Product Description

3 Axis Gantry Xyz Linear Stage 100mm to 2500mm Customizable Ball Screw Linear Module Xihu (West Lake) Dis. Slide Rail for 3d Printer

Quality Control

1. ISO 9001:2000 quality management system.

2. Self design and process hardware parts, ultra accuracy control and low defective rate.

3. Self built large factory buildings equipped with totally new assembly lines, control production time accurate to hours.

4. Large scale lab room with professional machine testing system, well trained staff 360-degree inspection each machine before shipping.

Product Keywords

| Easy to Equipped | Good Price Quality Ratio | Energy Saving |

Products & Staff Pictures

FAQ

1. Q: Your products looks nice, can I get a full product catalog with specification for study?

A: Yes, send your inquiry to CHINAMFG sales team.

2. Q: Can you tell me what is your company main business?

A: We mainly design and produce linear modules/actuators/motors by self, then provide OEM and export service for overseas clients.

3. Q: Which famous enterprise use your machines?

A: In China domestic, include BYD, Foxconn, LENS Technology and HUAWEI/Apple/OPPO/VIVO etc. supply chain manufacturers are our key account.

4. Q: If so, is it possible get sample machines before trial order?

A: Yes, mail your request details to CHINAMFG sales team, we can modify the 3D drawing, prepare 1 or pair of customized sample meet your special needs.

5. Q: Good, how long is your lead-time?

A: 7 working days for sample prepare, 10-15 working days for large quantity order production. (Confirm each bill of international payment need extra 3 working days)

6. Q: Sounds good, how long is the warranty period of your machines?

A: 12-months warranty is provided for our linear modules/actuators/motors, strictly based on sales contract.

7. Q: Wow, I want to do business with your company, what kind of payment terms?

A: Sample order, trial order, repeat order, we accept T/T payment, 30% deposit when signing contract, rest amount pay before shipping. (L/C payment only available for designated countries’ client)

8. Q: What is the best shipment way for your products?

A: For sample machines, the best delivery way is through airplane transport(or land transport), takes 1 week transfer to destination airport, for large quantity goods, the best shipping way is via CHINAMFG ship(or land transport), takes 1 month to destination port, FOB HangZhou, HangZhou, HangZhou, ZheJiang or other main port in China. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | PC, LCD, PCB,PDP, Biotechnology, Semiconductor,etc |

|---|---|

| Material: | Aluminium |

| Structure: | Semi-Sealed |

| Installation: | All Automation Machines |

| Driven Type: | Servo Motor |

| Carrying Capacity: | 10 Kg |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you explain the role of linear rails in reducing friction and wear in linear motion applications?

Linear rails play a pivotal role in reducing friction and wear in linear motion applications through several key mechanisms:

- 1. Precision Design: Linear rails are precision-engineered with specific profiles and tolerances. The precise design minimizes contact points between the rail and the carriage, reducing friction and wear to a minimum during linear motion.

- 2. Rolling Contact: Many linear rails utilize rolling contact elements, such as recirculating ball bearings or roller bearings. These elements roll along the profiled surface of the rail, significantly reducing friction compared to sliding contact. Rolling contact also distributes the load evenly, further minimizing wear on specific points.

- 3. Low-Friction Coatings: Some linear rails feature low-friction coatings on their surfaces. These coatings, often made of materials like Teflon or similar compounds, create a smooth and slippery surface, reducing the coefficient of friction. This results in smoother linear motion and less wear on the rail and carriage components.

- 4. Lubrication: Proper lubrication is essential for reducing friction and wear in linear motion systems. Lubricants applied to the rolling elements or the rail surface create a thin film that separates the moving parts, minimizing direct contact and friction. Regular lubrication intervals are crucial for maintaining optimal performance and extending the lifespan of the linear rail system.

- 5. Sealing Mechanisms: Linear rails often incorporate sealing mechanisms to protect against contaminants. Dust, debris, and moisture can contribute to increased friction and wear. Effective sealing prevents the ingress of contaminants, preserving the integrity of the rail and reducing wear on critical components.

- 6. Material Selection: The choice of materials for both the rail and carriage components influences friction and wear. High-quality materials with good wear resistance, such as hardened steel or specialized alloys, contribute to the long-term durability of the linear rail system.

- 7. Regular Maintenance: Implementing a regular maintenance schedule is crucial for reducing friction and wear. Inspections, cleaning, and lubrication ensure that the linear rail system operates smoothly and efficiently. Identifying and addressing any signs of wear early can prevent more significant issues and extend the overall lifespan of the system.

By incorporating these design features and maintenance practices, linear rails effectively minimize friction and wear in linear motion applications. This not only enhances the efficiency and accuracy of the system but also contributes to the long-term reliability and durability of the linear rail.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

Can you provide examples of products or equipment that rely on linear rails for accurate linear motion?

Many products and equipment across various industries rely on linear rails for accurate linear motion. Some examples include:

- CNC Machines: CNC milling machines, lathes, and routers use linear rails to achieve precise and controlled movement of cutting tools, ensuring accurate machining processes.

- Robotic Systems: Industrial robots, collaborative robots, and robotic arms incorporate linear rails for precise and repeatable linear movement in tasks such as assembly, pick-and-place, and material handling.

- 3D Printers: Linear rails are essential components in 3D printers, enabling the precise positioning of print heads and build platforms during the additive manufacturing process.

- Automated Conveyor Systems: Linear rails contribute to the accurate movement of products on conveyor systems in industries such as logistics, manufacturing, and distribution.

- Medical Imaging Equipment: Linear rails are used in medical devices like MRI machines and CT scanners to ensure precise linear movement in the imaging process.

- Aerospace Testing Equipment: Linear rails play a crucial role in aerospace testing equipment, providing accurate linear motion for testing components and systems under various conditions.

- High-Precision Measurement Devices: Instruments used for precision measurements, such as coordinate measuring machines (CMMs), rely on linear rails to achieve accurate and repeatable positioning of measurement probes.

These examples highlight the diverse applications of linear rails across industries where precise linear motion is essential for the functionality and performance of the equipment.

editor by Dream 2024-05-16

China Standard Kt60 Serie Motorized Linear Stages Linear Modules Slide Kt6010-600A1-F0 linear rail ball screw kit

Product Description

KT60 Serie Motorized Linear Stages Linear Modules Slide KT6571-600A1-F0

Anti-Friction Mono Stage for Parking System

Material: Aluminium or steel

Structure: seal or half-seal

Driver: belt or ball screw

Features:

Lightweight & Cost reduction

Easy system installation and maintenance.

High performance of dust proof

High accuracy, High efficiency, High reliability

| Brand | TOCO |

| Model | KM ,KK, |

| Size customize | KM26,KM30,KM33,KM45,KM46,KM55,KM65 |

| HS CODE | 90019 0571 0,9571 0571 0 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T , Western Union |

| Production lead time | 15 business days for sample , 35 days for the bulk |

| Samples | Sample price range from $100to $500. sample express request pay by clients |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Specification For Single Axis Robot

An integrated system ,easy installation and maintenance ,compact and lightweight ,high accuracy, high stiffness.

This is high-precision linear module/ motorized linear guides .

Features are as follows :

1. multi-tasking design : Integrated drive with ball screw and guide rail U- references , in addition to providing precision linear motion , but also with a versatile accessory. The application of the import multipurpose design is very convenient , but also can achieve high precision linear drive demand .

2. Small and light : U type rail can be guide rail and also can take the platform structure with substantially to reduced installation Volume, and the finite element method to design the best structure , get the optimal stiffness to weight ratio. Low torque and low inertia smooth positioning exercise, can reduce energy consumption.

3.high-precision and high rigidity : according to the Deformation Analysis of the contact position of the ball by the load of all directions, that this precision linear module with high accuracy and high rigidity characteristics . The finite element method of optimal structural design, to get the best stiffness to weight ratio.

4.easy to detection and equipped : positioning accuracy , positioning repeatability , walking parallel degree and starting torque and other functions are easy to detected 5.easy to facilitate assembly and maintenance : can assemble complete without professional skilled assembly workers, good lubrication to Dust-proof, easy maintenance

Package & Shipping:

1.Package: Carton or wooden case

2.Delivery time: 15 days after receiving the deposit

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea

Our service:

1. Help customer to choose correct model, with CAD & PDF drawing for your reference.

2. Professional sales team, make your purchase smooth.

3. During warranty period, any quality problem of CZPT product, once confirmed, we will send a new 1 to replace.

Company information:

HangZhou CZPT Transmission Machinery Co., Ltd, is a specialized manufacturer in linear motion products in China, which was established in 1999. Based on the strong technical strength, outstanding quality and high capacity, we have a good reputation both in China and abroad, and now we have many customers all over the world. Our main products are ball screw, ball spline, linear guide, linear bearing, mono stage, machine tool spindle, ball screw support unit and locknut. You may find more information on our website at www.toco.tw.

FAQ

1. Service :

a. Help customer to choose correct model

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.

T/T,Paypal, Western Union is acceptable.

3.Delievery :

sample: 5-10 business days after payment confirmed.

Bulk order :10-20 workdays after deposit received .

4. Guarantee time

TOCO provides 1 year quality guarantee for the products from your purchase date, except the artificial damage.

5.After sale-service

During warranty period, any quality problem of CZPT product, once confirmed, we will send a new 1 to replace. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Anti-Static, Cold-Resistant, Corrosion-Resistant |

| Application: | Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Food Machinery, Mining Equipment, Transmission and Guidancetransmission and Guidance |

| Surface Treatment: | Polishing |

| Material: | Stainless Steel |

| Model Number: | Htb65 |

| Samples: |

US$ 120/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing the Right Type of Linear Rail for Your 3D Printer

Using a linear rail in your 3D printer is a common way to provide support for the bed, but there are some drawbacks to using this type of rail. Learn about the different types of rail and how to select the best one for your project.

Square rail

Choosing the right linear rail can bring significant advantages in cost, durability and performance. Choosing the right rail type is a key step before deciding on the overall design. Choosing the correct type will depend on your application’s requirements. The selection process involves learning from past mistakes and defining the system’s objectives. Choosing the right rail isn’t unlike choosing other components for a machine.

Unlike round rail, square rails require a flat mounting surface. Moreover, square rails can’t span gaps. The rails must be aligned perfectly to achieve the desired parallelism. Square rails also need to be lubricated properly.

Square rails are used for applications that require high load capacity. Square rails are typically used for machine tool applications. They have a greater load capacity than round rails. They can handle heavy loads and moment loads. They provide high precision and accuracy. They also have more surface contact than round rails.

Generally, square rails are more expensive than round rails. Square rails are also more prone to debris. They also need tighter parallelism than round rails. Square rails also need a straight continuous support.

Square rails have higher load capacity and precision. However, they have higher maintenance costs. Square rails also need to be installed carefully. They can be prone to misapplication. Misapplication can happen due to miscalculation or personal bias. Choosing the right rail type isn’t always the right solution for your application. It’s always best to start with preliminary calculations before deciding.

Round rails are generally faster to install. They also allow for greater ranges in rail height. They can also handle imperfect parallelism. However, they also have lower load capacity. They require more parts than square rails.

They can be installed vertically or horizontally. They are also available in different sizes. CZPT provides bearing blocks in different seals. Their bearing blocks can be purchased in long, normal or short block versions. CZPT’s long block versions have a self-lubricating option.

Round rails are more forgiving than square rails. They have less tendency to pull up. They are also less prone to deflection.

CZPT(r) T

Whether you are working in the manufacturing, automotive, pharmaceutical, or food industry, CZPT (r) T linear rail assemblies can be configured for your application. These rail assemblies are manufactured from lightweight aluminum and can be customized to your specifications. They are designed to replace recirculating ball bearings, eliminating messy oil, grease, and downtime. You can download CZPT (r) T linear rail assemblies as CAD files to facilitate customization.

There are two main types of CZPT (r) T linear rails. The T-shaped design is manufactured from hard-anodized aluminum. These linear guides are designed to be lightweight, easy to install, and durable. They are perfect for applications where speed is critical.

For more than 50 years, Sealstrip has been manufacturing packaging solutions with its patented package reclosure device. In its heyday, metal bearings were the standard for package reclosure, but they proved to be expensive and often required frequent maintenance. Fortunately, CZPT (r) T linear guide systems are a better option. They are oil free, corrosion resistant, and come with a number of functional and design features that rival metal bearings.

CZPT (r) T linear rails are easy to install and maintain, so you can focus on the task at hand. Their design is efficient, allowing for the smoothest, most precise motion. CZPT (r) T rail assemblies are also available in stainless steel, making them ideal for applications in harsh environments. These bearings have a unique split adapter that makes installation easy. They are compatible with standard ball bearings. They can carry heavy loads up to 800 pounds.

In addition to CZPT (r) T linear rails, CZPT (r) family of products includes CZPT (r) R linear plain bearings, CZPT (r) S anodized aluminum shafting, and CZPT (r) slide tables. All CZPT (r) products are designed to meet your motion control component needs. They are available from 28,000 stock items. You can also order energy chain systems and chainflex continuous flex cables. These linear guides are designed to help you get the most from your manufacturing equipment. They are the ideal way to replace recirculating ball bearings.

liding contact guides

Generally, linear guides are composed of guide rails, slide bodies and bearing inserts. These systems are widely used in different applications. They are designed to reduce friction, increase power efficiency and increase overall efficiency of units. The guide can be made of steel or aluminum. The slide can be plain surface bearing or a rolling-element bearing. These types of slides have a low frictional resistance, and can be used in high speed applications.

Sliding contact guides on linear rails have sliding contact along the entire length of the rail. The sliding contact is made by a rolling-element bearing, such as a ball, roller or cam roller. Linear bearing slides can be lubricated with grease, oil or vacuum lubricant. The use of linear bearing slides helps to minimize operating temperatures and improves overall efficiency of units.

These guides are used in applications with high precision. They are a good option in applications with limited space requirements. They also provide increased load capacity while reducing the size of the unit.

The present invention provides an alternative to the prior art linear guides. It consists of a linear guide with a replaceable bearing element. This element is removable from the slider without replacing the slide body. It also eliminates the need to replace roller elements in the bearing mechanism.

The sliding contact guides on linear rails are ideal for applications with high accuracy. They are especially useful in high speed applications. They can help grippers pick up objects more accurately. They can also be used for industrial sliding doors. They are also used in a variety of robotics applications.

The sliding contact guides on linear rails can be used in a wide range of applications, from precision machinery to computer numerical control machines. They are available in different sizes and configurations, including the MINISCALE PLUS series. They can be used in vacuum conditions of up to 10-7 mbar. They are ideal for applications requiring high accuracy and reduced power consumption.

They are available in a wide range of sizes, including 7 mm to 15 mm wide. They also have travel distances of up to 42 mm. The dynamic load capacity ranges from 207 to 1109 N. They also offer accelerations of up to 50 m/s.

Drawbacks of “traditional” linear rail in a 3D printer build

Using linear rails in a 3D printer build can increase print quality, but there are also drawbacks. There are some advantages to using linear rails, but you’ll also need to consider the cost and complexity of using them.

A traditional linear rail is a rectangular piece of steel with two dovetails along each side. It’s used to mount the carriage to the printer, and it is designed to provide smoother motion than a linear rod. Despite this, a rail can also be curved, which can create problems when printing.

Another disadvantage is that a single linear rail is more expensive than two linear rods, and it requires a physical frame for mounting. However, it can save you the cost of buying two rods and can also create a unique aesthetic for your 3D printer. Another advantage is that you can anchor the rail for greater rigidity and load-bearing capacity. You’ll also need to make sure that your rails are properly lubricated for a long life. If they aren’t, you’ll likely experience problems with print quality.

The drawbacks of using a linear rail in a 3D printer build aren’t that serious, but they’re still something to consider. If you have the budget, you may want to invest in a more capable printer, rather than in a linear rail. Also, remember that the stiffer your rails are, the less backlash you’ll experience. You’ll also avoid ringing artifacts, which will make your prints look less smooth. Regardless of the type of rail you use, it’s important to make sure that you mount it correctly.

editor by Dream 2024-05-07

China Custom China Factory 200mm Stroke Motorized Ball Screw Linear Slide Guide Rail for Translation Stage CNC Machine Actuator Guide

Product Description

China factory 200mm stroke motorized ball screw linear Slide Xihu (West Lake) Dis. Rail for translation stage cnc machine actuator guide

Specifications

CBX1204J-ZC linear guide is semi-sealer structure, body width 42mm, high stability,compact structure,versatility feature, suitable for normal working environment, it is convenient to use single axis or multi-axis to assemble easy functional usage robotic arms for kinds of industries.

Application Area:

Precise positioning, dispensing, spray painting, visual inspection, moving, grabbing, cutting and welding, automatic assembly, automatic locking screws, palletizing, etc. Such as: PCB board detection, optical disc stacking device, parts pick and place.

|

Model |

CBX-ZC Ball screw | Screw speed | 0-200mm/s |

| Profile width | 42mm | The vertical load (kg) | 15KG |

| Specifications of ball screw | 1204,1605,1610 | Horizontal load (kg) | 35KG |

| PositionaI accuracy | 0.03mm | Effective travel range | 0-1500mm |

The total length of 200mm strok linear guide rail is 326mm

(total length =stroke +126mm)

Get a discount

|

Related Products |

Related products

You may like

Our Services

Company Information

Our Certificate

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum+Stainless Steel |

|---|---|

| Condition: | New |

| Warranty: | 1.5 Years |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the role of linear rail materials and coatings in performance and longevity?

The materials and coatings used in the construction of linear rails play a crucial role in determining their performance and longevity. Here’s an overview of their significance:

Materials:

- High-Strength Alloys: Linear rails are often constructed using high-strength alloys, such as hardened steel or aluminum. These materials provide the necessary strength and rigidity to withstand the stresses of continuous linear motion, ensuring stability and preventing deformation under load.

- Corrosion-Resistant Materials: In environments where corrosion is a concern, linear rails may be made from corrosion-resistant materials or coated with anti-corrosive substances. Stainless steel or specialized alloys with corrosion-resistant properties enhance the longevity of the rails, particularly in industrial settings with exposure to moisture or harsh chemicals.

- Self-Lubricating Materials: Some linear rails incorporate self-lubricating materials, such as polymers with embedded solid lubricants. These materials reduce friction between the rail and carriage, improving efficiency and minimizing wear. Self-lubricating properties contribute to smoother linear motion and extend the lifespan of the rail system.

Coatings:

- Anti-Friction Coatings: Coatings with anti-friction properties, such as Teflon or other low-friction materials, are applied to reduce friction between the rail and carriage. Anti-friction coatings enhance the efficiency of the linear rail system by minimizing heat generation and wear, resulting in smoother and more reliable linear motion.

- Corrosion-Resistant Coatings: Linear rails used in corrosive environments may be coated with protective layers to resist corrosion. These coatings act as a barrier, preventing exposure to corrosive elements and preserving the structural integrity of the rail over time.

- Hard Coatings: Hard coatings, such as nitriding or various forms of surface hardening, are applied to increase the hardness and wear resistance of the rail’s surface. This protects against abrasion and extends the lifespan of the rail, especially in high-load applications.

- Dry Film Lubricants: Some coatings incorporate dry film lubricants that provide long-lasting lubrication to the rail and carriage interface. These coatings reduce friction, enhance performance, and contribute to the overall reliability of the linear rail system.

The careful selection of materials and coatings is essential for tailoring linear rails to specific application needs. By considering factors such as environmental conditions, load requirements, and desired performance characteristics, engineers can choose the most appropriate combination to optimize the performance and longevity of the linear rail system.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

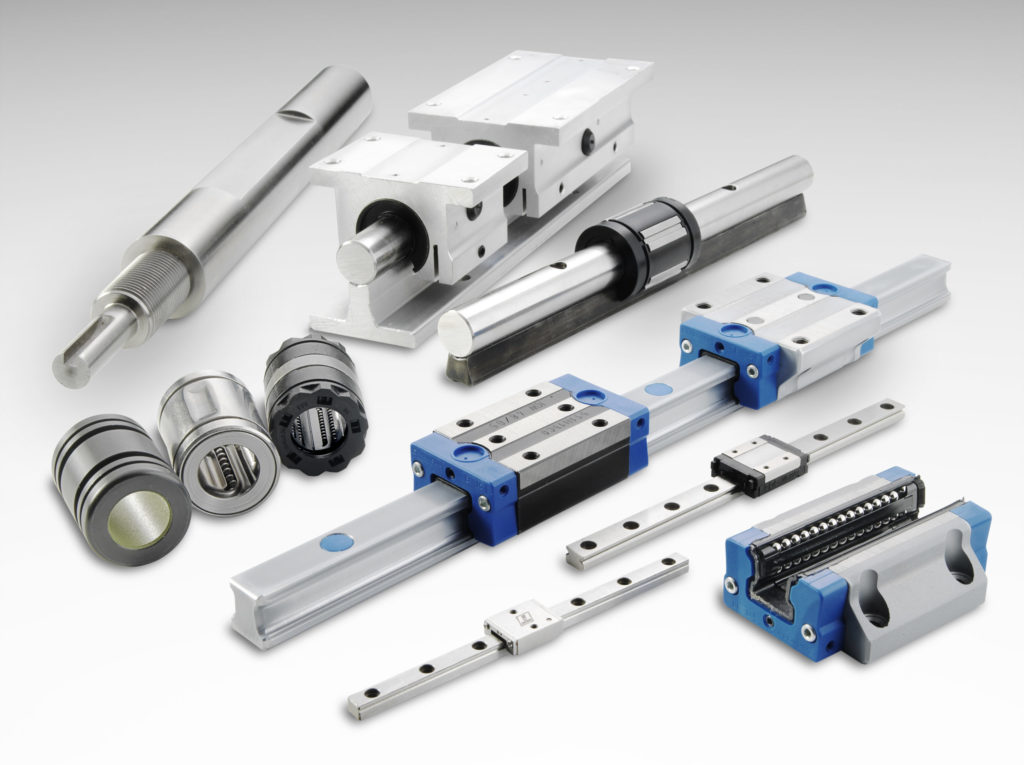

Can you describe the various types of linear rails, such as profiled or round rail systems?

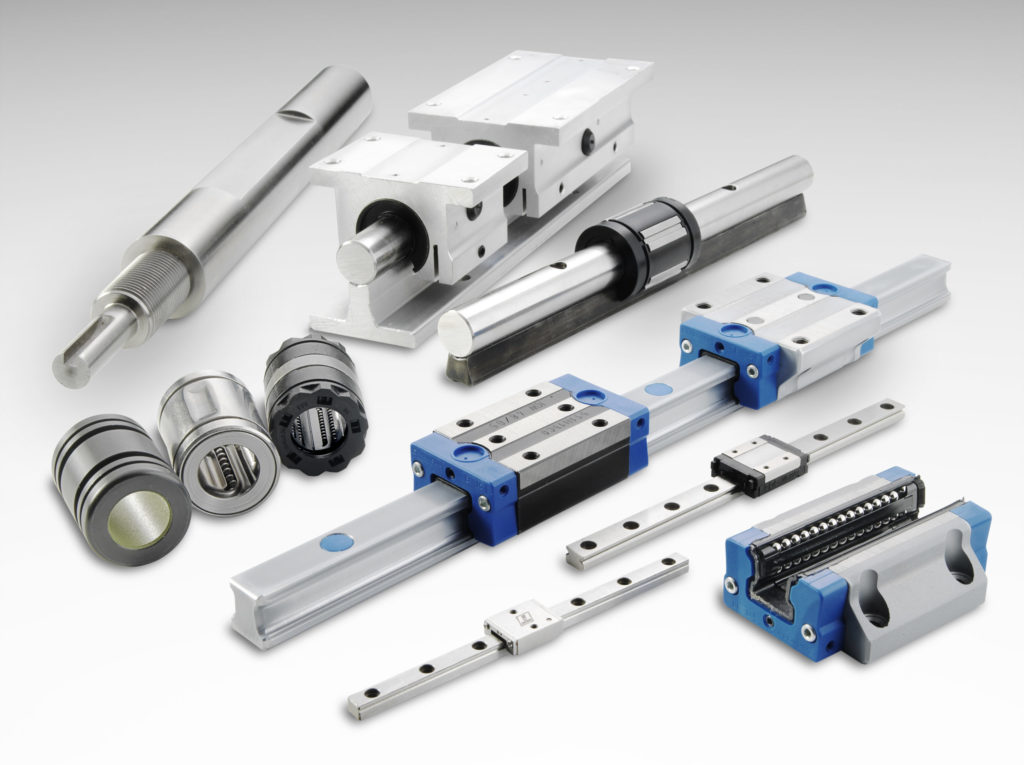

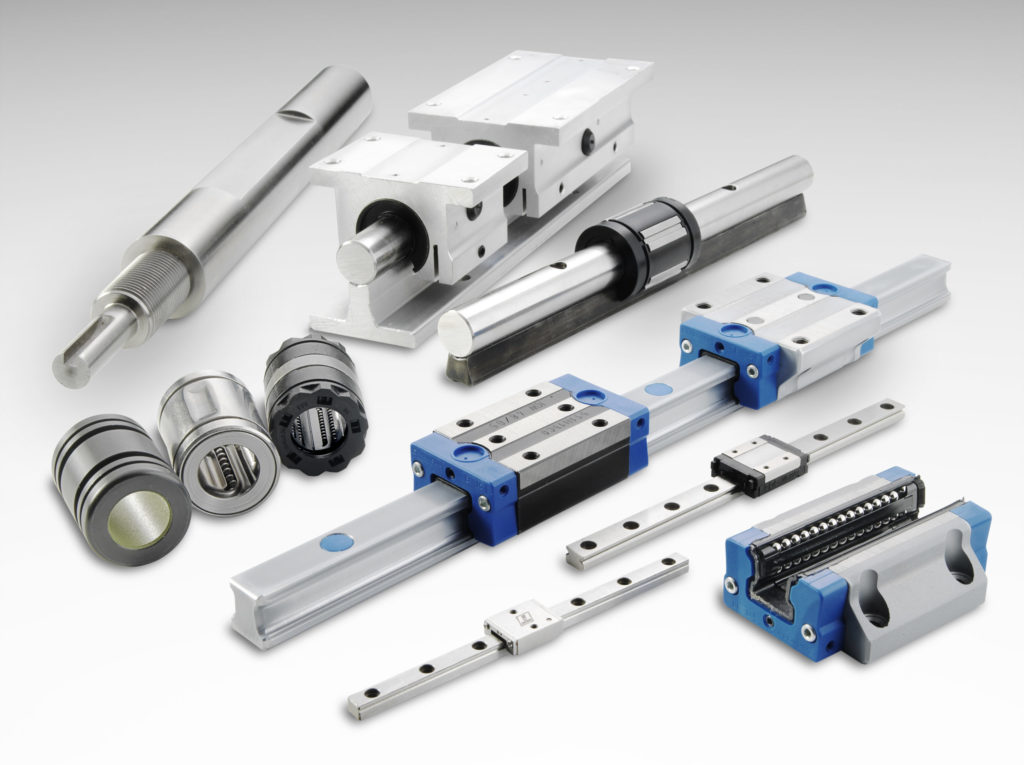

There are several types of linear rails, each with its own design and characteristics. Two common types are profiled rail systems and round rail systems:

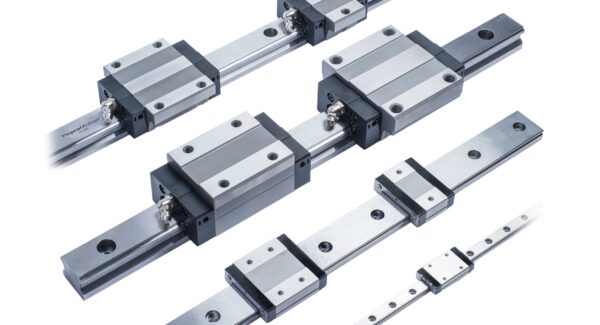

Profiled Rail Systems: Profiled rail systems consist of a rigid rail with a specially designed profile, typically featuring recirculating ball or roller bearings. The carriage, mounted on the rail, contains these bearings, providing smooth and precise linear motion. Profiled rail systems are known for their high load capacity, accuracy, and stiffness. They are commonly used in applications where precision and rigidity are critical, such as CNC machines and industrial automation systems.

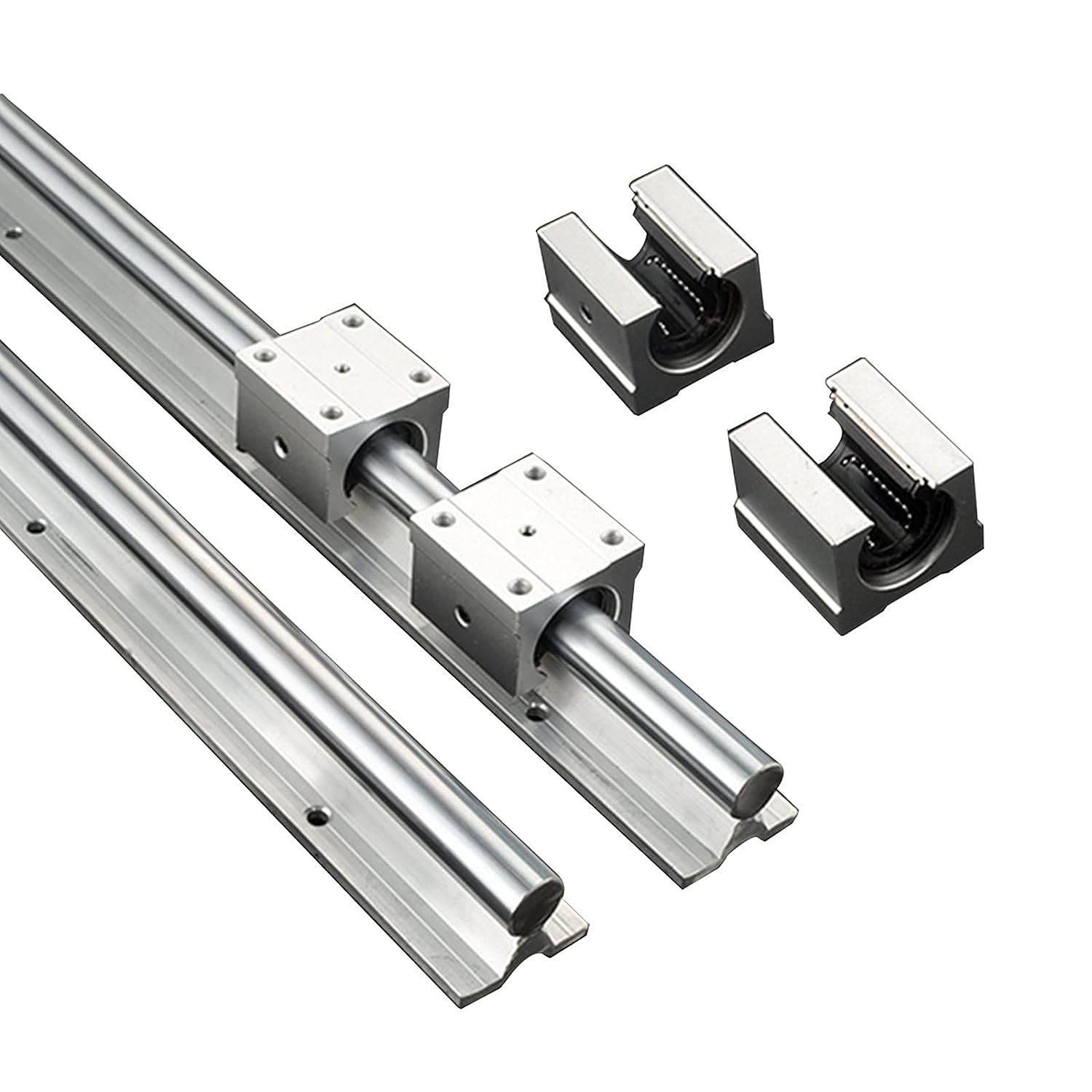

Round Rail Systems: Round rail systems utilize cylindrical rails and carriages with linear bearings. These systems are often more compact and cost-effective than profiled rail systems. While they may have slightly lower load capacities and precision compared to profiled rail systems, round rail systems are suitable for applications where space is limited, and the requirements for precision are moderate. Round rail systems find use in applications such as packaging machinery, material handling, and some types of 3D printers.

Other types of linear rails include dovetail slides, boxway guides, and more, each with its own design to suit specific applications and requirements. The choice of linear rail type depends on factors such as load capacity, precision, space constraints, and cost considerations in a particular application.

editor by Dream 2024-05-02

China wholesaler Mgn15r Mgn15c Miniature Linear Guide Rail Carriage Slide Block for CNC Machine Tool linear rail ball screw kit

Product Description

Product Description

Specification

| Brand | CSZBTR |

| Model |

MGN12R MGN12C MGN12H |

| Material | stainless steel |

Other Models

| Model No. | Dimensions of Assembly (mm) |

Dimensions of Block [mm] | Dimensions of Rail (mml | Mounting Bolt for Rail |

Weight | ||||||||||||||||||

| Block

kg |

Railt | ||||||||||||||||||||||

| H | H; | N | W | B | B, | C | L | L | G | G. | Mxl | . | H | D | h | d | P | E | Imm] | ||||

| MGN5C | 6 | 1.5 | 3.5 | 12 | 8 | 2 | 9.6 | 16 | 0.8 | M2x1.5 | 1 | 5 | 3.6 | 3.6 | 0.8 | 2.4 | 15 | 5 | M2x6 | 0.008 | 0.15 | ||

| MGN7C | 8 | 1.5 | 5 | 17 | 12 | 2.5 | 8

13 |

13.5

21.8 |

22.5

30.8 |

1.2 | M2x2.5 | 1.5 | 7 | 4.8 | 4.2 | 2.3 | 2.4 | 15 | 5 | M2x6 | 0.571 | 0.22 | |

| MGN7H | 0.015 | ||||||||||||||||||||||

| MGN9C | 10 | 2 | 5.5 | 20 | 15 | 2.5 | 10

16 |

18.9 | 28.9 | 1.4 | M3x3 | 1.8 | 9 | 6.5 | 6 | 3.5 | 3.5 | 20 | 7.5 | M3x8 | 0.016 | 0.38 | |

| MGN9H | 29.9 | 39.9 | 0.026 | ||||||||||||||||||||

| MGN12C | 13 | 3 | 7.5 | 27 | 20 | 3.5 | 15

20 |

21.7

32.4 |

34.7 | 02 | M3x3.5 | 2.5 | 12 | 8 | 6 | 4.5 | 3.5 | 25 | 10 | M3x8 | 0.034 | 0.65 | |

| MGN12H | 45.4 | 0.054 | |||||||||||||||||||||

| MGN15C | 16 | 4 | 8.5 | 32 | 25 | 3.5 | 20

25 |

26.7

43.4 |

42.1

58.8 |

4.5 | M3 | M3x4 | 3 | 15 | 10 | 6 | 4.5 | 3.5 | 40 | 15 | M3x10 | 0.059 | 1.06 |

| MGN15H | 0.092 | ||||||||||||||||||||||

Company Profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit and transmission component .the growing

industrial and Favorable policy of HangZhou benefit the development of Terry Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting to 46 countries. including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out customers

with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock, No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We inspect every piece of products by ourselves before delivery.

production process

application

Packing &Delivery

Customer Praise

relared product

product-list-1.html

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Stainless Steel |

| Structure: | Tyre Crane |

| Installation: | All-Terrain Crane |

| Driven Type: | AC |

| Carrying Capacity: | Middle-Level |

| Samples: |

US$ 10.20/Piece

1 Piece(Min.Order) | |

|---|

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by Dream 2024-04-22

China Hot selling China Manufacturing Egh20SA Egh25SA Linear Guide Slide Table Ball Screw Motion Rail

Product Description

China Manufacturing EGH20SA EGH25SA Linear Xihu (West Lake) Dis. Slide Table Ball Screw Motion Rail

Product Description

Linear Sliders can be divided into 3 types: roller linear guides, cylindrical linear guides, and ball linear guides. They are used to support and guide moving parts and perform reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, and other types.

Linear Xihu (West Lake) Dis.s

It mainly consists of sliders and guide rails, and sliders are mainly used in sliding friction guide rails. Linear guide rails, also known as line rails, slide rails, linear guide rails, and linear slide rails, are used in linear reciprocating motion applications and can bear a certain torque, and can achieve high-precision linear motion under high load conditions. In the mainland, it is called linear guide rail, and in ZheJiang , it is generally called linear guide rail and linear slide rail. Usually divided into square ball linear guides, double-axis core roller linear guides, and single-axis core linear guides.

The function of linear guide rail motion is to support and guide the moving parts and make a reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, and other types. Linear bearings are mainly used in automated machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear bearings and linear axes are used together. Linear guides are mainly used in mechanical structures with high precision requirements. There is no intermediate medium between the moving elements and fixed elements of the linear guides, but rolling steel balls.

Application field

1. Linear guide rails are mainly used in automated machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guide rails and linear axes are used together.

2. Linear guide rails are mainly used in mechanical structures with relatively high precision requirements. There is no intermediate medium between the moving elements and fixed elements of the linear guide rails, but rolling steel balls are used. Because the rolling steel ball is suitable for high-speed motion, with a small friction coefficient and high sensitivity, it meets the working requirements of moving parts, such as tool holders and carriages of machine tools. If the force acting on the steel ball is too large, the steel ball will be preloaded for too long, resulting in increased movement resistance of the bracket.

Product Parameters

|

Product Name |

CHINAMFG Linear Xihu (West Lake) Dis. |

| Brand Name | HOTE BEARING |

|

Model |

CHINAMFG Linear Xihu (West Lake) Dis.&Block Full Sizes |

|

MOQ |

1 Piece |

|

Packing |

Original Color Box Packed |

|

Precision |

N / H / P / SP / UP |

|

Pre-pressing |

Z0 / Z1 / Z2 / Z3 |

Detailed Photos

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, product” life, and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback on their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings of world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Non-standard roller bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After-Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at first time, and we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Steel |

| Structure: | Tyre Crane |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the reliability and durability aspects of linear rails in ensuring consistent linear movement?

The reliability and durability of linear rails are critical for ensuring consistent linear movement in various applications. Here are key aspects that contribute to their reliability and durability:

- Materials: High-quality materials, such as hardened steel or reinforced alloys, are used in the construction of linear rails. These materials provide the necessary strength, wear resistance, and durability to withstand the stresses of continuous linear motion.

- Surface Treatments: Surface treatments, including coatings and finishes, are applied to protect the linear rails from corrosion, abrasion, and other forms of wear. These treatments enhance the longevity of the rails, ensuring they maintain their performance over time.

- Lubrication: Proper lubrication is essential for reducing friction between the rail and carriage. Lubrication not only minimizes wear but also contributes to smooth and consistent linear movement. Lubrication intervals and the choice of lubricants impact the overall reliability and performance of the linear rail system.

- Sealing: Sealing mechanisms are employed to protect the internal components of the linear rail system from contaminants such as dust, debris, and moisture. Effective sealing enhances the reliability of the system by preventing damage to critical components and minimizing the risk of malfunction.

- Rigidity: The rigidity of linear rails is crucial for maintaining consistent linear movement, especially under varying loads. Rigidity prevents deflection or bending of the rail, ensuring that the carriage follows a precise and predictable path during operation.

- Load-Bearing Capacity: The load-bearing capacity of linear rails is a key factor in their reliability. Properly sized linear rails that match the application’s load requirements ensure consistent performance and prevent premature wear or failure.

- Manufacturing Precision: High manufacturing precision in the production of linear rails contributes to their reliability. Precise machining and assembly processes result in consistent dimensions and tolerances, ensuring that the rail and carriage components fit together seamlessly for reliable linear motion.

Reliability and durability go hand in hand in ensuring consistent linear movement over the lifespan of the linear rail system. Regular maintenance, including inspections, lubrication, and replacement of worn components, further contributes to the sustained reliability of linear rails in industrial and automation applications.

What are the typical load capacities and travel distances for linear rails?

The load capacities and travel distances for linear rails vary based on the specific design, size, and application requirements. Here are general considerations:

Load Capacities:

- Light-Duty Applications: Linear rails in smaller sizes may be suitable for light-duty applications with load capacities ranging from a few hundred pounds to a few thousand pounds. These are commonly used in applications like 3D printers and light-duty automation systems.

- Medium-Duty Applications: Linear rails in medium sizes are designed for applications with moderate load requirements. Typical load capacities for medium-duty linear rails range from a few thousand pounds to tens of thousands of pounds. These are often used in CNC machines, robotic systems, and material handling equipment.

- Heavy-Duty Applications: Larger linear rails are built for heavy-duty applications with substantial load requirements. Load capacities for heavy-duty linear rails can extend into the hundreds of thousands of pounds. These are employed in industrial machinery, aerospace testing equipment, and other heavy-duty applications.

Travel Distances:

- Short-Range Travel: Some linear rails are designed for short-range travel, with typical distances ranging from a few inches to a few feet. These are suitable for applications with limited linear motion requirements, such as in certain types of printing machinery.

- Medium-Range Travel: Linear rails for medium-range travel cover distances from a few feet to several feet. These are commonly used in applications like CNC machines and automation systems where moderate linear motion is required.

- Long-Range Travel: Linear rails with long-range travel capabilities are designed for applications where extensive linear motion is necessary. These can cover distances ranging from several feet to meters and are used in applications such as large-scale industrial automation and material handling systems.

It’s essential to consult manufacturer specifications and consider factors such as speed, acceleration, and environmental conditions when selecting linear rails to ensure they meet the specific load and travel requirements of a given application.

What industries and machinery commonly use linear rails for precise linear movement?

Linear rails find widespread use in various industries and machinery where precise linear movement is crucial. Some common applications include:

- Manufacturing Machinery: Linear rails are integral components in CNC machines, milling machines, lathes, and other manufacturing equipment. They ensure accurate and repeatable motion for precise machining processes.

- Robotics: Linear rails play a key role in robotic systems, providing the necessary guidance and precision for the movement of robot arms and other robotic components.

- Automation Systems: Industries employing automated systems, such as conveyor systems and pick-and-place machines, often utilize linear rails to achieve precise linear movement in the automation process.

- 3D Printing: Linear rails contribute to the accuracy and stability of 3D printers by facilitating the precise movement of print heads and build platforms.

- Medical Devices: Linear rails are used in medical equipment such as imaging devices, diagnostic instruments, and robotic-assisted surgery systems, where precise linear motion is critical.

- Aerospace: The aerospace industry employs linear rails in various applications, including aircraft manufacturing and testing equipment, to ensure precision in movement and positioning.

- Semiconductor Manufacturing: Linear rails are used in semiconductor manufacturing equipment for precise movement in processes such as wafer handling and inspection.

These examples demonstrate the versatility of linear rails across different industries, highlighting their importance in applications that demand accurate and reliable linear motion.

editor by CX 2024-04-17

China Good quality Manufacturer Customized Ball Screw Linear Slide Guide Rail

Product Description

Our company is a manufacturer specialized in aluminum, the aluminum industry is very professional, and because we are direct selling so also very have the advantage in terms of price, our products are promised specification product delivery in 5 days, we can also open mold customized according to customer requirements, we will according to customer demand for the logistics to find the best the most suitable logistics.

Product Detail

|

Temper |

T3-T8 |

|||

|

Standard |

GB5237-2008 or other International standards |

|||

|

Accessories |

Kingloon or Other supplier appointed by customer |

|||

|

Deep Processing |

CNC / Cutting / Welding / Punching / Checking / Tapping / Drilling / Milling |

|||

|

Fabrication |

Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Welding→ |

|||

|

Surface Treatment |

Powder coating,Fluorocaben coating,Anodizing,Polish,Electrophoresis |

|||

|

QC System |

Inspection before shipment |

|||

|

Payment term |

1. T/T: 30% deposit, the balance will be paid before delivery; |

|||

|

One stop service |

Design-Making mold-Extruding-Machining-Packing-Delivery |

|||

|

Profile type |

1. Window and door profiles; |

|||

ZheJiang COMMON ALUMINUM INDUSTRY PRODUCTS COMPANY is 1 of the leader aluminum industry in Europe,provide first-class services of aluminum industry,design,production ,manufacture and inspection.We introduced Germany High-tech professional technology and make production according to international quality management system ISO9001-2000,passed the international aluminum products quality certification.And acceptance of the customized 6063 aluminum profile and suitable accessories.

RFQ:

Q1: What’s the standard length of your aluminium profiles be shipping?

A: The standard length of aluminium profiles is 6meter, we can cut to specific length as you need.

Q2: What’s your MOQ?

A: We can accept trial orders for prototype, there are plenty of stocks in factory, and can be shipped very fast.

Q3: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10-12 um. Yes, we can do 15um and above.

Q4: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q5: What’s the lead time for small order and mass production?

A: 1~3 working days for small order, and 3~15 working days for mass production of material.

Q6: What certification do you have? What’s your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q7: What’s the packing way?

A: Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Material: | Galavanised Steel |

| Connection: | Male |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the reliability and durability aspects of linear rails in ensuring consistent linear movement?

The reliability and durability of linear rails are critical for ensuring consistent linear movement in various applications. Here are key aspects that contribute to their reliability and durability:

- Materials: High-quality materials, such as hardened steel or reinforced alloys, are used in the construction of linear rails. These materials provide the necessary strength, wear resistance, and durability to withstand the stresses of continuous linear motion.

- Surface Treatments: Surface treatments, including coatings and finishes, are applied to protect the linear rails from corrosion, abrasion, and other forms of wear. These treatments enhance the longevity of the rails, ensuring they maintain their performance over time.

- Lubrication: Proper lubrication is essential for reducing friction between the rail and carriage. Lubrication not only minimizes wear but also contributes to smooth and consistent linear movement. Lubrication intervals and the choice of lubricants impact the overall reliability and performance of the linear rail system.

- Sealing: Sealing mechanisms are employed to protect the internal components of the linear rail system from contaminants such as dust, debris, and moisture. Effective sealing enhances the reliability of the system by preventing damage to critical components and minimizing the risk of malfunction.

- Rigidity: The rigidity of linear rails is crucial for maintaining consistent linear movement, especially under varying loads. Rigidity prevents deflection or bending of the rail, ensuring that the carriage follows a precise and predictable path during operation.

- Load-Bearing Capacity: The load-bearing capacity of linear rails is a key factor in their reliability. Properly sized linear rails that match the application’s load requirements ensure consistent performance and prevent premature wear or failure.

- Manufacturing Precision: High manufacturing precision in the production of linear rails contributes to their reliability. Precise machining and assembly processes result in consistent dimensions and tolerances, ensuring that the rail and carriage components fit together seamlessly for reliable linear motion.

Reliability and durability go hand in hand in ensuring consistent linear movement over the lifespan of the linear rail system. Regular maintenance, including inspections, lubrication, and replacement of worn components, further contributes to the sustained reliability of linear rails in industrial and automation applications.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

How do linear rails differ from other linear motion components like linear guides or bearings?

While linear rails, linear guides, and bearings are all components used in linear motion systems, they differ in their design, functions, and applications:

Linear Rails: Linear rails typically consist of a long, rigid rail and a carriage that moves along the rail. The rail has a specially designed profile to provide guidance, and the carriage supports and carries the load. Linear rails are known for their ability to handle high loads, offer precise linear motion, and reduce friction for smooth movement.

Linear Guides: Linear guides encompass a broader category that includes linear rails. Linear guides refer to any mechanism that guides linear motion. Linear rails are a specific type of linear guide with a distinctive profile. Linear guides, in a general sense, can include other mechanisms like dovetail slides, boxway guides, and more, each with its own design and application.

Bearings: Bearings are components that reduce friction between moving parts and support radial or axial loads. While linear rails may incorporate bearings within their design, bearings, in a broader sense, can be standalone components used to support rotating or linear motion. Linear bearings, for example, specifically support linear motion and may be used independently or as part of a linear rail system.

In summary, linear rails are a specific type of linear guide with a defined rail and carriage design, whereas linear guides encompass a broader category. Bearings, on the other hand, are components that reduce friction and support loads, and linear bearings specifically cater to linear motion.

editor by CX 2024-03-27

China CTH12 High Quality Precision 0.01 Automation Linear Rail Slide Ball Screw Linear linear rail guide

Condition: New

Guarantee: 6 Months

Applicable Industries: Hotels, Garment Stores, Building Substance Outlets, Manufacturing Plant, Equipment Mend Stores, Meals & Beverage Factory, Cafe, Home Use, Retail, Meals Store, Printing Retailers, Development works , Vitality & Mining, Foods & Beverage Outlets, Other, Advertising Business

Bodyweight (KG): 10

Online video outgoing-inspection: Presented

Machinery Check Report: Not Offered

Advertising and marketing Kind: New Solution 2571

Warranty of core components: 1 12 months

Main Parts: Strain vessel

Model Number: CTH12

Application: Automated System

push manner: Ball screw type module

velocity: -1600mm/s

Repeatability: +-.01

stroke: fifty-1250mm

greatest payload, Large Accuracy Ball Screw SFU1204 horizontal: thirty-110kg

highest payload, vertical: 8-33kg

suitable motor brand name: Mitsubishi, Panasonic, Delta

MOQ: 1

Product Index

| Small | Medium | Large | |

| CTH | CTH4, CTH5 | CTH8, CTH12 | |

| CTY | CTY4, CTY5 | CTY8 | |

| PFTH | PFTH6M | PFTH10, PFTH11, PFTH13, PFTH14 | PFTH17, PFTH22, PFTH17M, PFTH22M |

| KH | KH50, KH60 | KH86 | |

| PFTB | PFTB6 | PFTB10, PFTB11, PFTB14M | PFTB17M, Trend substantial precision planantery reduction gearbox transmission gearbox auxiliary gearbox driving equipment hollow gear reducer PFTB22M |

| BH | BH65 | BH85 | BH110 |

| BCH | BCH6M | BCH11, BCH14 | BCH17 |

| BCB | BCB6 | BCB14 | BCB17 |

Choosing the Right Type of Linear Rail for Your 3D Printer

Using a linear rail in your 3D printer is a common way to provide support for the bed, but there are some drawbacks to using this type of rail. Learn about the different types of rail and how to select the best one for your project.

Square rail

Choosing the right linear rail can bring significant advantages in cost, durability and performance. Choosing the right rail type is a key step before deciding on the overall design. Choosing the correct type will depend on your application’s requirements. The selection process involves learning from past mistakes and defining the system’s objectives. Choosing the right rail isn’t unlike choosing other components for a machine.

Unlike round rail, square rails require a flat mounting surface. Moreover, square rails can’t span gaps. The rails must be aligned perfectly to achieve the desired parallelism. Square rails also need to be lubricated properly.

Square rails are used for applications that require high load capacity. Square rails are typically used for machine tool applications. They have a greater load capacity than round rails. They can handle heavy loads and moment loads. They provide high precision and accuracy. They also have more surface contact than round rails.

Generally, square rails are more expensive than round rails. Square rails are also more prone to debris. They also need tighter parallelism than round rails. Square rails also need a straight continuous support.

Square rails have higher load capacity and precision. However, they have higher maintenance costs. Square rails also need to be installed carefully. They can be prone to misapplication. Misapplication can happen due to miscalculation or personal bias. Choosing the right rail type isn’t always the right solution for your application. It’s always best to start with preliminary calculations before deciding.

Round rails are generally faster to install. They also allow for greater ranges in rail height. They can also handle imperfect parallelism. However, they also have lower load capacity. They require more parts than square rails.

They can be installed vertically or horizontally. They are also available in different sizes. CZPT provides bearing blocks in different seals. Their bearing blocks can be purchased in long, normal or short block versions. CZPT’s long block versions have a self-lubricating option.

Round rails are more forgiving than square rails. They have less tendency to pull up. They are also less prone to deflection.

CZPT(r) T

Whether you are working in the manufacturing, automotive, pharmaceutical, or food industry, CZPT (r) T linear rail assemblies can be configured for your application. These rail assemblies are manufactured from lightweight aluminum and can be customized to your specifications. They are designed to replace recirculating ball bearings, eliminating messy oil, grease, and downtime. You can download CZPT (r) T linear rail assemblies as CAD files to facilitate customization.

There are two main types of CZPT (r) T linear rails. The T-shaped design is manufactured from hard-anodized aluminum. These linear guides are designed to be lightweight, easy to install, and durable. They are perfect for applications where speed is critical.

For more than 50 years, Sealstrip has been manufacturing packaging solutions with its patented package reclosure device. In its heyday, metal bearings were the standard for package reclosure, but they proved to be expensive and often required frequent maintenance. Fortunately, CZPT (r) T linear guide systems are a better option. They are oil free, corrosion resistant, and come with a number of functional and design features that rival metal bearings.

CZPT (r) T linear rails are easy to install and maintain, so you can focus on the task at hand. Their design is efficient, allowing for the smoothest, most precise motion. CZPT (r) T rail assemblies are also available in stainless steel, making them ideal for applications in harsh environments. These bearings have a unique split adapter that makes installation easy. They are compatible with standard ball bearings. They can carry heavy loads up to 800 pounds.

In addition to CZPT (r) T linear rails, CZPT (r) family of products includes CZPT (r) R linear plain bearings, CZPT (r) S anodized aluminum shafting, and CZPT (r) slide tables. All CZPT (r) products are designed to meet your motion control component needs. They are available from 28,000 stock items. You can also order energy chain systems and chainflex continuous flex cables. These linear guides are designed to help you get the most from your manufacturing equipment. They are the ideal way to replace recirculating ball bearings.

liding contact guides

Generally, linear guides are composed of guide rails, slide bodies and bearing inserts. These systems are widely used in different applications. They are designed to reduce friction, increase power efficiency and increase overall efficiency of units. The guide can be made of steel or aluminum. The slide can be plain surface bearing or a rolling-element bearing. These types of slides have a low frictional resistance, and can be used in high speed applications.

Sliding contact guides on linear rails have sliding contact along the entire length of the rail. The sliding contact is made by a rolling-element bearing, such as a ball, roller or cam roller. Linear bearing slides can be lubricated with grease, oil or vacuum lubricant. The use of linear bearing slides helps to minimize operating temperatures and improves overall efficiency of units.

These guides are used in applications with high precision. They are a good option in applications with limited space requirements. They also provide increased load capacity while reducing the size of the unit.

The present invention provides an alternative to the prior art linear guides. It consists of a linear guide with a replaceable bearing element. This element is removable from the slider without replacing the slide body. It also eliminates the need to replace roller elements in the bearing mechanism.

The sliding contact guides on linear rails are ideal for applications with high accuracy. They are especially useful in high speed applications. They can help grippers pick up objects more accurately. They can also be used for industrial sliding doors. They are also used in a variety of robotics applications.

The sliding contact guides on linear rails can be used in a wide range of applications, from precision machinery to computer numerical control machines. They are available in different sizes and configurations, including the MINISCALE PLUS series. They can be used in vacuum conditions of up to 10-7 mbar. They are ideal for applications requiring high accuracy and reduced power consumption.

They are available in a wide range of sizes, including 7 mm to 15 mm wide. They also have travel distances of up to 42 mm. The dynamic load capacity ranges from 207 to 1109 N. They also offer accelerations of up to 50 m/s.

Drawbacks of “traditional” linear rail in a 3D printer build

Using linear rails in a 3D printer build can increase print quality, but there are also drawbacks. There are some advantages to using linear rails, but you’ll also need to consider the cost and complexity of using them.

A traditional linear rail is a rectangular piece of steel with two dovetails along each side. It’s used to mount the carriage to the printer, and it is designed to provide smoother motion than a linear rod. Despite this, a rail can also be curved, which can create problems when printing.