Product Description

| Product Parameter | |||||

| Repeated Accuracy (mm) | ±0.01 | ||||

| Ball Screw Lead (mm) | 5 | 10 | 20 | 40 | |

| Maximum Speed (mm/s) | 250 | 500 | 1000 | 2000 | |

| Maximum Payload (kg) |

Horizontal | 120 | 110 | 75 | 22 |

| Vertical | 40 | 30 | 14 | 7 | |

| Rated Thrust (N) | 1388 | 694 | 347 | 174 | |

| Stroke Range (mm) | 50~1250 | ||||

| Motor power (W) | 400W/750W | ||||

| Screw Diameter (mm) | Ø20 | ||||

| Sliding Rail Specification | W20×H17.5 | ||||

| Coupler Specification | 12×19/14/11 | ||||

| Optical Sensor | SY-307NA-W | ||||

| Stroke (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 |

| L | 317 | 367 | 414 | 467 | 517 | 567 | 617 | 667 | 717 | 767 | 817 | 867 | 917 | 967 | 1017 | 1067 | 1117 | 1167 | 1217 | 1267 | 1317 | 1367 | 1417 | 1467 | 1517 |

| A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 |

| N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 |

| Weight (Kg) | 9.61 | 10.2 | 10.79 | 11.57 | 12.34 | 13.11 | 13.88 | 14.65 | 15.42 | 16.19 | 16.96 | 17.73 | 18.5 | 19.28 | 20.05 | 20.82 | 21.59 | 22.36 | 23.13 | 23.9 | 24.67 | 25.44 | 26.21 | 26.98 | 27.75 |

| Stroke (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 |

| L | 333.5 | 383.5 | 433.5 | 483.5 | 533.5 | 583.5 | 633.5 | 683.5 | 733.5 | 783.5 | 833.5 | 883.5 | 933.5 | 983.5 | 1033.5 | 1083.5 | 1133.5 | 1183.5 | 1233.5 | 1283.5 | 1333.5 | 1383.5 | 1433.5 | 1483.5 | 1533.5 |

| A | 0 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| N | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 16 |

| Weight (Kg) | 9.53 | 10.3 | 11.07 | 11.84 | 12.61 | 13.38 | 14.15 | 14.92 | 15.69 | 16.47 | 17.24 | 18.01 | 18.78 | 19.55 | 20.32 | 21.09 | 21.86 | 22.63 | 23.4 | 24.18 | 24.95 | 25.72 | 26.49 | 27.26 | 28.03 |

| Stroke (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 |

| L | 333.5 | 383.5 | 433.5 | 483.5 | 533.5 | 583.5 | 633.5 | 683.5 | 733.5 | 783.5 | 833.5 | 883.5 | 933.5 | 983.5 | 1033.5 | 1083.5 | 1133.5 | 1183.5 | 1233.5 | 1283.5 | 1333.5 | 1383.5 | 1433.5 | 1483.5 | 1533.5 |

| A | 0 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| N | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 16 |

| Weight (Kg) | 9.53 | 10.3 | 11.07 | 11.84 | 12.61 | 13.38 | 14.15 | 14.92 | 15.69 | 16.47 | 17.24 | 18.01 | 18.78 | 19.55 | 20.32 | 21.09 | 21.86 | 22.63 | 23.4 | 24.18 | 24.95 | 25.72 | 26.49 | 27.26 | 28.03 |

| Stroke (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 |

| L | 333.5 | 383.5 | 433.5 | 483.5 | 533.5 | 583.5 | 633.5 | 683.5 | 733.5 | 783.5 | 833.5 | 883.5 | 933.5 | 983.5 | 1033.5 | 1083.5 | 1133.5 | 1183.5 | 1233.5 | 1283.5 | 1333.5 | 1383.5 | 1433.5 | 1483.5 | 1533.5 |

| A | 0 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| N | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 16 |

| Weight (Kg) | 9.53 | 10.3 | 11.07 | 11.84 | 12.61 | 13.38 | 14.15 | 14.92 | 15.69 | 16.47 | 17.24 | 18.01 | 18.78 | 19.55 | 20.32 | 21.09 | 21.86 | 22.63 | 23.4 | 24.18 | 24.95 | 25.72 | 26.49 | 27.26 | 28.03 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Width: | 170mm |

|---|---|

| Max Stroke: | 1250mm |

| Max Payload: | 120kg |

| Applications: | Precision Industry, Semiconductor, Optical, Laser |

| Transport Package: | Carton Box |

| Specification: | Aluminum |

| Customization: |

Available

| Customized Request |

|---|

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by Dream 2024-05-07

China Custom China Factory 200mm Stroke Motorized Ball Screw Linear Slide Guide Rail for Translation Stage CNC Machine Actuator Guide

Product Description

China factory 200mm stroke motorized ball screw linear Slide Xihu (West Lake) Dis. Rail for translation stage cnc machine actuator guide

Specifications

CBX1204J-ZC linear guide is semi-sealer structure, body width 42mm, high stability,compact structure,versatility feature, suitable for normal working environment, it is convenient to use single axis or multi-axis to assemble easy functional usage robotic arms for kinds of industries.

Application Area:

Precise positioning, dispensing, spray painting, visual inspection, moving, grabbing, cutting and welding, automatic assembly, automatic locking screws, palletizing, etc. Such as: PCB board detection, optical disc stacking device, parts pick and place.

|

Model |

CBX-ZC Ball screw | Screw speed | 0-200mm/s |

| Profile width | 42mm | The vertical load (kg) | 15KG |

| Specifications of ball screw | 1204,1605,1610 | Horizontal load (kg) | 35KG |

| PositionaI accuracy | 0.03mm | Effective travel range | 0-1500mm |

The total length of 200mm strok linear guide rail is 326mm

(total length =stroke +126mm)

Get a discount

|

Related Products |

Related products

You may like

Our Services

Company Information

Our Certificate

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum+Stainless Steel |

|---|---|

| Condition: | New |

| Warranty: | 1.5 Years |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the role of linear rail materials and coatings in performance and longevity?

The materials and coatings used in the construction of linear rails play a crucial role in determining their performance and longevity. Here’s an overview of their significance:

Materials:

- High-Strength Alloys: Linear rails are often constructed using high-strength alloys, such as hardened steel or aluminum. These materials provide the necessary strength and rigidity to withstand the stresses of continuous linear motion, ensuring stability and preventing deformation under load.

- Corrosion-Resistant Materials: In environments where corrosion is a concern, linear rails may be made from corrosion-resistant materials or coated with anti-corrosive substances. Stainless steel or specialized alloys with corrosion-resistant properties enhance the longevity of the rails, particularly in industrial settings with exposure to moisture or harsh chemicals.

- Self-Lubricating Materials: Some linear rails incorporate self-lubricating materials, such as polymers with embedded solid lubricants. These materials reduce friction between the rail and carriage, improving efficiency and minimizing wear. Self-lubricating properties contribute to smoother linear motion and extend the lifespan of the rail system.

Coatings:

- Anti-Friction Coatings: Coatings with anti-friction properties, such as Teflon or other low-friction materials, are applied to reduce friction between the rail and carriage. Anti-friction coatings enhance the efficiency of the linear rail system by minimizing heat generation and wear, resulting in smoother and more reliable linear motion.

- Corrosion-Resistant Coatings: Linear rails used in corrosive environments may be coated with protective layers to resist corrosion. These coatings act as a barrier, preventing exposure to corrosive elements and preserving the structural integrity of the rail over time.

- Hard Coatings: Hard coatings, such as nitriding or various forms of surface hardening, are applied to increase the hardness and wear resistance of the rail’s surface. This protects against abrasion and extends the lifespan of the rail, especially in high-load applications.

- Dry Film Lubricants: Some coatings incorporate dry film lubricants that provide long-lasting lubrication to the rail and carriage interface. These coatings reduce friction, enhance performance, and contribute to the overall reliability of the linear rail system.

The careful selection of materials and coatings is essential for tailoring linear rails to specific application needs. By considering factors such as environmental conditions, load requirements, and desired performance characteristics, engineers can choose the most appropriate combination to optimize the performance and longevity of the linear rail system.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

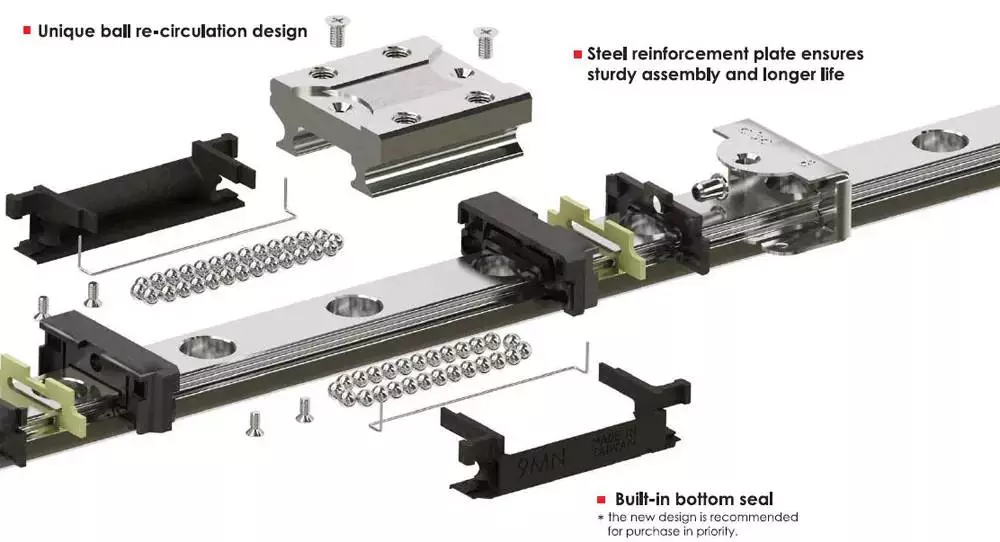

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

Can you describe the various types of linear rails, such as profiled or round rail systems?

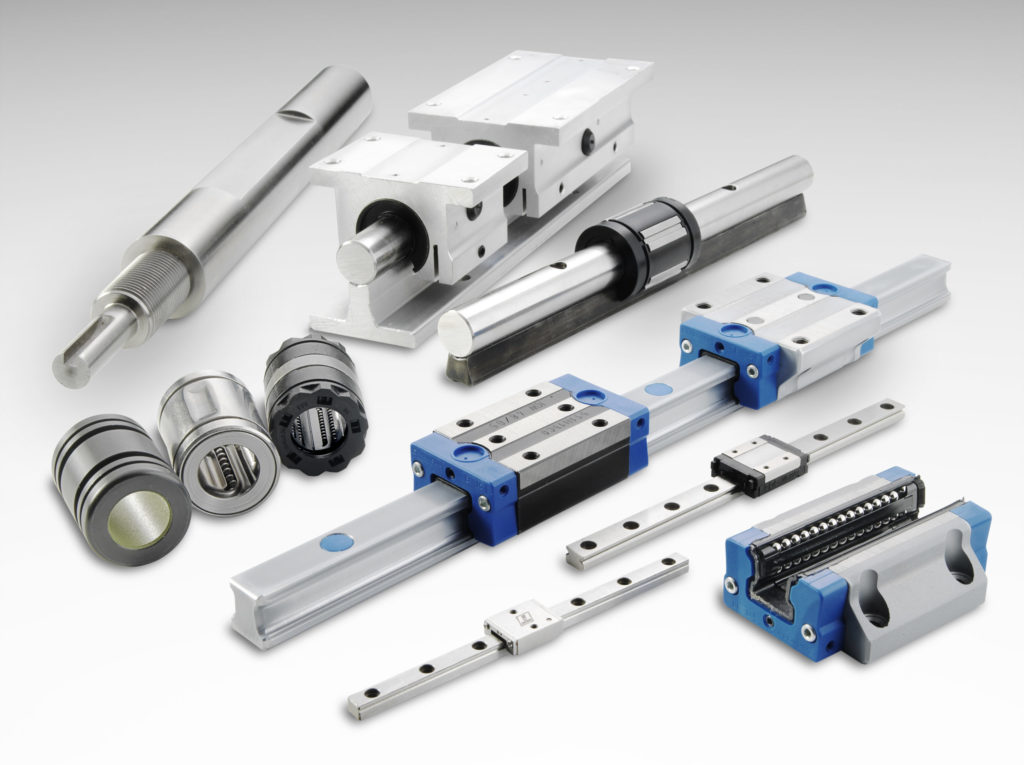

There are several types of linear rails, each with its own design and characteristics. Two common types are profiled rail systems and round rail systems:

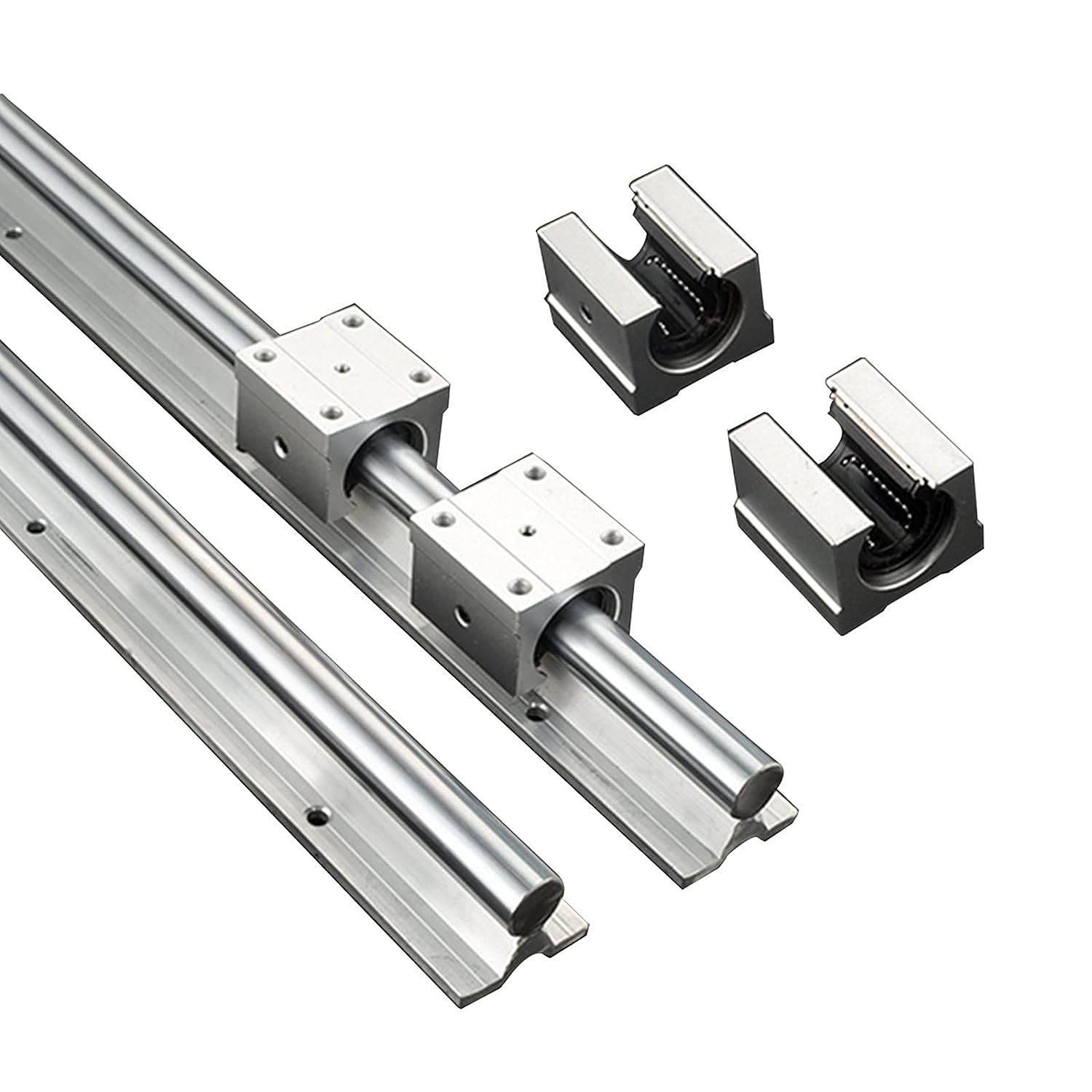

Profiled Rail Systems: Profiled rail systems consist of a rigid rail with a specially designed profile, typically featuring recirculating ball or roller bearings. The carriage, mounted on the rail, contains these bearings, providing smooth and precise linear motion. Profiled rail systems are known for their high load capacity, accuracy, and stiffness. They are commonly used in applications where precision and rigidity are critical, such as CNC machines and industrial automation systems.

Round Rail Systems: Round rail systems utilize cylindrical rails and carriages with linear bearings. These systems are often more compact and cost-effective than profiled rail systems. While they may have slightly lower load capacities and precision compared to profiled rail systems, round rail systems are suitable for applications where space is limited, and the requirements for precision are moderate. Round rail systems find use in applications such as packaging machinery, material handling, and some types of 3D printers.

Other types of linear rails include dovetail slides, boxway guides, and more, each with its own design to suit specific applications and requirements. The choice of linear rail type depends on factors such as load capacity, precision, space constraints, and cost considerations in a particular application.

editor by Dream 2024-05-02

China wholesaler Mgn15r Mgn15c Miniature Linear Guide Rail Carriage Slide Block for CNC Machine Tool linear rail ball screw kit

Product Description

Product Description

Specification

| Brand | CSZBTR |

| Model |

MGN12R MGN12C MGN12H |

| Material | stainless steel |

Other Models

| Model No. | Dimensions of Assembly (mm) |

Dimensions of Block [mm] | Dimensions of Rail (mml | Mounting Bolt for Rail |

Weight | ||||||||||||||||||

| Block

kg |

Railt | ||||||||||||||||||||||

| H | H; | N | W | B | B, | C | L | L | G | G. | Mxl | . | H | D | h | d | P | E | Imm] | ||||

| MGN5C | 6 | 1.5 | 3.5 | 12 | 8 | 2 | 9.6 | 16 | 0.8 | M2x1.5 | 1 | 5 | 3.6 | 3.6 | 0.8 | 2.4 | 15 | 5 | M2x6 | 0.008 | 0.15 | ||

| MGN7C | 8 | 1.5 | 5 | 17 | 12 | 2.5 | 8

13 |

13.5

21.8 |

22.5

30.8 |

1.2 | M2x2.5 | 1.5 | 7 | 4.8 | 4.2 | 2.3 | 2.4 | 15 | 5 | M2x6 | 0.571 | 0.22 | |

| MGN7H | 0.015 | ||||||||||||||||||||||

| MGN9C | 10 | 2 | 5.5 | 20 | 15 | 2.5 | 10

16 |

18.9 | 28.9 | 1.4 | M3x3 | 1.8 | 9 | 6.5 | 6 | 3.5 | 3.5 | 20 | 7.5 | M3x8 | 0.016 | 0.38 | |

| MGN9H | 29.9 | 39.9 | 0.026 | ||||||||||||||||||||

| MGN12C | 13 | 3 | 7.5 | 27 | 20 | 3.5 | 15

20 |

21.7

32.4 |

34.7 | 02 | M3x3.5 | 2.5 | 12 | 8 | 6 | 4.5 | 3.5 | 25 | 10 | M3x8 | 0.034 | 0.65 | |

| MGN12H | 45.4 | 0.054 | |||||||||||||||||||||

| MGN15C | 16 | 4 | 8.5 | 32 | 25 | 3.5 | 20

25 |

26.7

43.4 |

42.1

58.8 |

4.5 | M3 | M3x4 | 3 | 15 | 10 | 6 | 4.5 | 3.5 | 40 | 15 | M3x10 | 0.059 | 1.06 |

| MGN15H | 0.092 | ||||||||||||||||||||||

Company Profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit and transmission component .the growing

industrial and Favorable policy of HangZhou benefit the development of Terry Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting to 46 countries. including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out customers

with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock, No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We inspect every piece of products by ourselves before delivery.

production process

application

Packing &Delivery

Customer Praise

relared product

product-list-1.html

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Stainless Steel |

| Structure: | Tyre Crane |

| Installation: | All-Terrain Crane |

| Driven Type: | AC |

| Carrying Capacity: | Middle-Level |

| Samples: |

US$ 10.20/Piece

1 Piece(Min.Order) | |

|---|

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by Dream 2024-04-22

China high quality Hbx150mm Wide 300kg High Load Ball Screw Linear Motion Guide Rail for CNC Kit

Product Description

HBX150mm wide 300kg High load ball screw linear motion guide rail for cnc kit

Price within 300mm is $188,Each additional 100mm stroke the price increases $10

the 400mm stroke price is $188+$10=$198

Ball screw is 1605,1610,if you want 2005,2571 ball screw,the price extra added $14

Before placing an order, tell customer service the specifications of the screw:such as 1605,1610,2005,2571…

Application Area:

Precise positioning, dispensing, spray painting, visual inspection, moving, grabbing, cutting and welding, automatic assembly, automatic locking screws, palletizing, etc. Such as: PCB board detection, optical disc stacking device, parts pick and place.

|

Model |

HBX 150 Ball screw | Screw speed | 0-200mm/s |

| Profile width | 150mm | The vertical load (kg) | 150KG |

| Specifications of ball screw | 1605,1610,2005,2571 | Horizontal load (kg) | 350KG |

| PositionaI accuracy | 0.03mm | Effective travel range | 0-2500mm |

Get a discount

Related products

You may like

Our Services

Company Information

Our Certificate

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum+Stainless Steel |

|---|---|

| Structure: | . |

| Installation: | . |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do linear rails enhance the overall efficiency and accuracy of linear motion in industrial and automation systems?

Linear rails play a crucial role in enhancing the overall efficiency and accuracy of linear motion in industrial and automation systems. Their impact is significant in various aspects:

- 1. Guidance and Stability: Linear rails provide a precise path for the motion of the carriage or moving component. This guidance ensures stability and eliminates deviations, contributing to accurate and controlled linear movement in industrial applications.

- 2. Low Friction: Linear rails are designed with features to minimize friction between the rail and carriage. Low friction contributes to smoother motion, reducing wear on components and enhancing the overall efficiency of the linear motion system.

- 3. High Load Capacity: Linear rails are engineered to support high loads while maintaining structural integrity. This high load capacity is essential for industrial applications where heavy materials or equipment need to be moved with precision and accuracy.

- 4. Rigidity: The rigidity of linear rails prevents deflection or flexing during operation. This rigidity is critical for maintaining accuracy, especially in applications where precise linear motion is required for tasks like machining, assembly, and quality control.

- 5. Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial and automation systems where consistent and precise motion is essential for the success of manufacturing processes.

- 6. Integration of Smart Technologies: Advanced linear rail systems may incorporate smart technologies, such as sensors and feedback systems. These technologies enable real-time monitoring, feedback, and adjustments, further enhancing accuracy and efficiency in automated processes.

- 7. Customization for Specific Applications: Linear rails can be customized for specific industrial or automation needs. Tailoring the rail system to the unique requirements of an application ensures optimal performance and efficiency, whether in a high-speed production line or a precision laboratory setting.

- 8. Long-Term Reliability: The reliability and durability of linear rails contribute to long-term efficiency. A reliable linear motion system minimizes downtime, reduces maintenance requirements, and ensures continuous, accurate operation over an extended lifespan.

Overall, the use of linear rails in industrial and automation systems results in improved efficiency, increased productivity, and enhanced precision. Their role in providing a stable, low-friction guidance system for linear motion makes them integral components in a wide range of applications across diverse industries.

What are the typical load capacities and travel distances for linear rails?

The load capacities and travel distances for linear rails vary based on the specific design, size, and application requirements. Here are general considerations:

Load Capacities:

- Light-Duty Applications: Linear rails in smaller sizes may be suitable for light-duty applications with load capacities ranging from a few hundred pounds to a few thousand pounds. These are commonly used in applications like 3D printers and light-duty automation systems.

- Medium-Duty Applications: Linear rails in medium sizes are designed for applications with moderate load requirements. Typical load capacities for medium-duty linear rails range from a few thousand pounds to tens of thousands of pounds. These are often used in CNC machines, robotic systems, and material handling equipment.

- Heavy-Duty Applications: Larger linear rails are built for heavy-duty applications with substantial load requirements. Load capacities for heavy-duty linear rails can extend into the hundreds of thousands of pounds. These are employed in industrial machinery, aerospace testing equipment, and other heavy-duty applications.

Travel Distances:

- Short-Range Travel: Some linear rails are designed for short-range travel, with typical distances ranging from a few inches to a few feet. These are suitable for applications with limited linear motion requirements, such as in certain types of printing machinery.

- Medium-Range Travel: Linear rails for medium-range travel cover distances from a few feet to several feet. These are commonly used in applications like CNC machines and automation systems where moderate linear motion is required.

- Long-Range Travel: Linear rails with long-range travel capabilities are designed for applications where extensive linear motion is necessary. These can cover distances ranging from several feet to meters and are used in applications such as large-scale industrial automation and material handling systems.

It’s essential to consult manufacturer specifications and consider factors such as speed, acceleration, and environmental conditions when selecting linear rails to ensure they meet the specific load and travel requirements of a given application.

Can you provide examples of products or equipment that rely on linear rails for accurate linear motion?

Many products and equipment across various industries rely on linear rails for accurate linear motion. Some examples include:

- CNC Machines: CNC milling machines, lathes, and routers use linear rails to achieve precise and controlled movement of cutting tools, ensuring accurate machining processes.

- Robotic Systems: Industrial robots, collaborative robots, and robotic arms incorporate linear rails for precise and repeatable linear movement in tasks such as assembly, pick-and-place, and material handling.

- 3D Printers: Linear rails are essential components in 3D printers, enabling the precise positioning of print heads and build platforms during the additive manufacturing process.

- Automated Conveyor Systems: Linear rails contribute to the accurate movement of products on conveyor systems in industries such as logistics, manufacturing, and distribution.

- Medical Imaging Equipment: Linear rails are used in medical devices like MRI machines and CT scanners to ensure precise linear movement in the imaging process.

- Aerospace Testing Equipment: Linear rails play a crucial role in aerospace testing equipment, providing accurate linear motion for testing components and systems under various conditions.

- High-Precision Measurement Devices: Instruments used for precision measurements, such as coordinate measuring machines (CMMs), rely on linear rails to achieve accurate and repeatable positioning of measurement probes.

These examples highlight the diverse applications of linear rails across industries where precise linear motion is essential for the functionality and performance of the equipment.

editor by CX 2024-03-29

China high quality China Factory Hgw30hb Hgw35CB Hgw35hb Egh25ca Ball Screw CNC Linear Guide Rail

Product Description

China Factory HGW30HB HGW35CB HGW35HB EGH25CA Ball Screw Cnc Linear Xihu (West Lake) Dis. Rail

Product Description

Linear Sliders can be divided into 3 types: roller linear guides, cylindrical linear guides, and ball linear guides. They are used to support and guide moving parts and perform reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, and other types.

Linear Xihu (West Lake) Dis.s

It mainly consists of sliders and guide rails, and sliders are mainly used in sliding friction guide rails. Linear guide rails, also known as line rails, slide rails, linear guide rails, and linear slide rails, are used in linear reciprocating motion applications and can bear a certain torque, and can achieve high-precision linear motion under high load conditions. In the mainland, it is called linear guide rail, and in ZheJiang , it is generally called linear guide rail and linear slide rail. Usually divided into square ball linear guides, double-axis core roller linear guides, and single-axis core linear guides.

The function of linear guide rail motion is to support and guide the moving parts and make a reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, and other types. Linear bearings are mainly used in automated machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear bearings and linear axes are used together. Linear guides are mainly used in mechanical structures with high precision requirements. There is no intermediate medium between the moving elements and fixed elements of the linear guides, but rolling steel balls.

Application field

1. Linear guide rails are mainly used in automated machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guide rails and linear axes are used together.

2. Linear guide rails are mainly used in mechanical structures with relatively high precision requirements. There is no intermediate medium between the moving elements and fixed elements of the linear guide rails, but rolling steel balls are used. Because the rolling steel ball is suitable for high-speed motion, with a small friction coefficient and high sensitivity, it meets the working requirements of moving parts, such as tool holders and carriages of machine tools. If the force acting on the steel ball is too large, the steel ball will be preloaded for too long, resulting in increased movement resistance of the bracket.

Product Parameters

|

Product Name |

CHINAMFG Linear Xihu (West Lake) Dis. |

| Brand Name | HOTE BEARING |

|

Model |

CHINAMFG Linear Xihu (West Lake) Dis.&Block Full Sizes |

|

MOQ |

1 Piece |

|

Packing |

Original Color Box Packed |

|

Precision |

N / H / P / SP / UP |

|

Pre-pressing |

Z0 / Z1 / Z2 / Z3 |

Detailed Photos

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, product” life, and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback on their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings of world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Non-standard roller bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After-Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at first time, and we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Iron |

| Structure: | Hook Crane |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the reliability and durability aspects of linear rails in ensuring consistent linear movement?

The reliability and durability of linear rails are critical for ensuring consistent linear movement in various applications. Here are key aspects that contribute to their reliability and durability:

- Materials: High-quality materials, such as hardened steel or reinforced alloys, are used in the construction of linear rails. These materials provide the necessary strength, wear resistance, and durability to withstand the stresses of continuous linear motion.

- Surface Treatments: Surface treatments, including coatings and finishes, are applied to protect the linear rails from corrosion, abrasion, and other forms of wear. These treatments enhance the longevity of the rails, ensuring they maintain their performance over time.

- Lubrication: Proper lubrication is essential for reducing friction between the rail and carriage. Lubrication not only minimizes wear but also contributes to smooth and consistent linear movement. Lubrication intervals and the choice of lubricants impact the overall reliability and performance of the linear rail system.

- Sealing: Sealing mechanisms are employed to protect the internal components of the linear rail system from contaminants such as dust, debris, and moisture. Effective sealing enhances the reliability of the system by preventing damage to critical components and minimizing the risk of malfunction.

- Rigidity: The rigidity of linear rails is crucial for maintaining consistent linear movement, especially under varying loads. Rigidity prevents deflection or bending of the rail, ensuring that the carriage follows a precise and predictable path during operation.

- Load-Bearing Capacity: The load-bearing capacity of linear rails is a key factor in their reliability. Properly sized linear rails that match the application’s load requirements ensure consistent performance and prevent premature wear or failure.

- Manufacturing Precision: High manufacturing precision in the production of linear rails contributes to their reliability. Precise machining and assembly processes result in consistent dimensions and tolerances, ensuring that the rail and carriage components fit together seamlessly for reliable linear motion.

Reliability and durability go hand in hand in ensuring consistent linear movement over the lifespan of the linear rail system. Regular maintenance, including inspections, lubrication, and replacement of worn components, further contributes to the sustained reliability of linear rails in industrial and automation applications.

Can linear rails be customized or modified for unique industrial or automation needs?

Yes, linear rails can be customized or modified to meet unique industrial or automation requirements. Customization allows engineers and manufacturers to tailor linear rail systems based on specific needs. Here are some ways in which customization can be achieved:

- Length and Size: Linear rails can be customized in terms of length and size to fit the spatial constraints of a particular application. This ensures optimal use of available space and allows for seamless integration into existing machinery.

- Load Capacity: For applications with unique load requirements, linear rails can be designed or modified to accommodate higher or lower load capacities. Custom load-bearing capabilities ensure that the linear rail system meets the demands of the specific application.

- Material Selection: The choice of materials used in the construction of linear rails can be customized to address specific environmental conditions or industry standards. Different coatings or materials may be selected for applications requiring resistance to corrosion, extreme temperatures, or harsh chemicals.

- Special Coatings: Custom coatings can be applied to linear rails to enhance their performance in specific environments. For example, anti-corrosive coatings may be added for applications in corrosive or humid settings, while low-friction coatings can improve overall efficiency.

- Integration of Accessories: Customization may involve the integration of accessories such as sensors, encoders, or additional components to meet automation or monitoring requirements. This ensures that the linear rail system aligns with the overall objectives of the industrial or automation setup.

Collaboration with manufacturers or suppliers experienced in linear motion systems is crucial when considering customization. They can provide insights, design expertise, and manufacturing capabilities to deliver a tailored solution that aligns with the unique needs and challenges of a specific industrial or automation application.

Can you describe the various types of linear rails, such as profiled or round rail systems?

There are several types of linear rails, each with its own design and characteristics. Two common types are profiled rail systems and round rail systems:

Profiled Rail Systems: Profiled rail systems consist of a rigid rail with a specially designed profile, typically featuring recirculating ball or roller bearings. The carriage, mounted on the rail, contains these bearings, providing smooth and precise linear motion. Profiled rail systems are known for their high load capacity, accuracy, and stiffness. They are commonly used in applications where precision and rigidity are critical, such as CNC machines and industrial automation systems.

Round Rail Systems: Round rail systems utilize cylindrical rails and carriages with linear bearings. These systems are often more compact and cost-effective than profiled rail systems. While they may have slightly lower load capacities and precision compared to profiled rail systems, round rail systems are suitable for applications where space is limited, and the requirements for precision are moderate. Round rail systems find use in applications such as packaging machinery, material handling, and some types of 3D printers.

Other types of linear rails include dovetail slides, boxway guides, and more, each with its own design to suit specific applications and requirements. The choice of linear rail type depends on factors such as load capacity, precision, space constraints, and cost considerations in a particular application.

editor by CX 2024-01-17

China cnc 200mms high speed 500mm stroke ball screw linear guide actuator and linear guide rail for cnc diy kit supplier

Issue: New

Guarantee: 1.5 many years

Applicable Industries: Resorts, Garment Outlets, Building Material Outlets, Manufacturing Plant, Equipment Fix Shops, Meals & Beverage Manufacturing facility, Farms, Cafe, Home Use, Retail, Foodstuff Store, Printing Stores, Design works , Vitality & Mining, Foods & Beverage Outlets, Marketing Business

Excess weight (KG): 12

Movie outgoing-inspection: Presented

Equipment Examination Report: Offered

Marketing Kind: Normal Solution

Warranty of main components: 1 Calendar year

Main Components: PLC, Gearbox, Gear, Pump

Product Number: htrobot

Material: alumnium alloy

Solution title: Linear Xihu (West Lake) Dis.way Rail

Software: Automated Equipment

Type: Ballscrew or belt Pushed

Function: Higher Accuracy

Efficiency: Large Overall performance

Title: Linear Levels Xy

Structure: Ball Guide Screw

Shares: Wonderful Providing Potential

Certificate: ISO9001:2015

Coloration: Silver

Packaging Specifics: inside protective deal + carton

Our mian items contains Linear sliding table,mechanical arm, PB3 PB 3 Holdback Bearing Cam Clutch A single Way Bearing precision system, grantry robot arm and automatic transmission componebts.Our goods have been widely utilized in electronics,laser processing,welding business, Lcd, LED, PCD, Automobile, photoeletric, Semiconductor industries, specifically have advantsges in precision positioning, dispensing, workpiece clamping, dealing with, positioning and assembly, visible and radiographic testing,XYZ axis movement in mechanical tools, metal sheet slicing equipment,welding, automated up-down material for CNC equipment Ect. Detailed Photos Semi-Automatic PET Bottle Blowing Device Bottle Creating Equipment Bottle Moulding MachinePET Bottle Producing Machine is ideal for creating PET plastic containers and bottles in all designs. Size Info

| Common Environment | MF | MD | MT | |

| Dustproof | MY | ML | MC | |

| Ball screw driven | MF | MT | MY/ML | MC |

| Belt driven | MD |

Using a “Traditional” Linear Rail in a 3D Printer Build

Using a “traditional” linear rail in a 3D printer build is a great way to add a bit of extra strength to your printer’s frame, but it comes with a few drawbacks. The following article will explain some of the reasons you might want to consider a sliding carriage and rail instead.

Applications

Basically, a Linear Rail System is a piece of mechanical equipment designed to sustain the motion of equipment. The system uses a combination of linear guides and bearings to maintain a steady motion.

The linear rail system is used in many industries, from manufacturing to transportation. It is important to design the system to suit the intended application. Some of the most common applications include material transfer, medical sample handling and factory automation.

The most common type of linear rail is the recirculating ball guide. Recirculating ball guides offer many advantages, including moment control, high load capacity and precision. However, there are limitations in some applications.

In the food and beverage industry, special linear bearings are necessary to handle harsh conditions and to meet health and safety standards. Some applications include weighing machines, pick and place modules, and packaging systems.

Linear rails also require precision mounting surfaces to ensure accurate motion. They are available in various lengths and are suitable for most applications.

A linear rail system can be used horizontally or vertically. They provide a smooth motion, reducing friction and minimizing wear. Linear Rail Systems can support loads ranging from a few grams to thousands of kilograms. The rail itself is made from high-strength steel and can be galvanised for added durability.

Linear Rail Systems can be used in a wide variety of industries, from pharmaceutical manufacturing to semiconductor manufacturing. The systems are easy to install and have a heavy load bearing capacity. They provide high stiffness and load capacity, and are perfect for moving loads with minimal friction. These systems also have low frictional resistance, which is important in pneumatic-driven systems.

There are several other advantages to using linear rails, including low cost, high load capacity, low friction and low maintenance. The rails are made from stainless steel or carbon steel.

CZPT linear guide rails

CZPT has a full lineup of linear guide rails, slides, and carriages to suit almost any application. Whether you’re assembling a high tech medical instrumentation system or automating your garage, CZPT has the equipment to get the job done. The company offers a wide selection of linear motion equipment ranging from mountable linear bearings to miniature guide rail and carriage assemblies.

The company also offers a full range of linear guide rails and carriages from high strength steel to high tech aluminum. The company’s extensive selection of linear motion products can be accessed through its convenient online ordering system. It also has a number of useful guides to help you choose the best equipment for your needs.

CZPT’s line of linear guide rails and carriages also includes space saving miniature guide rail and carriage assemblies. With a product lineup boasting over 500 linear motion devices, the company has something for just about every budget and need. CZPT’s line of linear guide systems is engineered to ensure maximum efficiency and reliability in an array of applications. CZPT’s linear guide products are the best in the industry. A CZPT linear guide can stand up to tearing loads and torque forces. Its superior performance can be maintained in a clean environment with proper maintenance. A well maintained rail can last for many years.

CZPT has a number of eminently sexy linear guide and carriage solutions to suit any application. You can browse by manufacturer or category to find what you’re looking for. From drilled and undrilled linear rails to carriages to linear guide slides, CZPT can help you make your next project a success. The company offers the best prices in the business and its products are made in the United States and Canada.

Sliding carriage and rail

Whether you’re looking for a new or used linear carriage and rail, there are a few things to keep in mind. For instance, you’ll need to choose a sturdy base material, like granite or steel, that can withstand the weight of the load. In addition, you’ll need to secure the linear components to the base.

Also, you’ll need a control system to regulate the carriage’s motion. These systems can be controlled by operator controls or feedback signals from sensors. If your application calls for a heavy load, you might want to consider a profiled rail.

Another option is a sleeve bearing slide. These slides are designed to be simple to operate, but they are not as durable as other slides.

A sleeve bearing slide is typically used in light-weight applications. It can be made of a variety of materials, including aluminum, steel, or stainless steel. These slides can have a ball screw drive and a linear motor.

These slides can also have rolling element bearings. These balls are used to support the load in the carriage. This decreases friction and provides a smoother motion.

In addition, these slides can be lubricated. You can find these slides in a variety of designs, including recirculating and non-recirculating. In non-recirculating designs, the rolling elements travel at half the speed of the carriage. In recirculating designs, the rolling elements follow the carriage’s looped course.

Some linear guides offer a variety of materials, including stainless steel, aluminum, and granite. These materials can be customized to match your needs. Some may also have custom-engineered features, such as a rail and bearing system, stage, and drive units. If you’re looking for a cost-effective solution, you may want to consider a custom-engineered linear slide.

Robot transport units

Adding linear movement to a Robot system is an effective way to enhance a Robot’s performance. The robot can now move larger and heavier workpieces to and from different machines, and to increase its utility. Adding linear movement also increases the number of activities that can be performed. This increases the robot’s throughput and helps to maximize the return on investment.

The Robot Transfer Unit (RTU) is an effective solution for adding linear movement to Robot systems. It increases the efficiency of 6-axis robots by allowing them to move workpieces along a moving conveyor line. RTUs are used in material handling applications such as welding, painting, inspection, and palletizing.

Robot Transfer Units can be floor-mounted, or raised above operations or the floor. This increases worker freedom of movement, while allowing for improved access to machinery by maintenance personnel. They also save floor space and can allow materials to be moved closer to the work area.

RTUs are used to carry robots between work stations and in material-handling applications. They are generally floor-mounted or can be elevated to save floor space and provide a view of the operation.

A typical RTU will include two workpiece transport units. Each workpiece transport unit includes a robotic arm, a guide rail, and a slidably mounted arm. Each workpiece transport unit also includes an electromagnet that propels the unit along the guide rail. The arm can rotate or “flip” about a horizontal axis (R) and the end effector can hold wafers (W) or rotate about a vertical axis (Z 2).

Each transport unit has a lateral outside dimension 640. This allows the unit to be slidably mounted on both sides of the guide rail structure.

Drawbacks of using “traditional” linear rail in a 3D printer build

Using a traditional linear rail in a 3D printer build isn’t for the faint of heart. If you’re building a printer for your own personal use, it’s likely you’ll have to do a bit of tinkering to get the machine working as it should. Luckily, there are many alternatives to the conventional build process. For example, you can build a machine with an aluminum extrusion instead of using the traditional molten plastic. This allows you to print a wider range of materials and improves the machine’s longevity. Alternatively, you could use an aluminum extrusion with a delrin wheel for improved print quality.

You could also build a 3D printer from scratch with a custom frame made from aluminum. The material is a good choice if you’re looking to print large format items. The material is also lightweight, which translates into improved print quality and a smoother print experience. Using an aluminum extrusion for the frame of a 3D printer could save you some serious cash, if you know what you’re doing.

It’s a good idea to do your homework before making a purchase. The best way to avoid getting ripped off is to find a reputable manufacturer and check the credentials of the company’s products. This is especially true if you’re looking to buy a machine that can be used to build 3D models of your own designs. As with anything, buying the wrong printer for the wrong application can lead to disaster. Thankfully, you can avoid some of the pitfalls with a little research and a few recommendations. If you’re looking to build the machine of your dreams, take the time to learn what you’re doing first.

editor by czh 2023-03-20

China Customized Linear Guide Rail Shaft Rod Ball Screw CNC 16mm Bearing Rolled Thread 1.5 Years Zcfhiwin Zcfhiwin Provided OEM ODM linear rail guide

Problem: New

Warranty: 1.5 many years

Applicable Industries: Building Substance Retailers, Producing Plant, Machinery Fix Stores, Printing Retailers, Development works , Vitality & Mining

Showroom Place: None

Movie outgoing-inspection: Presented

Equipment Test Report: Not Accessible

Marketing and advertising Variety: Hot Product 2019

Guarantee of main elements: 1 Year

Core Parts: Bearing

Production Process: Rolled Thread

Material: Stainless steel, Farm devices motocultivator diesel motor walking tractor plowing spare elements Stainless metal

Length: 4000mm-5000mm, Customized Duration

kind: Ball Screw

Function: Large Accuracy

Support: OEM ODM

MOQ: ten PCS

Use: Automobile-mation Program

Brand: ZCFHiwin

Weight: 5.0kg

Ball diameter: 3.175

Soon after Guarantee Service: Online video specialized help, On the internet assist

Nearby Service Location: None

Packaging Specifics: “Standard packing or as per customers’ requirements”

Port: ZheJiang

Merchandise Description High Precision

Excellent High qualityAuthentic ExportManufacturing facility Direct IncomePersonalized CompaniesHelp for OEM/ ODM

Item Class Our Advantages Our Manufacturing unit Solution packaging FAQ Q1: Why choose CZPT Hongsheng?To supply our clients with very first-course providers in the offer of high quality ball guide screw reducing costs.Q2: How is quality ensured?All our procedures strictly adhere to ISO9001:2008 procedures. From generation to shipping and delivery, we have rigid high quality handle. Ourcompany has robust technological help and has cultivated a group of supervisors who are common with item good quality, excellent at modernconcept of management.Q3: Can You Strictly Comply with The Tolerance on The Drawing And Meet up with The Substantial Precision?Yes, we can, Minimal Costs thirty Ton Tri Axle Flat Deck Trailer Flatbed Semi Trailer we can supply large precision elements and make the areas as your drawing.This autumn: How ought to I purchase and make payment?By T/T, for samples one hundred% with the order for manufacturing, 30% paid for deposit by T/T before creation arrangement, the balance tobe compensated ahead of shipment. negotiation acknowledged.Q5: What’s your Supply Time?Common components: 7-20daysNon-normal components: fifteen-25daysWe will make the shipping and delivery as before long as attainable with the guarantee high quality.Q6: Which method of transportation would be better?In standard, Aluminum alloy relocating servo bearing rail guideway movement actuator xy linear table the item are hefty, we suggestions to make supply by sea, Also we respect your sights of other transportation as well.Q7: How to Customized-created (OEM/ODM)?If you have a new solution drawing or a sample, you should ship to us, and we can custom-created the as your needed. We will alsoprovide our professional advices of the merchandise to make the layout to be a lot more understood & improve the overall performance.

How to Get the Longest Life Out of Your Linear Rails

Whether you’re looking for the strength of steel or the convenience of aluminum, linear rails can provide you with the right choice. They can withstand both downward and lift-off loads, and they can be anchored along their full length to aluminum extrusion profiles.

Maintenance of linear rails

Depending on the environment you are using your linear rails in, it will vary as to the amount of maintenance that is required. However, there are some key steps you can take to make sure you get the longest life out of your rails.

The first step is to ensure you are installing your rails on a solid, level foundation. If your rails are not level, you may get indentations on your rails, which can result in a number of problems.

The second step is to ensure you are using the correct lubricant. The right lubricant can make all the difference in your rails life. The best lubricants are those that are designed to withstand the environment you will be using them in. Ideally, you should use light oil on ball bearing raceways.

The best way to ensure you are doing it right is to have a set of dial indicators to help you make sure that your rails are level. Also, make sure that you are not relying on the guide rail to keep your rails level. You can also take the time to use a lint free cloth to wipe down your rails.

The most important part of any linear guide is its lubrication system. Most are equipped with a lubrication mechanism that makes maintenance simple. If yours is not, then you might want to consider a grease and lubrication kit from CZPT Automation.

Low coefficient of friction

Whether you’re looking for a simple linear rail or a sophisticated rail that supports the entire machine, there are a variety of choices. Each one has its own set of advantages and disadvantages. There are also various levels of accuracy, running speed, and load bearing capacity.

For example, you may need a corrosion-resistant steel type for metalworking applications. But, the same type can have a high coefficient of friction.

To reduce friction, you can choose a chain with a low-friction top chain. These chains can achieve low coefficients of friction without lubrication.

Another option is to use a plastic roller chain. This option is ideal for applications that need minimal slippage between the surfaces. These chains are engineered to have low coefficients of friction. This is made possible through a combination of compression molding and epoxy resin polymer matrix.

The manufacturer’s catalog lists the coefficient of friction of different types of top chain. This is a good way to see the difference between a ball guide and a roller guide.

The coefficient of friction of a rolling steel ball is a good indication of its working capability. This is one of the reasons why they are used in moving parts. This is also one of the reasons why PMI’s MSA Series is engineered with a low friction coefficient.

Having a low coefficient of friction can save you money and energy. This also increases the life of the chain, motor, and other linear motion components.

Stiffness

Whether it is for machine tools or consumer applications, the stiffness of linear rails is an important factor. If a linear rail is not properly aligned, it can have a high degree of deflection. This can result in damage to the rail. The life of a linear rail also depends on a variety of factors.

If the rail is not properly aligned, the load applied to the rail will follow the surface on which it is screwed. This may lead to problems with alignment.

If the rail has a large diameter, it may be easier to align than a smaller one. It can also help to run two rails in parallel. This will minimize deflection.

The stiffness of a linear rail is also determined by its load capacity. The load capacity of a rail can range from a few grams to thousands of kilograms. The higher the load capacity, the better the rail’s stiffness.

Linear rails are typically used in high precision systems. They can withstand moment loads and overhung loads. The life of a linear rail also depends on the load capacity and frequency of use.

The stiffness of a rail can also be determined by its initial contact angle. Generally, a linear rail has a higher stiffness than a linear rod.

The stiffness of a linear rail can be measured both experimentally and with an FEA. An FEA can also be used to determine the static and dynamic behavior of a linear guideway. The results can be used to determine the stiffness of different structures.

Can be anchored along their full length to aluminum extrusion profiles

Luckily for us, CZPT offers a plethora of stuff to choose from. From the ubiquitous t-slot aluminum extrusion to the tiniest trumps, CZPT has you covered. Not only does it have a wide selection of fasteners and aluminum extrusions in stock and ready to ship, CZPT also offers a number of services and solutions to help you get the job done right. Whether you’re in the market for a new warehouse or need help designing and delivering a customized product, CZPT can help. We have a staff of skilled craftspeople who will work with you from start to finish to ensure your aluminum extrusion project is done right. No job is too big or too small for us. Our customers include manufacturers of industrial and commercial grade products, as well as small businesses and individuals looking to make a splash. From commercial kitchen equipment to industrial cabinets, we can help you turn your ideas into reality. For more information. Alternatively, visit us online to learn more about our extensive line of products and solutions. Our knowledgeable team is happy to answer any and all questions about your aluminum extrusion project, and can even help with CAD design services. Regardless of your needs, CZPT can help. A large part of our success is our ability to be a single source provider of a wide range of extrusion solutions.

Applications

Whether you need to move a small item through a manufacturing process, or a heavy load, linear rails will provide a smooth, stable motion. There are many applications for linear rails, including packaging, factory automation, medical sample handling, and more.