Product Description

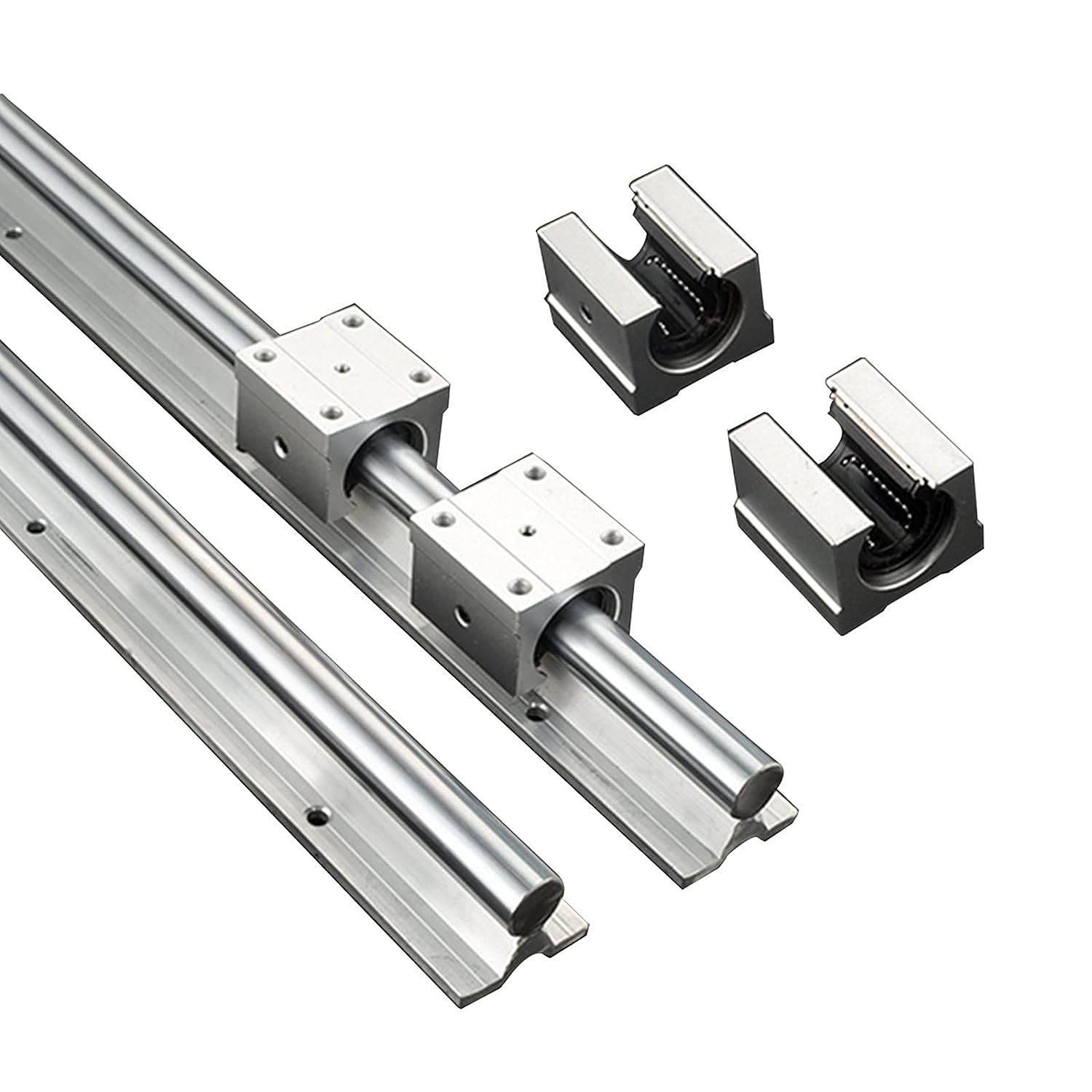

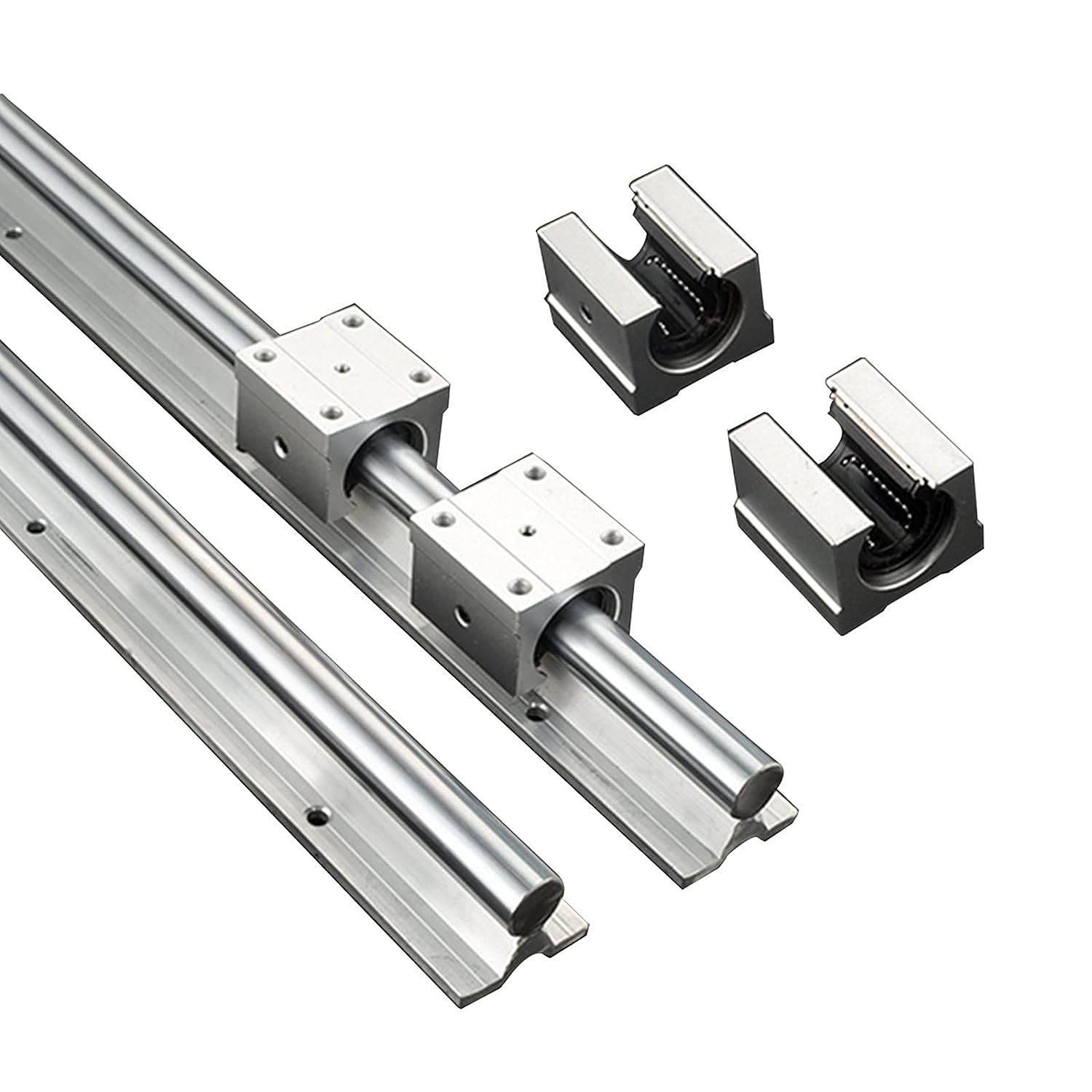

KL/KLL Four-way Equal-load Heavy-duty Wide Roller Linear Motion Xihu (West Lake) Dis.

Feature 1: The sliding rail and the sliding block are in contact with each other through balls, so the shaking is small, which is suitable for equipment with precision requirements.

Feature 2: Because of the point-to-surface contact, the frictional resistance is very small, and fine movements can be performed to achieve high-precision positioning of control devices, etc.

Feature 3: Because the ball has its own rolling groove, the force on the rotating surface will be dispersed, so it has a larger allowable load.

Feature 4: The linear guide is not easy to generate frictional heat during operation, and is not easy to be deformed by heat, so it is suitable for high-speed motion.

Application:

Automation equipment, high-speed transportation equipment, precision measuring instruments, semiconductor equipment, woodworking machinery

SJAG-KL ( Four Directional Equal Load Wide Type )

| Model | Component size(mm) | Slider size (mm) | |||||||||||||||

| H | H1 | N | W | B | B1 | C | C1 | L1 | L | K1 | G | M | T | T1 | H2 | H3 | |

| SJAG 25KL | 36 | 5.5 | 23.5 | 70 | 57 | 6.5 | 45 | 40 | 64.5 81 71 01 93 79 106.5 11068 139.8 |

97.9 | 15.75 | 12 | M8 | 9.5 | 10 | 6.2 | 6 |

| SJAG 25KLL | 81 | 114.4 | 24 | ||||||||||||||

| SJAG 30KL | 42 | 6 | 31 | 90 | 72 | 9 | 52 | 44 | 71 | 109.8 | 17.5 | 12 | M10 | 9.5 | 10 | 6.5 | 10.8 |

| SJAG 30KLL | 93 | 131.8 | 28.5 | ||||||||||||||

| SJAG 35KL | 48 | 6.5 | 33 | 100 | 82 | 9 | 62 | 52 | 79 | 124 | 16.5 | 12 | M10 | 12 | 13 | 9 | 12.6 |

| SJAG35KLL | 106.5 | 151.5 | 30.25 | ||||||||||||||

| SJAG45KL | 60 | 8 | 37.5 | 120 | 100 | 10 | 80 | 60 | 106 | 153.2 | 21 | 12.9 | M12 | 14 | 15 | 10 | 14 |

| SJAG45KLL | 139.8 | 187 | 37.9 | ||||||||||||||

| SJAG 55KL | 70 | 10 | 43.5 | 140 | 116 | 12 | 95 | 70 | 125.5 | 183.7 | 27.75 | 12.9 | M14 | 16 | 17 | 12 | 17.5 |

| SJAG55KLL | 173.8 | 232 | 5109 | ||||||||||||||

| SJAG 65KL | 90 | 12 | 53.5 | 170 | 142 | 14 | 110 | 82 | 160 | 232 | 40.8 | 12.9 | M16 | 22 | 23 | 15 | 15 |

| SJAG 65KLL | 223 | 295 | 7203 | ||||||||||||||

| SJAG85KLL | 110 | 15 | 65 | 215 | 185 | – | 140 | 70 | 254 | 349 | – | 14 | M20 | 24 | 26 | 21 | – |

| SJAG 100KLL | 120 | 15 | 75 | 250 | 220 | – | 200 | 100 | 286 | 394 | – | 16 | M20 | 25 | 30 | 23 | – |

| SJAG 125KLL | 160 | 24.5 | 97.5 | 320 | 270 | – | 205 | 102.5 | 360 | 491 | – | 16 | M20 | 30 | 45 | 23 | – |

KL Type Xihu (West Lake) Dis. Rail Sub-Mounting Connection Dimensions

| Rail size(mm) | Fixing bolt size of slide rail | Basic dynamic load rating | Basic static load rating | Allowable static moment | Weight | |||||||||

| WR | HR | D | h | d | P | E | (mm) | C(kN) | Co(kN) | MR | MP | MY | Slide | Rail |

| 23 | 23.6 | 11 | g | 7 | 30 | 20 | M6×20 | 27.7 | 57.1 | 0.758 | 0.605 | 0.605 | 0.67 | 3.08 |

| 33.9 | 73.4 | 0.975 | 0.991 | 0.991 | 0.86 | |||||||||

| 28 | 28 | 14 | 12 | 9 | 40 | 20 | M8×25 | 39.1 | 82.1 | 1.445 | 1.06 | 1.06 | 1.06 | 4.41 |

| 48.1 | 105 | 1.846 | 1.712 | 1.712 | 1.42 | |||||||||

| 34 | 30.2 | 14 | 12 | 9 | 40 | 20 | M8×25 | 57.9 | 105.2 | 2.17 | 1.44 | 1.44 | 1.61 | 6.06 |

| 73.1 | 142 | 2.93 | 2.6 | 2.6 | 2.21 | |||||||||

| 45 | 38 | 20 | 17 | 14 | 52.5 | 22.5 | M12×35 | 92.6 | 178.8 | 4.52 | 3.05 | 3.05 | 3.22 | 9.97 |

| 116 | 230.9 | 6.33 | 5.47 | 5.47 | 4.41 | |||||||||

| 53 | 44 | 23 | 20 | 16 | 60 | 30 | M14×45 | 130.5 | 252 | 8.01 | 5.4 | 5.4 | 5.18 | 13.98 |

| 167.8 | 348 | 11.15 | 10.25 | 10.25 | 7.34 | |||||||||

| 63 | 53 | 26 | 22 | 18 | 75 | 35 | M16×50 | 213 | 411.6 | 16.2 | 11.59 | 11.59 | 11.04 | 20.22 |

| 275.3 | 572.7 | 22.55 | 22.17 | 22.17 | 15.75 | |||||||||

| 85 | 73 | 35 | 28 | 24 | 9o | 45 | M20 | 460 | 945.2 | 45600 | 45600 | 51420 | 21.6 | 35.2 |

| 100 | 8o | 39 | 32 | 26 | 105 | 52.5 | M24 | 547 | 1330 | 61200 | 61200 | 73140 | 31.5 | 46.8 |

| 125 | 115 | 48 | 45 | 33 | 120 | 60 | M30 | 1040 | 1924 | 123176 | 123176 | 114138 | 65.5 | 84.6 |

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Precision Automation Equipment |

|---|---|

| Material: | Steel |

| Structure: | Linear Motion Transmission |

| Installation: | Automatic Machinery |

| Driven Type: | Roller Linear Drive |

| Carrying Capacity: | Weight Level |

| Customization: |

Available

|

|

|---|

How do linear rails enhance the overall efficiency and accuracy of linear motion in industrial and automation systems?

Linear rails play a crucial role in enhancing the overall efficiency and accuracy of linear motion in industrial and automation systems. Their impact is significant in various aspects:

- 1. Guidance and Stability: Linear rails provide a precise path for the motion of the carriage or moving component. This guidance ensures stability and eliminates deviations, contributing to accurate and controlled linear movement in industrial applications.

- 2. Low Friction: Linear rails are designed with features to minimize friction between the rail and carriage. Low friction contributes to smoother motion, reducing wear on components and enhancing the overall efficiency of the linear motion system.

- 3. High Load Capacity: Linear rails are engineered to support high loads while maintaining structural integrity. This high load capacity is essential for industrial applications where heavy materials or equipment need to be moved with precision and accuracy.

- 4. Rigidity: The rigidity of linear rails prevents deflection or flexing during operation. This rigidity is critical for maintaining accuracy, especially in applications where precise linear motion is required for tasks like machining, assembly, and quality control.

- 5. Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial and automation systems where consistent and precise motion is essential for the success of manufacturing processes.

- 6. Integration of Smart Technologies: Advanced linear rail systems may incorporate smart technologies, such as sensors and feedback systems. These technologies enable real-time monitoring, feedback, and adjustments, further enhancing accuracy and efficiency in automated processes.

- 7. Customization for Specific Applications: Linear rails can be customized for specific industrial or automation needs. Tailoring the rail system to the unique requirements of an application ensures optimal performance and efficiency, whether in a high-speed production line or a precision laboratory setting.

- 8. Long-Term Reliability: The reliability and durability of linear rails contribute to long-term efficiency. A reliable linear motion system minimizes downtime, reduces maintenance requirements, and ensures continuous, accurate operation over an extended lifespan.

Overall, the use of linear rails in industrial and automation systems results in improved efficiency, increased productivity, and enhanced precision. Their role in providing a stable, low-friction guidance system for linear motion makes them integral components in a wide range of applications across diverse industries.

How do innovations and advancements in linear rail technology impact their use?

Innovations and advancements in linear rail technology have a profound impact on their use, influencing performance, efficiency, and application possibilities. Here are key ways in which technological advancements impact the use of linear rails:

- 1. Enhanced Precision: Advancements in manufacturing processes and materials contribute to higher precision in the design and production of linear rails. This results in improved accuracy and repeatability in linear motion applications, making them suitable for tasks requiring intricate and precise movements, such as in CNC machining and 3D printing.

- 2. Increased Load Capacities: Ongoing innovations allow for the development of linear rails with increased load-bearing capabilities. This is particularly beneficial in industries and applications where heavy loads need to be moved with precision, such as in industrial automation and material handling systems.

- 3. Integration of Smart Technologies: The integration of smart technologies, such as sensors and feedback systems, enhances the monitoring and control capabilities of linear rail systems. This facilitates real-time data collection, predictive maintenance, and improved overall system efficiency, particularly in automated and Industry 4.0 settings.

- 4. Energy Efficiency: Innovations in lubrication systems and materials contribute to increased energy efficiency in linear rail operation. Reduced friction and optimized designs help minimize energy consumption, making linear rails more environmentally friendly and cost-effective over their lifespan.

- 5. Customization and Modularity: Advanced manufacturing techniques enable greater customization and modularity in linear rail systems. Engineers can tailor linear rails to specific application needs, adjusting parameters such as length, load capacity, and material composition for optimal performance in diverse industrial and automation scenarios.

- 6. Durability and Longevity: Continuous improvements in materials and surface treatments enhance the durability and longevity of linear rails. This is particularly beneficial in applications where reliability and minimal maintenance are critical, such as in aerospace testing equipment and high-precision manufacturing.

Overall, innovations in linear rail technology contribute to a broader range of applications, improved performance metrics, and the ability to meet the evolving needs of diverse industries. As technology continues to advance, the versatility and effectiveness of linear rails in various industrial and automation settings are likely to expand even further.

Are there specific linear rail designs for different applications, like CNC machines or automation systems?

Yes, specific linear rail designs are tailored to different applications based on the requirements of the machinery. Some notable examples include:

- CNC Machines: CNC (Computer Numerical Control) machines demand high precision and stiffness. Profiled rail systems are commonly used in CNC machines due to their exceptional accuracy, load capacity, and rigidity. These systems ensure the precise linear motion required for intricate machining processes in industries like manufacturing and prototyping.

- Automation Systems: Linear rails play a crucial role in automation systems where precise and repeatable linear motion is essential. Profiled rail systems are preferred in high-precision automation applications such as pick-and-place machines, robotic assembly lines, and conveyor systems. These systems provide the necessary accuracy and reliability for seamless automation processes.

- 3D Printers: Linear rails are used in the construction of 3D printers to facilitate the movement of print heads and build platforms. Both profiled rail and round rail systems can be suitable for different types of 3D printers, depending on factors like precision requirements and available space.

- Material Handling Systems: Round rail systems, known for their compact design and cost-effectiveness, find applications in material handling systems. These systems are suitable for applications such as packaging machinery and conveyors, where moderate precision and space efficiency are crucial.

The selection of linear rail designs is influenced by factors such as load capacity, precision, stiffness, and the specific needs of the application. Engineers choose the most appropriate linear rail system to optimize the performance of machinery in diverse industrial settings.

editor by Dream 2024-04-26