Product Description

Product Description

|

Stock |

yes |

|

Delivery time |

5-7 days |

|

Used |

building industry machinery |

Company Profile

In 2013, 1 associates decided to create an innovative sales service of bearings to satisfy diffierent kinds of application.

In order to supply even more stable quality to our vast customers, we established a factory in HangZhou city, ZHangZhoug province, China, near HangZhou and ZheJiang port, which has recognized by special ISO. The various bearings we produce there have been inspected and confirmed by SGS to be RoHS compliant.

In order to satisfy our customer’s diffierent industrial requirement: Advises, quick quotations, quick delievery, difficullt sourcing bearing products, the best suitable bearing(price, quality), We are working with over 300 suppliers to make sure to get the perfect part for you. We strive to offer the most precise and most suitable bearing for each part.

We Registered “GNYAR” in 2014, registered “MAJC” in 2018, both was received in high-performance praise, and earned high reputation among customers from motorcycle parts, auto parts and embroidery machine spare parts, Power tools, agricultural machine, bicycle, Semiconductor Facilities. Fitness Equipments, Toys, fishing, industrial using design.

After years of development, we believe that by establishing a mutually beneficial relationship with our customers we can both continue to grow and prosper, we wish and hope to always grant you satisfaction.

Product application

Certifications

Packaging & Shipping

FAQ

Q1: Is sample free of charge?

A: Sample fee will be returned in the 1st PI payment .

Q2: How long it takes to ship goods to my country?

A: We have inventory for samples, normally 7 days to arrive at your office.

Q3: How is MOQ?

A: 500pcs with customized logo and color.

Q4: How long it takes to make a customized sample?

A: Normally the leadtime is 2-3 weeks since it requires logo tooling and color adjustment.

Q5: how about quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Steel |

| Structure: | Container Crane |

| Installation: | All-Terrain Crane |

| Driven Type: | Hydraulic |

| Carrying Capacity: | Special Weight Level |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the role of linear rail materials and coatings in performance and longevity?

The materials and coatings used in the construction of linear rails play a crucial role in determining their performance and longevity. Here’s an overview of their significance:

Materials:

- High-Strength Alloys: Linear rails are often constructed using high-strength alloys, such as hardened steel or aluminum. These materials provide the necessary strength and rigidity to withstand the stresses of continuous linear motion, ensuring stability and preventing deformation under load.

- Corrosion-Resistant Materials: In environments where corrosion is a concern, linear rails may be made from corrosion-resistant materials or coated with anti-corrosive substances. Stainless steel or specialized alloys with corrosion-resistant properties enhance the longevity of the rails, particularly in industrial settings with exposure to moisture or harsh chemicals.

- Self-Lubricating Materials: Some linear rails incorporate self-lubricating materials, such as polymers with embedded solid lubricants. These materials reduce friction between the rail and carriage, improving efficiency and minimizing wear. Self-lubricating properties contribute to smoother linear motion and extend the lifespan of the rail system.

Coatings:

- Anti-Friction Coatings: Coatings with anti-friction properties, such as Teflon or other low-friction materials, are applied to reduce friction between the rail and carriage. Anti-friction coatings enhance the efficiency of the linear rail system by minimizing heat generation and wear, resulting in smoother and more reliable linear motion.

- Corrosion-Resistant Coatings: Linear rails used in corrosive environments may be coated with protective layers to resist corrosion. These coatings act as a barrier, preventing exposure to corrosive elements and preserving the structural integrity of the rail over time.

- Hard Coatings: Hard coatings, such as nitriding or various forms of surface hardening, are applied to increase the hardness and wear resistance of the rail’s surface. This protects against abrasion and extends the lifespan of the rail, especially in high-load applications.

- Dry Film Lubricants: Some coatings incorporate dry film lubricants that provide long-lasting lubrication to the rail and carriage interface. These coatings reduce friction, enhance performance, and contribute to the overall reliability of the linear rail system.

The careful selection of materials and coatings is essential for tailoring linear rails to specific application needs. By considering factors such as environmental conditions, load requirements, and desired performance characteristics, engineers can choose the most appropriate combination to optimize the performance and longevity of the linear rail system.

What is the impact of proper installation and maintenance on the performance and lifespan of linear rails?

The proper installation and maintenance of linear rails have a significant impact on their performance and lifespan. Here’s how:

Proper Installation:

- Alignment: Correct alignment during installation is crucial for the optimal performance of linear rails. Misalignment can lead to increased friction, wear, and decreased accuracy. Proper alignment ensures smooth and precise linear motion.

- Lubrication: Adequate lubrication is essential to reduce friction between the rail and carriage, preventing premature wear. Proper lubrication during installation sets the foundation for sustained performance and longevity.

- Tightening: Proper tightening of bolts and fasteners during installation ensures the stability and rigidity of the linear rail system. Loose connections can lead to vibrations, affecting accuracy and potentially causing damage over time.

Maintenance:

- Regular Inspection: Periodic inspections allow for the early detection of issues such as wear, misalignment, or contamination. Timely identification of problems enables corrective measures to be taken before they escalate.

- Cleaning: Keeping linear rails clean from debris and contaminants is essential for preventing damage and maintaining smooth motion. Regular cleaning, especially in industrial environments, contributes to the longevity of the system.

- Lubrication Maintenance: Continuous lubrication maintenance is crucial for reducing friction and preventing premature wear. Regularly checking and replenishing lubricants help ensure optimal performance over the lifespan of the linear rails.

Proper installation and proactive maintenance contribute to the overall reliability, accuracy, and longevity of linear rails. Neglecting these aspects can result in decreased performance, increased wear, and a shorter lifespan of the linear motion system.

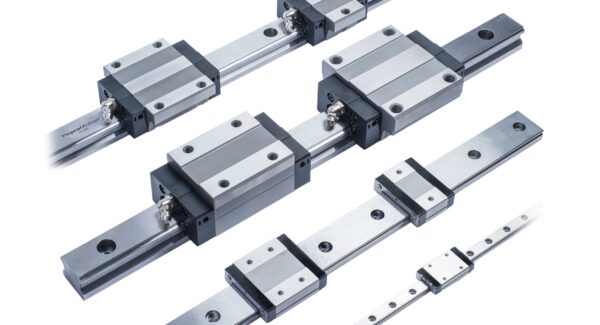

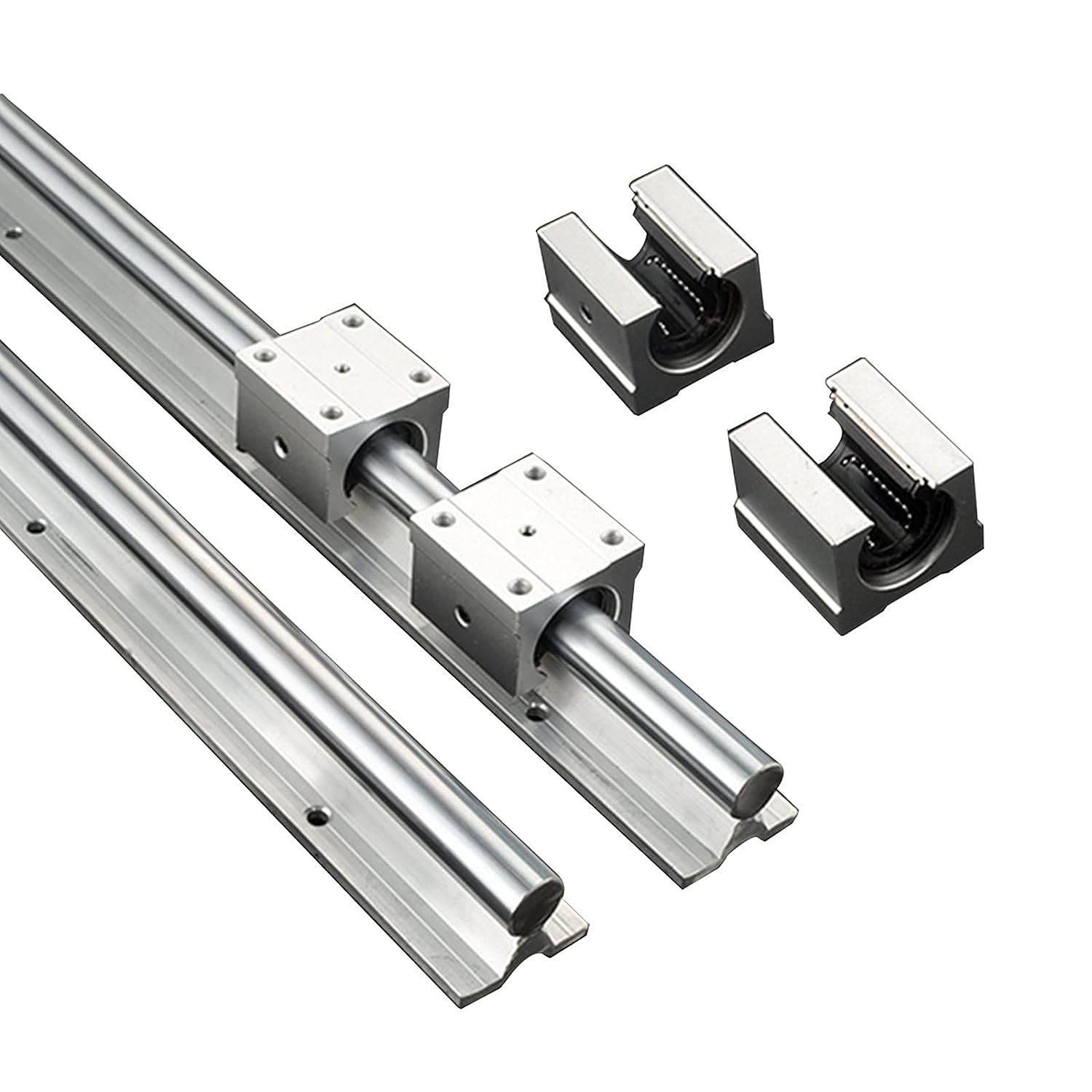

What are linear rails, and how are they used in linear motion systems?

Linear rails, also known as linear guides or linear slides, are mechanical components used in linear motion systems to facilitate smooth and precise movement along a straight path. They typically consist of a rail and a carriage. The rail is a long, rigid structure with a specially designed profile, while the carriage is mounted on the rail and holds the load to be moved.

Linear rails are widely used in various applications, including manufacturing machinery, robotics, 3D printers, and automated systems. They provide guidance and support to the moving components, minimizing friction and ensuring accurate and repeatable motion. The design of linear rails allows for high load-carrying capacity and can accommodate different types of loads, such as radial or axial loads.

Linear motion systems incorporating linear rails offer advantages such as improved precision, reduced wear and tear, and increased efficiency in comparison to traditional sliding mechanisms. The choice of linear rails depends on factors such as load capacity, speed, accuracy requirements, and environmental conditions in the specific application.

editor by Dream 2024-04-26