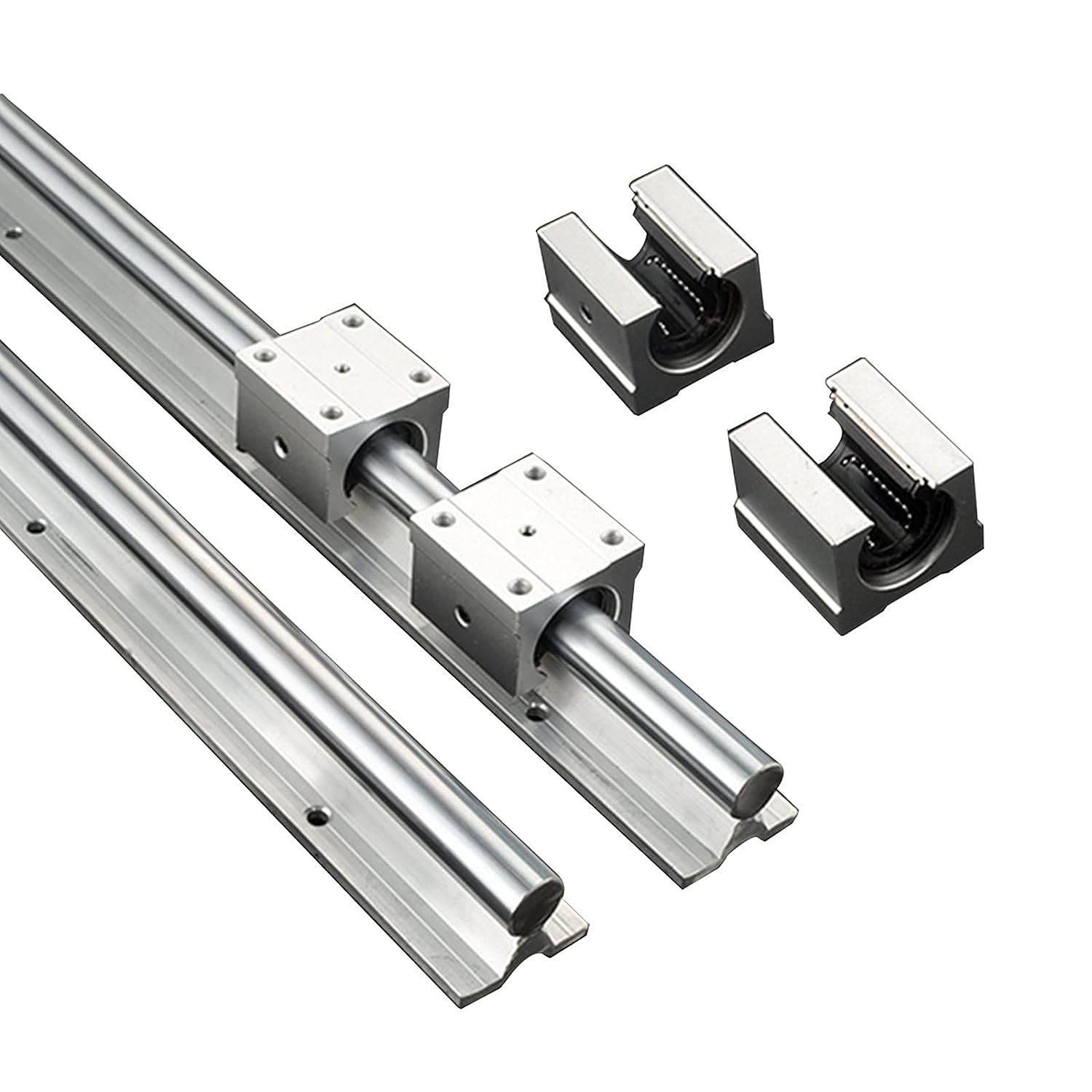

Product Description

| Model | Repeat accuracy | Maximum Liftable Horizontal Weight | Maximum Liftable Verical Weight | maximum speed |

| CFG5 | ±0.01mm | 30KG | 10KG | 1000mm/S |

CF Seiko is a leading manufacturer of linear modules in China, dedicated to advancing industrial automation since our establishment in 2004. We set high standards and deliver top-quality products from our 2 factories in China, covering an area of 9000 square CHINAMFG ., with a team of 150 highly skilled technicians and engineers.

At CF Seiko, we specialize in designing and manufacturing linear modules and have established strong partnerships with over 20 listed companies, including industry giants such as FOXCONN, BYD, GREE, BOE, and more.

Our products offer the same quality as renowned brands like HIWIN, THK, IAI,Misumi and SMC, but at a much more competitive price. We prioritize quality and do not compromise on product standards. We also OEM for these brands.

Our product range includes:

1. Linear Motors

2. Electric Servo Cylinders

3. Ball Screw Linear Modules

4. Belt Driven Linear Modules

5. Rack and Pinion Linear Modules

6. Electric Cylinders Rod Type

7. Cartesian Robots

8. KK Series Module

We are currently seeking distributors in your country. By partnering with us, you can enjoy special discounts, high profits, guaranteed quality, and excellent after-sales service. Our diverse product line is designed to meet all your needs. Join us and explore new opportunities for wealth and success.

If you are interested in becoming a distributor for CF Seiko or would like more information, please do not hesitate to contact us. We are excited about the prospect of collaborating with you to expand our presence in your market.

Thank you for considering CF Seiko as a potential partner.

Warm regards,

Morty Lv(Foreign Trade Director)

ZheJiang Chuang Feng Seiko Machinery co., Ltd.

Add; No.9,PIngdong 1st Road, HangZhou Science and Technology Park, Xihu (West Lake) Dis. District ,HangZhou, ZheJiang , China

FAQ

1. Q: Your products looks nice, can I get a full product catalog with specification for study?

A: Yes, Please tell me,

2. Q: Can you tell me what is your company main business?

A: We mainly design and produce linear modules/actuators/manipulator by ourselves, and provide OEM and export service for overseas clients.

3. Q: Which famous enterprise use your machines?

A: In China domestic, include BYD, Foxconn, LENS Technology and HUAWEI/Apple/OPPO/VIVO etc. supply chain manufacturers are our key account.

4. Q: If so, is it possible get sample machines before trial order?

A: Yes, mail your request details to us we can modify the 3D drawing, prepare 1 or pair of customized sample meet your special needs.

5. Q: Good, how long is your lead-time?

A: 7 working days for sample prepare, 10-15 working days for large quantity order production. (Confirm each bill of international payment need extra 3 working days)

6. Q: Sounds good, how long is the warranty period of your machines?

A: 12-months warranty is provided for our linear modules/actuators/motors, strictly based on sales contract.

7. Q: Wow, I want to do business with your company, what kind of payment terms?

A: Sample order, trial order, repeat order, we accept T/T payment, 30% deposit when signing contract, rest amount pay before shipping. (L/C payment only available for designated countries’ client)

8. Q: What is the best shipment way for your products?

A: For sample machines, the best delivery way is through airplane transport(or land transport), takes 1 week transfer to destination airport, for large quantity goods, the best shipping way is via CHINAMFG ship(or land transport), takes 1 month to destination port, FOB HangZhou, HangZhou, in China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Aluminium |

| Structure: | Dustproof |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there specific considerations for choosing linear rails in applications with varying environmental conditions or precision requirements?

Yes, specific considerations come into play when choosing linear rails for applications with varying environmental conditions or precision requirements. These considerations ensure that the selected linear rail system is well-suited to the specific challenges and demands of the application. Here are key factors to consider:

Environmental Conditions:

- Temperature: In environments with extreme temperatures, the linear rail materials and coatings must withstand thermal expansion or contraction. High-temperature environments may require materials with enhanced heat resistance, while low-temperature settings may demand materials that remain durable and flexible in cold conditions.

- Corrosion Resistance: For applications in corrosive environments, such as those with exposure to moisture or chemicals, choosing corrosion-resistant materials or coatings is crucial. Stainless steel or specialized coatings can protect against corrosion and extend the lifespan of the linear rail.

- Contaminant Resistance: Environments with dust, debris, or other contaminants require linear rails with effective sealing mechanisms. Sealed or covered linear rail systems prevent the ingress of contaminants, preserving the integrity of the system and ensuring reliable performance.

Precision Requirements:

- Accuracy and Repeatability: Applications demanding high precision, such as in CNC machining or optical systems, require linear rails with superior accuracy and repeatability. Choosing rails with tight tolerances, precision-ground surfaces, and advanced manufacturing processes ensures consistent and reliable linear motion.

- Load Capacity: Precision applications may have stringent load requirements. Selecting linear rails with the appropriate load-bearing capacity ensures that the system can handle the specific loads without compromising precision or accuracy.

- Smooth Operation: Precision linear motion often requires smooth and quiet operation. Rails with anti-friction coatings, self-lubricating properties, or advanced bearing technologies contribute to smooth and silent linear movement, meeting the demands of precision applications.

It’s essential to thoroughly evaluate the environmental conditions and precision requirements of the application before selecting linear rails. Collaborating with experienced suppliers or manufacturers can provide valuable insights and assistance in choosing the most suitable linear rail system that meets the specific challenges posed by varying environmental conditions and precision standards.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

Can you provide examples of products or equipment that rely on linear rails for accurate linear motion?

Many products and equipment across various industries rely on linear rails for accurate linear motion. Some examples include:

- CNC Machines: CNC milling machines, lathes, and routers use linear rails to achieve precise and controlled movement of cutting tools, ensuring accurate machining processes.

- Robotic Systems: Industrial robots, collaborative robots, and robotic arms incorporate linear rails for precise and repeatable linear movement in tasks such as assembly, pick-and-place, and material handling.

- 3D Printers: Linear rails are essential components in 3D printers, enabling the precise positioning of print heads and build platforms during the additive manufacturing process.

- Automated Conveyor Systems: Linear rails contribute to the accurate movement of products on conveyor systems in industries such as logistics, manufacturing, and distribution.

- Medical Imaging Equipment: Linear rails are used in medical devices like MRI machines and CT scanners to ensure precise linear movement in the imaging process.

- Aerospace Testing Equipment: Linear rails play a crucial role in aerospace testing equipment, providing accurate linear motion for testing components and systems under various conditions.

- High-Precision Measurement Devices: Instruments used for precision measurements, such as coordinate measuring machines (CMMs), rely on linear rails to achieve accurate and repeatable positioning of measurement probes.

These examples highlight the diverse applications of linear rails across industries where precise linear motion is essential for the functionality and performance of the equipment.

editor by Dream 2024-04-30