Product Description

t slot v slot rail, v-slot linear rail,aluminium profile for assembly line

|

Product Name |

Industrial aluminium profile |

|

Material |

6000series aluminium alloy |

|

Temper |

T3-T8 |

|

Surface treatment |

Mill finish,powder coating, anodizing, wooden grain coating,polishing,eletrophoresis,PVDF, sanding blasting, etc. |

|

Size |

50series |

|

Slot width |

8MM,10MM |

|

Length |

6M |

|

Unit weight |

2.5-7KG/M |

|

Appearance |

Normally square,round and T-shaped,or customized |

|

Color |

Silver,black,blue,wood color,according to clients’ requirements. |

Industrial aluminium profile is apply to frame combination structure,there is a round to transition on the corner,with anodic oxidation surface treatment,elegant,beautiful and resistant to corrosion,it normally connected from inside with specialised bolt and spring fastener.

Name:t slot v slot rail, v-slot linear rail,aluminium profile for assembly line

Item:LE-10-55710

Material:Aluminium alloy 6063

Unit weight:4.6kg/m

MOQ:1kg

1.Industrial aluminium class: Frame construction, Loading platform, closed construction, production line, Civil aluminum frame.

2.Aluminium products: PA molding finishing, surface preparation, aluminium part using for car, motor, elevators, air cylinder and so on. Aluminium products and aluminium profiles using for decorating, advertisement, displaying, lamp house.

3.Stage film and television modeling: Main aluminium frame modeling, screen, predant lamp, audio supportframe,air box and special work table.

1.The raw material is aluminium ingot;

2.Melting:Aluminium ingot melting through a high temperature,and then casting into aluminium bar.

3.Extruding:Open a mould according to the section design,and then press the heated aluminium bar intoaluminium profiles;

4.Anodizing:Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form a layer of oxide film on aluminum products (anode) under the action of applied current. The oxide film has protective, decorative and some other functional properties.We can also do many kinds of other surface treatment.

5.Quality control:Strict standards on quality control to insure your benifits.

1.Machine frames, shelf, door, industrial automation equipment, table for factory and office, storage racks, storage containers, ladders.

2.Convenient construction: Owned modularity, multifunction, You can quickly construct an ideal equipment for garment and no need complex design and processing.

3.Beautiful and practical model: Light and high stiffness, Simple and beautiful appearance without painting.

4.High scalability: Unique design for T type and fillister. There is no need to remove aluminium profiles when installing components but nut and screw can be installed in any position. Refitting equipment is simple and quick.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Color: | Silver,Black,Blue,Customized |

|---|---|

| Temper: | T3-T8, T3-T8 |

| Unit Weight: | 0.5-25kg |

| Material: | 6000series Aluminium Alloy |

| Alloy or Not: | Is Alloy |

| Slot Width: | 6mm,8mm,10mm |

| Customization: |

Available

|

|

|---|

How do linear rails enhance the overall efficiency and accuracy of linear motion in industrial and automation systems?

Linear rails play a crucial role in enhancing the overall efficiency and accuracy of linear motion in industrial and automation systems. Their impact is significant in various aspects:

- 1. Guidance and Stability: Linear rails provide a precise path for the motion of the carriage or moving component. This guidance ensures stability and eliminates deviations, contributing to accurate and controlled linear movement in industrial applications.

- 2. Low Friction: Linear rails are designed with features to minimize friction between the rail and carriage. Low friction contributes to smoother motion, reducing wear on components and enhancing the overall efficiency of the linear motion system.

- 3. High Load Capacity: Linear rails are engineered to support high loads while maintaining structural integrity. This high load capacity is essential for industrial applications where heavy materials or equipment need to be moved with precision and accuracy.

- 4. Rigidity: The rigidity of linear rails prevents deflection or flexing during operation. This rigidity is critical for maintaining accuracy, especially in applications where precise linear motion is required for tasks like machining, assembly, and quality control.

- 5. Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial and automation systems where consistent and precise motion is essential for the success of manufacturing processes.

- 6. Integration of Smart Technologies: Advanced linear rail systems may incorporate smart technologies, such as sensors and feedback systems. These technologies enable real-time monitoring, feedback, and adjustments, further enhancing accuracy and efficiency in automated processes.

- 7. Customization for Specific Applications: Linear rails can be customized for specific industrial or automation needs. Tailoring the rail system to the unique requirements of an application ensures optimal performance and efficiency, whether in a high-speed production line or a precision laboratory setting.

- 8. Long-Term Reliability: The reliability and durability of linear rails contribute to long-term efficiency. A reliable linear motion system minimizes downtime, reduces maintenance requirements, and ensures continuous, accurate operation over an extended lifespan.

Overall, the use of linear rails in industrial and automation systems results in improved efficiency, increased productivity, and enhanced precision. Their role in providing a stable, low-friction guidance system for linear motion makes them integral components in a wide range of applications across diverse industries.

How do linear rails contribute to smooth and precise linear movement in industrial applications?

Linear rails play a crucial role in achieving smooth and precise linear movement in various industrial applications. The key contributions include:

- Guidance: The specially designed profile of linear rails provides guidance for the movement of the carriage along a straight path. This guidance minimizes deviations and ensures that the motion is precise and controlled.

- Reduced Friction: Linear rails are engineered to minimize friction between the rail and the carriage. This low-friction design allows for smooth motion, reducing wear on components and enhancing the overall efficiency of the system.

- High Load Capacity: Linear rails are designed to support high loads while maintaining their structural integrity. This makes them suitable for industrial applications where heavy loads need to be moved with precision, such as in CNC machining or material handling systems.

- Rigidity: Linear rails contribute to the rigidity of the motion system, preventing deflection or flexing during operation. This rigidity is essential for maintaining accuracy, especially in applications where precision is critical, such as in manufacturing processes.

- Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial applications where consistent and precise motion is required for tasks like machining, assembly, and quality control.

Whether used in CNC machines, robotic systems, or material handling equipment, the characteristics of linear rails contribute to the overall performance of industrial applications. Their ability to deliver smooth, precise, and repeatable linear movement makes them integral components in enhancing the efficiency and reliability of industrial machinery and automation systems.

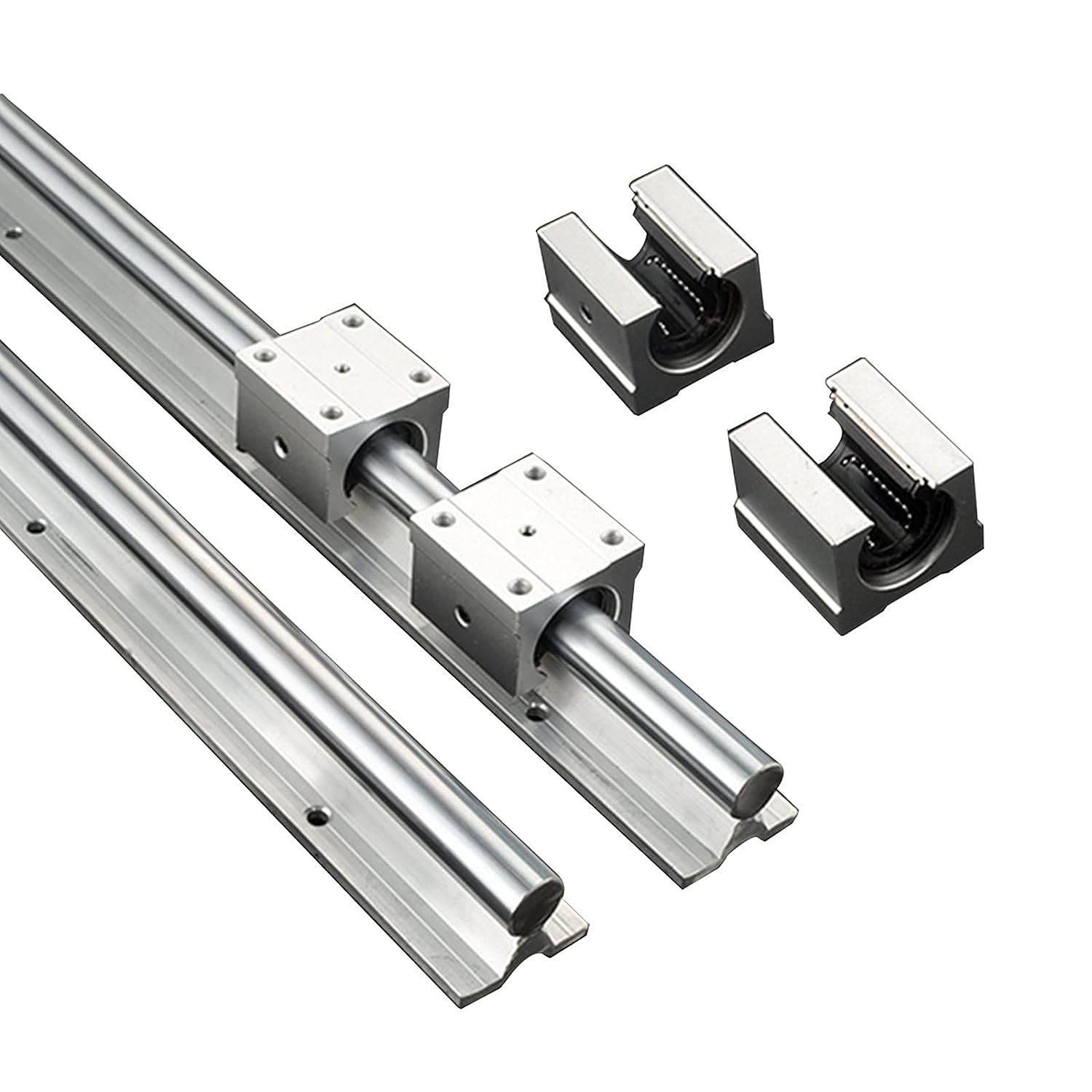

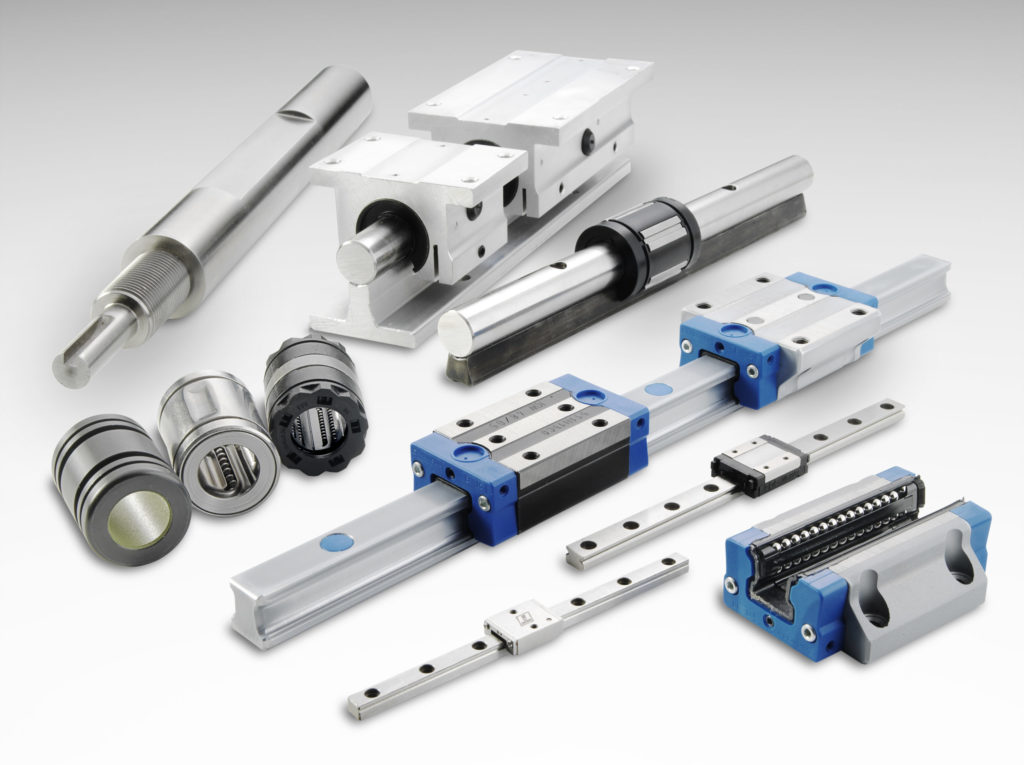

Can you describe the various types of linear rails, such as profiled or round rail systems?

There are several types of linear rails, each with its own design and characteristics. Two common types are profiled rail systems and round rail systems:

Profiled Rail Systems: Profiled rail systems consist of a rigid rail with a specially designed profile, typically featuring recirculating ball or roller bearings. The carriage, mounted on the rail, contains these bearings, providing smooth and precise linear motion. Profiled rail systems are known for their high load capacity, accuracy, and stiffness. They are commonly used in applications where precision and rigidity are critical, such as CNC machines and industrial automation systems.

Round Rail Systems: Round rail systems utilize cylindrical rails and carriages with linear bearings. These systems are often more compact and cost-effective than profiled rail systems. While they may have slightly lower load capacities and precision compared to profiled rail systems, round rail systems are suitable for applications where space is limited, and the requirements for precision are moderate. Round rail systems find use in applications such as packaging machinery, material handling, and some types of 3D printers.

Other types of linear rails include dovetail slides, boxway guides, and more, each with its own design to suit specific applications and requirements. The choice of linear rail type depends on factors such as load capacity, precision, space constraints, and cost considerations in a particular application.

editor by Dream 2024-04-30