses nickel instead of copper to prevent corrosion. It also offers a low friction coefficient.

Another option is drylin(r) linear technology, which combines the corrosion-resistance of thermoplastic bearing liners with shafting. This technology is ideal for chemical washdown environments, as well as those in saltwater environments. These systems also provide excellent rigidity and high load-bearing capacities.

Other types of linear guides are also available. Plain bearing guides may be appropriate for less expensive applications, while round shaft systems may be better for more expensive applications.

editor by Dream 2024-05-09

China wholesaler CHINAMFG Heavy-Duty Ball Double Rail Linear Motion Guideway Rail for Machine Tool Hgkh-C Series

Product Description

HGKH-C Series Ball Linear Xihu (West Lake) Dis. Rail

HGK series linear slide rail is a four-row single-arc tooth contact linear slide rail. At the same time, it integrates an ultra-heavy load precision linear slide rail with optimized structural design. Compared with other linear slide rails, it has improved load and rigidity; it has 4 functions. Load characteristics such as direction and automatic centering function can absorb the assembly error of the mounting surface and obtain high-precision demands. The concepts of high speed, high load, high rigidity and high precision have become the development trend of industrial products all over the world in the future. CHINAMFG four-row super-heavy load linear slide rail is a product developed based on this concept.

HGK Series Linear Slide Features

o Automatic Centering Ability

The DF (45°-45) combination from the circular arc groove, during installation, due to the elastic deformation of the steel ball and the transfer of the contact point, even if the installation surface is somewhat deviated, it can be absorbed by the inside of the line rail slider, resulting in With the effect of self-aligning ability, high-precision and stable smooth motion can be obtained.

o Interchangeable

Due to the strict control of manufacturing precision, the size of the linear slide rail can be maintained within a certain level, and the slide block is designed with a retainer to prevent the steel ball from falling off. Therefore, some series of precision are interchangeable, and customers can order slide rails according to their needs. Or sliders, the slide rails and sliders can also be stored separately to reduce storage space.

o High Rigidity In All Directions

The use of 4 rows of circular arc grooves, combined with 4 rows of steel balls and a contact angle of 45 degrees, allows the steel balls to achieve an ideal two-point contact structure, which can withstand loads from up and down and left and right directions; when necessary, preload can be applied to improve rigidity.

HGK Series Types

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Precision Automation Equipment |

|---|---|

| Material: | Steel |

| Structure: | Linear Motion Transmission |

| Installation: | Automatic Machinery |

| Driven Type: | Ball Linear Drive |

| Carrying Capacity: | Weight Level |

| Customization: |

Available

|

|

|---|

Can you describe the various mounting options and installations for linear rails in different settings?

Linear rails can be mounted in various configurations to suit different settings and applications. The choice of mounting options depends on factors such as space constraints, load requirements, and the desired motion characteristics. Here are some common mounting options and installations:

1. Horizontal Mounting: Linear rails are horizontally mounted when the desired linear motion is along the horizontal axis. This configuration is commonly used in applications such as CNC machines, where the tool needs to move horizontally across the workpiece.

2. Vertical Mounting: Vertical mounting involves installing linear rails to support vertical linear motion. This configuration is prevalent in applications like vertical machining centers, where the spindle moves vertically to perform machining operations on the workpiece.

3. Inverted Mounting: Inverted mounting is where the linear rail is installed upside down. This configuration is suitable when space limitations or specific design requirements dictate the need for the rail to be positioned below the moving component. Inverted mounting is common in some types of robotic systems.

4. Parallel Mounting: Linear rails can be mounted in parallel to support multiple carriages or moving components. This configuration is beneficial in applications where synchronized linear motion is required, such as in certain types of material handling systems or conveyor belts.

5. Cantilever Mounting: Cantilever mounting involves mounting the linear rail with one end extending beyond a support structure. This configuration is used when access to one side of the linear motion is required, such as in loading and unloading stations on manufacturing lines.

6. Tandem Mounting: Tandem mounting involves mounting multiple linear rails in tandem to share the load and provide additional support. This configuration is suitable for applications with heavy loads or long travel distances, ensuring stability and preventing deflection.

7. Floating Mounting: Floating mounting allows for some degree of flexibility in the alignment of the linear rail. This is useful in applications where there may be minor misalignments or variations in the mounting surface.

The choice of mounting option depends on the specific requirements of the application, and engineers must carefully consider factors such as load distribution, accessibility, and alignment to ensure optimal performance and longevity of the linear rail system.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

Are there specific linear rail designs for different applications, like CNC machines or automation systems?

Yes, specific linear rail designs are tailored to different applications based on the requirements of the machinery. Some notable examples include:

- CNC Machines: CNC (Computer Numerical Control) machines demand high precision and stiffness. Profiled rail systems are commonly used in CNC machines due to their exceptional accuracy, load capacity, and rigidity. These systems ensure the precise linear motion required for intricate machining processes in industries like manufacturing and prototyping.

- Automation Systems: Linear rails play a crucial role in automation systems where precise and repeatable linear motion is essential. Profiled rail systems are preferred in high-precision automation applications such as pick-and-place machines, robotic assembly lines, and conveyor systems. These systems provide the necessary accuracy and reliability for seamless automation processes.

- 3D Printers: Linear rails are used in the construction of 3D printers to facilitate the movement of print heads and build platforms. Both profiled rail and round rail systems can be suitable for different types of 3D printers, depending on factors like precision requirements and available space.

- Material Handling Systems: Round rail systems, known for their compact design and cost-effectiveness, find applications in material handling systems. These systems are suitable for applications such as packaging machinery and conveyors, where moderate precision and space efficiency are crucial.

The selection of linear rail designs is influenced by factors such as load capacity, precision, stiffness, and the specific needs of the application. Engineers choose the most appropriate linear rail system to optimize the performance of machinery in diverse industrial settings.

editor by Dream 2024-05-07

China manufacturer Linear Guideway Bearing Guide Way Precision Equipment Machine Linear Guide diy cnc linear rail

Product Description

As follows linear guide&block are in stock:(compatible with CZPT linear guide)

| GH series rail | GHR15,GHR20,GHR25,GHR30,GHR35,GHR45 |

| GHH..CA square block | GHH15CA,GHH20CA,GHH25CA,GHH30CA,GHH35CA,GHH45CA |

| GHW..CC flange block | GHW15CC,GHW20CC,GHW25CC,GHW30CC,GHW35CC,GHW45CC |

| GHH..HA lengthen | GHH20HA,GHH25HA,GHH30HA,GHH35HA,GHH45HA |

| GHW..HC lengthen | GHW15HC,GHW20HC,GHW25HC,GHW30HC,GHW35HC,GHW45HC |

| GE low assembly rail | GER15,GER20,GER25 |

| GEH..CA | GEH15CA,GEH20CA,GEH25CA |

| GEH..SA | GEH15SA,GEH20SA |

| GEW..CA | GEW15CA,GEW20CA,GEW25CA |

| MGN rail | MGNR5,MGR7,MGR9,MGR12,MGR15 |

| MGN..C | MGN5C,MGN7C,MGN9C,MGN12C,MGN15C |

| MGN..H | MGN7H,MGN9H,MGN12H,MGN15H |

| MGW rail | MGW7,MGW9,MGW12,MGW15 |

| MGW..C | MGW7C,MGW9C,MGW12C,MGW15C |

| MGW..H | MGW7H,MGW9H,MGW12H,MGW15H |

Diagram of the working principle of the rail slider

Rail structure diagram

Selection of series

GH series:Grinding Miling ,and riling machine,Lathe. Electric discharge machine,Wirecutting machine,Wood cutting machine,Precision measure equipment,Machin-e center

GE series:Automatic equipment,Semiconductor equipment,Laser engraving mac-hine,High speed transfer machine,Packing machine,Medical equipment

QE/QH series:High precision measure equipment,Semiconductor

equipment,Automatic equipment, can be widely aplied in high-tech industry required high speed,low noise,low dust generation

GR senies:CNC machining centers,Heavy duty cutting machine,CNC ginding Machine

GMN/GMW Series: Miniature device,semiconductor equipment,3Dprinter

Detailed Photos

| Brand | SHAC |

| Precision | C/H/P |

| Model | GHH/GHW/GEH/GEW/MGN/MGW |

| Size customize | Available |

| Maximum length | 4000MM-6000MM |

| Raw Materail | S55C,SCM420H |

| HS CODE | 8466939000,8483300090 |

| Items packing | Plastic bag+Cartons+Plywood boxes.According to our customer’s request. |

| Payment terms | L/C,TT,Westeb Union |

| Production lead time | Base on customer required quantity,by negotiated |

| Samples | samples and catalogue available,sample express request pay by clients |

| Application | CNC machines,machine tools,Industrial Machinery,Pringting Machine,Paper-processing machine,automatic machines,textiles machines,electronic machinery,transport machinery,Robot,etc |

Company Profile

Certifications

Our Advantages

Packaging & Shipping

Service:

1,Our Team:

We have experienced and qualified team of marketing and sales representatives to serve our valued customers with the finest products and unsurpassed service.And have professional engineers team to assessment and development the new precision products,and make the OEM customized more easily,experienced QC team to test the products quaity ensure the goods quality before delivery out.

2,Our products:

Quality is the life .We use only the best quality material to ensure the precision of our

Product.All products we sold out are strictly selected and tested by our QC department.

3,Payment:

We accept payment via TT (Bank transfer), L/C,Western Union.Paypal and other payment.

4,Shipping method:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as customer required.

To get sample or price list of linear gudies, please contact us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Original Maximum Length: | 4000mm |

|---|---|

| Raw Material: | S55c,Scm420h |

| Precision Grade: | C/H/P |

| Connect: | Available Upon Line Cutting |

| Samples: | Available |

| Application: | CNC Machines |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Using a “Traditional” Linear Rail in a 3D Printer Build

Using a “traditional” linear rail in a 3D printer build is a great way to add a bit of extra strength to your printer’s frame, but it comes with a few drawbacks. The following article will explain some of the reasons you might want to consider a sliding carriage and rail instead.

Applications

Basically, a Linear Rail System is a piece of mechanical equipment designed to sustain the motion of equipment. The system uses a combination of linear guides and bearings to maintain a steady motion.

The linear rail system is used in many industries, from manufacturing to transportation. It is important to design the system to suit the intended application. Some of the most common applications include material transfer, medical sample handling and factory automation.

The most common type of linear rail is the recirculating ball guide. Recirculating ball guides offer many advantages, including moment control, high load capacity and precision. However, there are limitations in some applications.

In the food and beverage industry, special linear bearings are necessary to handle harsh conditions and to meet health and safety standards. Some applications include weighing machines, pick and place modules, and packaging systems.

Linear rails also require precision mounting surfaces to ensure accurate motion. They are available in various lengths and are suitable for most applications.

A linear rail system can be used horizontally or vertically. They provide a smooth motion, reducing friction and minimizing wear. Linear Rail Systems can support loads ranging from a few grams to thousands of kilograms. The rail itself is made from high-strength steel and can be galvanised for added durability.

Linear Rail Systems can be used in a wide variety of industries, from pharmaceutical manufacturing to semiconductor manufacturing. The systems are easy to install and have a heavy load bearing capacity. They provide high stiffness and load capacity, and are perfect for moving loads with minimal friction. These systems also have low frictional resistance, which is important in pneumatic-driven systems.

There are several other advantages to using linear rails, including low cost, high load capacity, low friction and low maintenance. The rails are made from stainless steel or carbon steel.

CZPT linear guide rails

CZPT has a full lineup of linear guide rails, slides, and carriages to suit almost any application. Whether you’re assembling a high tech medical instrumentation system or automating your garage, CZPT has the equipment to get the job done. The company offers a wide selection of linear motion equipment ranging from mountable linear bearings to miniature guide rail and carriage assemblies.

The company also offers a full range of linear guide rails and carriages from high strength steel to high tech aluminum. The company’s extensive selection of linear motion products can be accessed through its convenient online ordering system. It also has a number of useful guides to help you choose the best equipment for your needs.

CZPT’s line of linear guide rails and carriages also includes space saving miniature guide rail and carriage assemblies. With a product lineup boasting over 500 linear motion devices, the company has something for just about every budget and need. CZPT’s line of linear guide systems is engineered to ensure maximum efficiency and reliability in an array of applications. CZPT’s linear guide products are the best in the industry. A CZPT linear guide can stand up to tearing loads and torque forces. Its superior performance can be maintained in a clean environment with proper maintenance. A well maintained rail can last for many years.

CZPT has a number of eminently sexy linear guide and carriage solutions to suit any application. You can browse by manufacturer or category to find what you’re looking for. From drilled and undrilled linear rails to carriages to linear guide slides, CZPT can help you make your next project a success. The company offers the best prices in the business and its products are made in the United States and Canada.

Sliding carriage and rail

Whether you’re looking for a new or used linear carriage and rail, there are a few things to keep in mind. For instance, you’ll need to choose a sturdy base material, like granite or steel, that can withstand the weight of the load. In addition, you’ll need to secure the linear components to the base.

Also, you’ll need a control system to regulate the carriage’s motion. These systems can be controlled by operator controls or feedback signals from sensors. If your application calls for a heavy load, you might want to consider a profiled rail.

Another option is a sleeve bearing slide. These slides are designed to be simple to operate, but they are not as durable as other slides.

A sleeve bearing slide is typically used in light-weight applications. It can be made of a variety of materials, including aluminum, steel, or stainless steel. These slides can have a ball screw drive and a linear motor.

These slides can also have rolling element bearings. These balls are used to support the load in the carriage. This decreases friction and provides a smoother motion.

In addition, these slides can be lubricated. You can find these slides in a variety of designs, including recirculating and non-recirculating. In non-recirculating designs, the rolling elements travel at half the speed of the carriage. In recirculating designs, the rolling elements follow the carriage’s looped course.

Some linear guides offer a variety of materials, including stainless steel, aluminum, and granite. These materials can be customized to match your needs. Some may also have custom-engineered features, such as a rail and bearing system, stage, and drive units. If you’re looking for a cost-effective solution, you may want to consider a custom-engineered linear slide.

Robot transport units

Adding linear movement to a Robot system is an effective way to enhance a Robot’s performance. The robot can now move larger and heavier workpieces to and from different machines, and to increase its utility. Adding linear movement also increases the number of activities that can be performed. This increases the robot’s throughput and helps to maximize the return on investment.

The Robot Transfer Unit (RTU) is an effective solution for adding linear movement to Robot systems. It increases the efficiency of 6-axis robots by allowing them to move workpieces along a moving conveyor line. RTUs are used in material handling applications such as welding, painting, inspection, and palletizing.

Robot Transfer Units can be floor-mounted, or raised above operations or the floor. This increases worker freedom of movement, while allowing for improved access to machinery by maintenance personnel. They also save floor space and can allow materials to be moved closer to the work area.

RTUs are used to carry robots between work stations and in material-handling applications. They are generally floor-mounted or can be elevated to save floor space and provide a view of the operation.

A typical RTU will include two workpiece transport units. Each workpiece transport unit includes a robotic arm, a guide rail, and a slidably mounted arm. Each workpiece transport unit also includes an electromagnet that propels the unit along the guide rail. The arm can rotate or “flip” about a horizontal axis (R) and the end effector can hold wafers (W) or rotate about a vertical axis (Z 2).

Each transport unit has a lateral outside dimension 640. This allows the unit to be slidably mounted on both sides of the guide rail structure.

Drawbacks of using “traditional” linear rail in a 3D printer build

Using a traditional linear rail in a 3D printer build isn’t for the faint of heart. If you’re building a printer for your own personal use, it’s likely you’ll have to do a bit of tinkering to get the machine working as it should. Luckily, there are many alternatives to the conventional build process. For example, you can build a machine with an aluminum extrusion instead of using the traditional molten plastic. This allows you to print a wider range of materials and improves the machine’s longevity. Alternatively, you could use an aluminum extrusion with a delrin wheel for improved print quality.

You could also build a 3D printer from scratch with a custom frame made from aluminum. The material is a good choice if you’re looking to print large format items. The material is also lightweight, which translates into improved print quality and a smoother print experience. Using an aluminum extrusion for the frame of a 3D printer could save you some serious cash, if you know what you’re doing.