Product Description

Product Description

|

Product Name |

MGN Series Linear guide |

|||

|

Material |

Bearing steel, Gcr15, stainless steel, chrome steel |

|||

|

Precision |

P0(ABEC1), P6(ABEC3) , P5(ABEC5) , P4(ABEC7), P2(ABEC9) |

|||

|

Vibration & Noisy |

Z1, Z2, Z3, V1, V2, V3 |

|||

|

Cage |

Brass, Nylon, Steel |

|||

|

Seal / Cover |

ZZ, 2RS, RZ, NR, N |

|||

|

Advantage |

High precision, high speed, long life, high reliability, low noise |

|||

|

Packing |

Plastic bag + wooden box or according to customers’ demands |

|||

|

Quality certificate |

ISO9001-2008 |

|||

|

Function |

Anti-friction, Dustproof, Antirust |

|||

|

Performance |

low friction, low noise, high speed and high precision |

|||

|

Application |

precision part, cnc machining parts, auto parts, industrial parts, etc |

|||

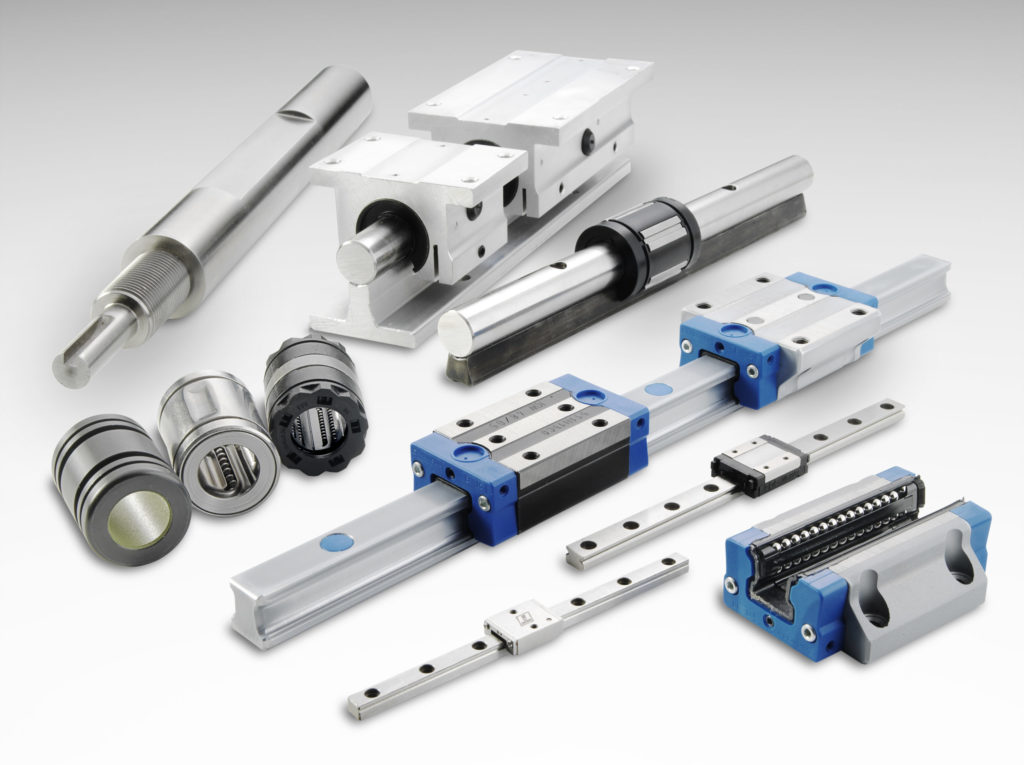

Detailed Photos

Product Parameters

Packaging & Shipping

Company Profile

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is 1 of the biggest linear guide and ball screw manufacture in China,with strong technical strength, advanced production equipments, high-quality staff team and perfect after-sales services, our company is the precision machinery manufacturer with research and development, manufacturing, sales, service all in one.

After Sales Service

Customer Service

The products are mature with high quality. They are not only sold well all over the country, but also exported to Europe, Americas, Southeast Asia, Africa and more than 70 countries. They have excellent marketing performance, highly appreciated and trusted by the vast number of customers.

If you have any needs, Please contact with me directly!

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production. Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters, Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons. We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,and we pack them very well to make sure the goods in well protection.

5. Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,it is really too hard to send all of catalogue and price list for you. Please inform us the style you interested, we can offer the pricelist for your reference.

6. Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear guide supplier since 2011.and we are really factory, you need not pay the profit for middlemen. so we can offer you the lowest and competitive price .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | 3D Printer |

|---|---|

| Material: | Steel |

| Structure: | Rail & Slider |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by Dream 2024-05-02

China Standard China Factory High Quality Cheap Price Linear Bearing Block Linear Guide Rail

Product Description

Our company is a manufacturer specialized in aluminum, the aluminum industry is very professional, and because we are direct selling so also very have the advantage in terms of price, our products are promised specification product delivery in 5 days, we can also open mold customized according to customer requirements, we will according to customer demand for the logistics to find the best the most suitable logistics.

Product Detail

|

Temper |

T3-T8 |

|||

|

Standard |

GB5237-2008 or other International standards |

|||

|

Accessories |

Kingloon or Other supplier appointed by customer |

|||

|

Deep Processing |

CNC / Cutting / Welding / Punching / Checking / Tapping / Drilling / Milling |

|||

|

Fabrication |

Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Welding→ |

|||

|

Surface Treatment |

Powder coating,Fluorocaben coating,Anodizing,Polish,Electrophoresis |

|||

|

QC System |

Inspection before shipment |

|||

|

Payment term |

1. T/T: 30% deposit, the balance will be paid before delivery; |

|||

|

One stop service |

Design-Making mold-Extruding-Machining-Packing-Delivery |

|||

|

Profile type |

1. Window and door profiles; |

|||

ZheJiang COMMON ALUMINUM INDUSTRY PRODUCTS COMPANY is 1 of the leader aluminum industry in Europe,provide first-class services of aluminum industry,design,production ,manufacture and inspection.We introduced Germany High-tech professional technology and make production according to international quality management system ISO9001-2000,passed the international aluminum products quality certification.And acceptance of the customized 6063 aluminum profile and suitable accessories.

RFQ:

Q1: What’s the standard length of your aluminium profiles be shipping?

A: The standard length of aluminium profiles is 6meter, we can cut to specific length as you need.

Q2: What’s your MOQ?

A: We can accept trial orders for prototype, there are plenty of stocks in factory, and can be shipped very fast.

Q3: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10-12 um. Yes, we can do 15um and above.

Q4: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q5: What’s the lead time for small order and mass production?

A: 1~3 working days for small order, and 3~15 working days for mass production of material.

Q6: What certification do you have? What’s your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q7: What’s the packing way?

A: Commonly we use plastic film and kraft paper, also we can make as per customers’ requirements

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Material: | Galavanised Steel |

| Connection: | Male |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the various mounting options and installations for linear rails in different settings?

Linear rails can be mounted in various configurations to suit different settings and applications. The choice of mounting options depends on factors such as space constraints, load requirements, and the desired motion characteristics. Here are some common mounting options and installations:

1. Horizontal Mounting: Linear rails are horizontally mounted when the desired linear motion is along the horizontal axis. This configuration is commonly used in applications such as CNC machines, where the tool needs to move horizontally across the workpiece.

2. Vertical Mounting: Vertical mounting involves installing linear rails to support vertical linear motion. This configuration is prevalent in applications like vertical machining centers, where the spindle moves vertically to perform machining operations on the workpiece.

3. Inverted Mounting: Inverted mounting is where the linear rail is installed upside down. This configuration is suitable when space limitations or specific design requirements dictate the need for the rail to be positioned below the moving component. Inverted mounting is common in some types of robotic systems.

4. Parallel Mounting: Linear rails can be mounted in parallel to support multiple carriages or moving components. This configuration is beneficial in applications where synchronized linear motion is required, such as in certain types of material handling systems or conveyor belts.

5. Cantilever Mounting: Cantilever mounting involves mounting the linear rail with one end extending beyond a support structure. This configuration is used when access to one side of the linear motion is required, such as in loading and unloading stations on manufacturing lines.

6. Tandem Mounting: Tandem mounting involves mounting multiple linear rails in tandem to share the load and provide additional support. This configuration is suitable for applications with heavy loads or long travel distances, ensuring stability and preventing deflection.

7. Floating Mounting: Floating mounting allows for some degree of flexibility in the alignment of the linear rail. This is useful in applications where there may be minor misalignments or variations in the mounting surface.

The choice of mounting option depends on the specific requirements of the application, and engineers must carefully consider factors such as load distribution, accessibility, and alignment to ensure optimal performance and longevity of the linear rail system.

How do linear rails contribute to smooth and precise linear movement in industrial applications?

Linear rails play a crucial role in achieving smooth and precise linear movement in various industrial applications. The key contributions include:

- Guidance: The specially designed profile of linear rails provides guidance for the movement of the carriage along a straight path. This guidance minimizes deviations and ensures that the motion is precise and controlled.

- Reduced Friction: Linear rails are engineered to minimize friction between the rail and the carriage. This low-friction design allows for smooth motion, reducing wear on components and enhancing the overall efficiency of the system.

- High Load Capacity: Linear rails are designed to support high loads while maintaining their structural integrity. This makes them suitable for industrial applications where heavy loads need to be moved with precision, such as in CNC machining or material handling systems.

- Rigidity: Linear rails contribute to the rigidity of the motion system, preventing deflection or flexing during operation. This rigidity is essential for maintaining accuracy, especially in applications where precision is critical, such as in manufacturing processes.

- Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial applications where consistent and precise motion is required for tasks like machining, assembly, and quality control.

Whether used in CNC machines, robotic systems, or material handling equipment, the characteristics of linear rails contribute to the overall performance of industrial applications. Their ability to deliver smooth, precise, and repeatable linear movement makes them integral components in enhancing the efficiency and reliability of industrial machinery and automation systems.

Can you provide examples of products or equipment that rely on linear rails for accurate linear motion?

Many products and equipment across various industries rely on linear rails for accurate linear motion. Some examples include:

- CNC Machines: CNC milling machines, lathes, and routers use linear rails to achieve precise and controlled movement of cutting tools, ensuring accurate machining processes.

- Robotic Systems: Industrial robots, collaborative robots, and robotic arms incorporate linear rails for precise and repeatable linear movement in tasks such as assembly, pick-and-place, and material handling.

- 3D Printers: Linear rails are essential components in 3D printers, enabling the precise positioning of print heads and build platforms during the additive manufacturing process.

- Automated Conveyor Systems: Linear rails contribute to the accurate movement of products on conveyor systems in industries such as logistics, manufacturing, and distribution.

- Medical Imaging Equipment: Linear rails are used in medical devices like MRI machines and CT scanners to ensure precise linear movement in the imaging process.

- Aerospace Testing Equipment: Linear rails play a crucial role in aerospace testing equipment, providing accurate linear motion for testing components and systems under various conditions.

- High-Precision Measurement Devices: Instruments used for precision measurements, such as coordinate measuring machines (CMMs), rely on linear rails to achieve accurate and repeatable positioning of measurement probes.

These examples highlight the diverse applications of linear rails across industries where precise linear motion is essential for the functionality and performance of the equipment.

editor by CX 2024-04-10

China Best price HGH 25 China Factory HGH15 CA Square Linear Guide Slide Block Bearing For HGR 15 actuator CNC Machine Linear Rail drawer slide linear rail

Problem: New

Warranty: 1.5 years

Applicable Industries: Garment Outlets, Manufacturing Plant, Equipment Fix Shops, Foodstuff & Beverage Manufacturing facility, Farms, Retail, Printing Retailers, Building works , Vitality & Mining, Other, Promoting Firm

Excess weight (KG): 4

Video clip outgoing-inspection: Not Available

Machinery Take a look at Report: Not Accessible

Marketing and advertising Sort: New Item 2571

Guarantee of core components: 1 Year

Core Parts: Bearing, Motor

Model Variety: HGH HGW

Materials: chrome metal/GCr15, Chrome Metal Gcr15

Item identify: Linear Motion Xihu (West Lake) Dis.

Packaging Information: sector packing or as your prerequisite

Specification

| item | value |

| Condition | New |

| Warranty | 1.5 many years |

| Applicable Industries | Garment Stores, Manufacturing Plant, Machinery Repair Outlets, Foodstuff & Beverage Manufacturing facility, Farms, Retail, Printing Shops, Construction performs , Vitality & Mining, Push Shaft Bearing Middle Assistance Bearing 381410571 4.85712 5718 Other, Promoting Company |

| Weight (KG) | 4 |

| Video outgoing-inspection | Not Accessible |

| Machinery Test Report | Not Obtainable |

| Marketing Variety | New Solution 2571 |

| Warranty of main components | 1 12 months |

| Core Elements | Bearing, Motor |

| Model Quantity | HGH HGW |

| Place of Origin | China |

| ZheJiang | |

| Brand Identify | YOSO |

| Material | chrome steel/GCr15, Chrome Steel Gcr15 |

| Product name | Linear Movement Xihu (West Lake) Dis. |

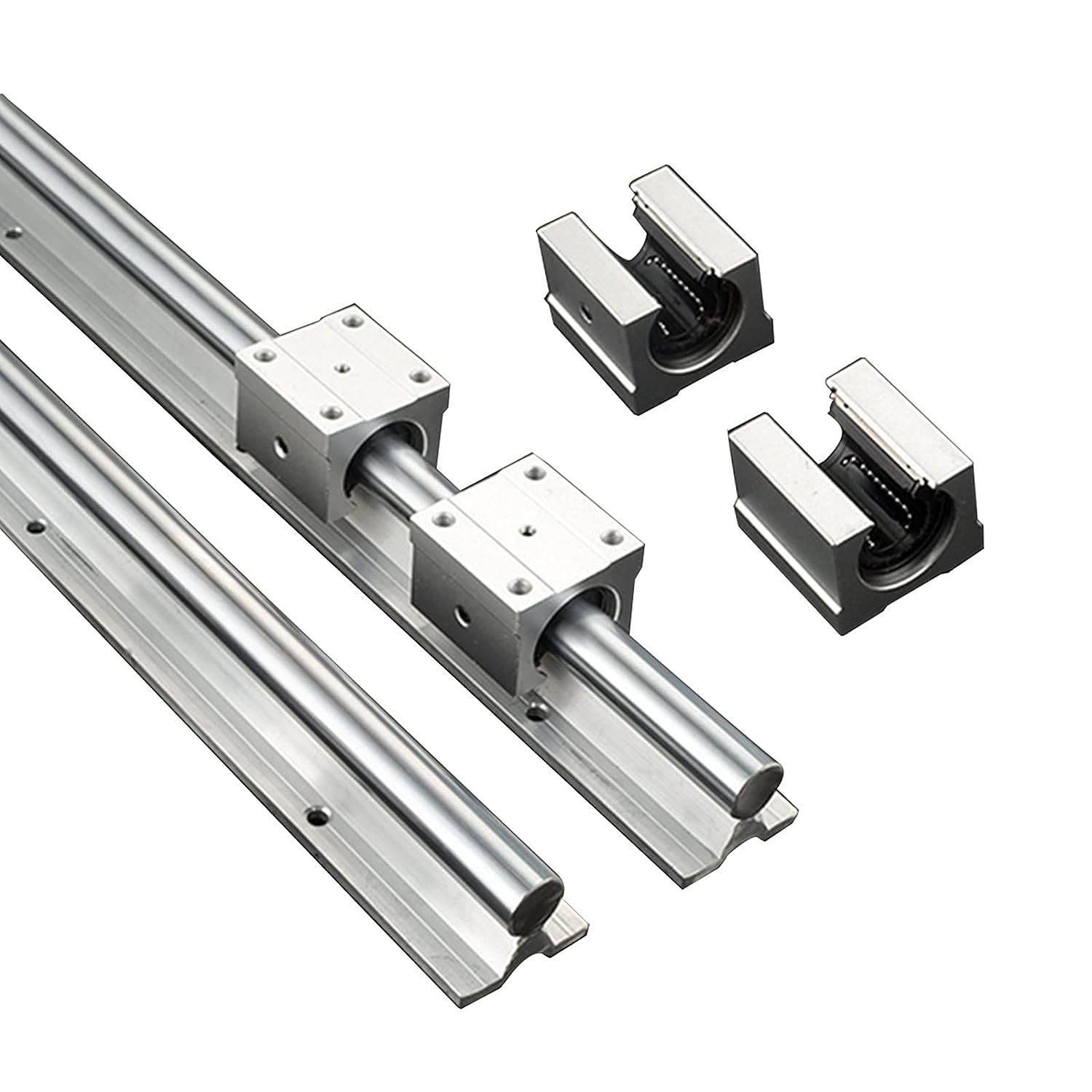

Choosing the Right Type of Linear Rail for Your 3D Printer

Using a linear rail in your 3D printer is a common way to provide support for the bed, but there are some drawbacks to using this type of rail. Learn about the different types of rail and how to select the best one for your project.

Square rail

Choosing the right linear rail can bring significant advantages in cost, durability and performance. Choosing the right rail type is a key step before deciding on the overall design. Choosing the correct type will depend on your application’s requirements. The selection process involves learning from past mistakes and defining the system’s objectives. Choosing the right rail isn’t unlike choosing other components for a machine.

Unlike round rail, square rails require a flat mounting surface. Moreover, square rails can’t span gaps. The rails must be aligned perfectly to achieve the desired parallelism. Square rails also need to be lubricated properly.

Square rails are used for applications that require high load capacity. Square rails are typically used for machine tool applications. They have a greater load capacity than round rails. They can handle heavy loads and moment loads. They provide high precision and accuracy. They also have more surface contact than round rails.

Generally, square rails are more expensive than round rails. Square rails are also more prone to debris. They also need tighter parallelism than round rails. Square rails also need a straight continuous support.

Square rails have higher load capacity and precision. However, they have higher maintenance costs. Square rails also need to be installed carefully. They can be prone to misapplication. Misapplication can happen due to miscalculation or personal bias. Choosing the right rail type isn’t always the right solution for your application. It’s always best to start with preliminary calculations before deciding.

Round rails are generally faster to install. They also allow for greater ranges in rail height. They can also handle imperfect parallelism. However, they also have lower load capacity. They require more parts than square rails.

They can be installed vertically or horizontally. They are also available in different sizes. CZPT provides bearing blocks in different seals. Their bearing blocks can be purchased in long, normal or short block versions. CZPT’s long block versions have a self-lubricating option.

Round rails are more forgiving than square rails. They have less tendency to pull up. They are also less prone to deflection.

CZPT(r) T

Whether you are working in the manufacturing, automotive, pharmaceutical, or food industry, CZPT (r) T linear rail assemblies can be configured for your application. These rail assemblies are manufactured from lightweight aluminum and can be customized to your specifications. They are designed to replace recirculating ball bearings, eliminating messy oil, grease, and downtime. You can download CZPT (r) T linear rail assemblies as CAD files to facilitate customization.

There are two main types of CZPT (r) T linear rails. The T-shaped design is manufactured from hard-anodized aluminum. These linear guides are designed to be lightweight, easy to install, and durable. They are perfect for applications where speed is critical.

For more than 50 years, Sealstrip has been manufacturing packaging solutions with its patented package reclosure device. In its heyday, metal bearings were the standard for package reclosure, but they proved to be expensive and often required frequent maintenance. Fortunately, CZPT (r) T linear guide systems are a better option. They are oil free, corrosion resistant, and come with a number of functional and design features that rival metal bearings.

CZPT (r) T linear rails are easy to install and maintain, so you can focus on the task at hand. Their design is efficient, allowing for the smoothest, most precise motion. CZPT (r) T rail assemblies are also available in stainless steel, making them ideal for applications in harsh environments. These bearings have a unique split adapter that makes installation easy. They are compatible with standard ball bearings. They can carry heavy loads up to 800 pounds.

In addition to CZPT (r) T linear rails, CZPT (r) family of products includes CZPT (r) R linear plain bearings, CZPT (r) S anodized aluminum shafting, and CZPT (r) slide tables. All CZPT (r) products are designed to meet your motion control component needs. They are available from 28,000 stock items. You can also order energy chain systems and chainflex continuous flex cables. These linear guides are designed to help you get the most from your manufacturing equipment. They are the ideal way to replace recirculating ball bearings.

liding contact guides

Generally, linear guides are composed of guide rails, slide bodies and bearing inserts. These systems are widely used in different applications. They are designed to reduce friction, increase power efficiency and increase overall efficiency of units. The guide can be made of steel or aluminum. The slide can be plain surface bearing or a rolling-element bearing. These types of slides have a low frictional resistance, and can be used in high speed applications.

Sliding contact guides on linear rails have sliding contact along the entire length of the rail. The sliding contact is made by a rolling-element bearing, such as a ball, roller or cam roller. Linear bearing slides can be lubricated with grease, oil or vacuum lubricant. The use of linear bearing slides helps to minimize operating temperatures and improves overall efficiency of units.

These guides are used in applications with high precision. They are a good option in applications with limited space requirements. They also provide increased load capacity while reducing the size of the unit.

The present invention provides an alternative to the prior art linear guides. It consists of a linear guide with a replaceable bearing element. This element is removable from the slider without replacing the slide body. It also eliminates the need to replace roller elements in the bearing mechanism.

The sliding contact guides on linear rails are ideal for applications with high accuracy. They are especially useful in high speed applications. They can help grippers pick up objects more accurately. They can also be used for industrial sliding doors. They are also used in a variety of robotics applications.

The sliding contact guides on linear rails can be used in a wide range of applications, from precision machinery to computer numerical control machines. They are available in different sizes and configurations, including the MINISCALE PLUS series. They can be used in vacuum conditions of up to 10-7 mbar. They are ideal for applications requiring high accuracy and reduced power consumption.

They are available in a wide range of sizes, including 7 mm to 15 mm wide. They also have travel distances of up to 42 mm. The dynamic load capacity ranges from 207 to 1109 N. They also offer accelerations of up to 50 m/s.

Drawbacks of “traditional” linear rail in a 3D printer build

Using linear rails in a 3D printer build can increase print quality, but there are also drawbacks. There are some advantages to using linear rails, but you’ll also need to consider the cost and complexity of using them.

A traditional linear rail is a rectangular piece of steel with two dovetails along each side. It’s used to mount the carriage to the printer, and it is designed to provide smoother motion than a linear rod. Despite this, a rail can also be curved, which can create problems when printing.

Another disadvantage is that a single linear rail is more expensive than two linear rods, and it requires a physical frame for mounting. However, it can save you the cost of buying two rods and can also create a unique aesthetic for your 3D printer. Another advantage is that you can anchor the rail for greater rigidity and load-bearing capacity. You’ll also need to make sure that your rails are properly lubricated for a long life. If they aren’t, you’ll likely experience problems with print quality.

The drawbacks of using a linear rail in a 3D printer build aren’t that serious, but they’re still something to consider. If you have the budget, you may want to invest in a more capable printer, rather than in a linear rail. Also, remember that the stiffer your rails are, the less backlash you’ll experience. You’ll also avoid ringing artifacts, which will make your prints look less smooth. Regardless of the type of rail you use, it’s important to make sure that you mount it correctly.

editor by czh 2023-03-18

China Good quality Factory price OEM ODM Double metal bush bushing bearing bush bimetal with Best Sales

Applicable Industries: Equipment Mend Stores

Model Amount: JF800

Sort: sleeve

Materials: Steel+Bronze powder

Normal: DIN1494

Certification: ISO9001:2008

Dimension: Personalized Measurement

Surface area treatment: Copper/ Tin

Packing: Box Packing+Carton+Pallets

Packaging Details: Export regular packing

Port: ZheJiang , HangZhou

Product PARAMETERS Functionality indexJF-800JF-720JF-700JF-20JF930Max Load Capacity150130125710150Dynamic loadTensile Strength185155715710185Oil lubricationMax Sliding Speed51571255Friction coefficient0.06-.140.06-.a hundred and sixty.08-.a hundred and sixty.08-.one hundred sixty.06-.16Oil lubricationMax PV Price Restrict(Grease lubrication)2.82.eighty two.5_.8Max PV Price Restrict(Oil lubrication)257186_ The JF bi-metallic bushings adopts superb gentle steel as the backing, and then the bronze sintered or mock silver pressed at the floor. There are various types of bushings, engine bearings, thrust washers we are giving, and between which bushing is the most generally used sort. The materials most generally adopted for the alloy layer for the bi-metallic bushings is CuPb10Sn10,CuPb24Sn4, CuPb30, CuSn6Zn6Pb3, AISn20Cu and so on. For sake of the environmental security which has drawn much interest internatiosally,our firm developed another type of substance CuSn6.5P0.1 for the alloy layer and it has been widely used in the market place.JF Bimetal bearings are widely utilized in oil lubricating scenarios. Generally beneath minimal pace and oil lubricating situationsassemble with grease and operate with introducing oil periodically, this sort of as suspension, ANKAI a hundred Places Autobus Euro 3 Diesel Manual gearbox ESC Tachogragh Max.Pace 80kmh Algerie steering ball joints, brake pedal points,redirector, connecting rod, slide element of punch. development and earth-relocating products, And so on.Below middle velocity operate with oil,such as connecting rod, shaft and transportation parts of minimize machine. Underneath large pace work within oil, such as equipment box,gas pump,motor,clutch, wind Turbines Hydraulic Swing Generate Gear Motor Yaw Pitch Planetary Gearboxes For Excavator Slew Generate Etc. Product Info CERTICATE Consumer Opinions Hot Market Items Searching&PAYMENT FAQ Q. Are you manufacturer or trade company ?A: We are maker. Q: Can I have a sample get?A: Of course, we welcome sample order to test and verify top quality. Combined samples are acceptable.Q. What is the lead time? A: Sample: 5-7 operating times usually. Mass manufacturing time : thirty working daysQ. Do you have any MOQ limit? A: We never have MOQ, but if amount huge, prices will be lower.Q. What’s your payment term? A: Generally we acknowledge T/T, we also acknowledge L/C, Paypal and Western Union, credit rating card or by means of ALIBABA.Q. Do you offer guarantee for the goods?A: Sure, we supply one particular-12 months promise for the goods.Q. Why do we choose your business? A: Our organization is a professional bearing manufacturer for above twenty several years. We often insist quality very first, and we have advantage inquality control and price. Speak to US

Bushing Software, Sort and Compression Capability

Bushings are cylindrical bushings utilized in machinery. It prevents wear of shifting components and is often utilized as an enclosure. Bushings are also acknowledged as plain bearings or sleeve bearings. You might be pondering what these areas do and how they operate, but this write-up aims to answer all your questions. We are going to go over bushing apps, sorts and compression abilities so you can pick the appropriate 1 for your demands.

software

A bushing is a mechanical part that plays an essential function in numerous various fields. In addition to becoming quite sensible, it assists minimize sound, vibration, use and offers anti-corrosion properties. These properties support mechanical tools in a variety of methods, like producing it easier to keep and decreasing its overall construction. The features of an enclosure depends on its purpose and environment. This write-up will go over some of the most common programs of casing.

For illustration, in an aircraft, the bushing assembly 16 could be utilised for the bulkhead isolator forty . The bushing assembly 16 gives the interfaces and paths essential for recent stream. In this manner, the sleeve assembly supplies a safe, reliable link amongst two objects with diverse electrical fees. They also avoid sparking by escalating the electrical conductivity of the ingredient and lowering its resistivity, thus minimizing the possibility of spark formation.

An additional typical software for bushings is as a support shaft. As opposed to bearings, bushings run by sliding among two relocating surfaces. As a outcome, they minimize friction and managing anxiety, minimizing total maintenance fees. Generally, the bushing is made of brass or bronze. The advantages of bushings are comparable to individuals of bearings. They help prolong the daily life of rotating equipment by lowering frictional vitality loss and use.

In addition to determining progress chances and reducing hazards, the Bushing Anti-Vibration Mounts Market report supplies insights into the dynamics of the business and its important gamers. The report handles world-wide market size, purposes, growth potential customers, problems and regional forecasts. The thorough section on Bushing Anti-Vibration Mounts market provides insights on demand and offer along with competitive investigation at regional and region stage.

type

There are several kinds of bushings. Among them, the SF6 insulating sleeve has the most straightforward structure and is based mostly on composite hollow insulators. It also has several steel shielding cylinders for regulating the electric discipline inside of the enclosure and one more for grounding the metallic protect. In addition to becoming lightweight, this sleeve is also quite tough, but the diameter of its defend electrode is very large, which indicates special set up and dealing with processes are necessary.

Linear bushings are usually pressed into the bore of the shaft and supply help as the shaft moves in/out. Non-push-fit bushings are held in area by snap rings or pins. For specific apps, engineers frequently pick bushings more than bearings and vice versa. That’s why. Beneath are some widespread bushing types. If you need to have to purchase, make positive you know how to inform them aside.

OIP bushings are utilised for oil-filled cable bins, and oil-to-oil bushings are utilized for EHV electrical power transformers. The principal factors of the OIP enclosure are proven in Figure 7a. If you are taking into consideration this kind of bushing for your distinct software, you want to make confident you recognize your specific specifications. You can also consult your regional engineering section for far more data.

All kinds of bushings must be tested for IR and capacitance. The check tap need to be securely attached to the bushing flange. If broken bushings are identified, replace them immediately. Be sure to keep comprehensive data of the enclosure for regimen routine maintenance and any IR screening. Also, be certain to spend focus to tan d and thermal eyesight measurements.

Compressive capability

There are several issues to take into account when picking an enclosure. Initial, the material. There are two principal varieties of bushings: individuals manufactured of crammed Teflon and these made of polyester resin. The former has the maximum compressive energy, whilst the latter has a reduce compressive capability. If you want small amounts, glass-stuffed nylon bushings are the most frequent and very best choice. Glass-stuffed nylon is an inexpensive substance with a compressive strength of 36,000 lbs.

2nd, the substance utilized for the enclosure should be able to withstand the load. For illustration, bronze bushings can lead to steel shavings to slide into the papermaking process. CG components can withstand quite high ranges of dampness, which can harm bushings that demand lubrication. In addition, these components can run for extended durations of time without lubrication. This is notably advantageous in the paper industry, since the casing operates in a humid surroundings.

In addition to the substance and its composition, other attributes of the enclosure should also be considered, like its operating temperature. Although frictional warmth from transferring loads and the temperature of the bushing by itself can have an effect on the performance of the bushing, these aspects decide its provider existence. For high temperature applications, the PV of the enclosure need to be stored low. On the other hand, plastic bushings are usually less heat resistant than steel bushings. In addition, plastic sleeves have a high rate of thermal growth. To steer clear of this, measurement control is also critical.

Low strain bushings have distinct needs. An 800 MVA installation requires a low voltage bushing rated at fourteen 000 A. The palm assembly of the transformer also characteristics a large central copper cylinder for electrical current. The bushing have to endure this sum of current and must sustain an even distribution of recent in the transformer tank. If there is a leak, the bushing must be able to resist the leak so as not to harm the transformer.

value

The price of new handle arm bushings may differ widely. Some parts are less costly than others, and a new part is only $200. Nonetheless, if you change the four management bushings in your automobile, the price can exceed $1,two hundred. The cost breakdown for every area is shown underneath. If you program to exchange all 4, the price of every single bushing may assortment from $200 to $500.

The manage arm bushing bears the brunt of the forces created by the tire and is parallel to the direction of the drive. However, more than time, these elements put on out and want to be replaced. Replacing a single manage arm bushing charges in between $three hundred and $1,two hundred. However, the expense of replacing every single arm bushing relies upon on your car product and driving habits. The control arm bushings need to very last about 100,000 miles before needing substitute.

The fix method for management arm bushings is time consuming and pricey. Also, they might require to get rid of the warmth protect or bracket. In possibly scenario, the method is basic. Stabilizer bar brackets are usually attached with 1 or two mounting bolts. They can also be secured with nuts or threaded holes. All you need is a wrench to get rid of them.

The manage arm bushings are created of two steel cylinders and a thick rubber bushing. These elements can deteriorate from potholes, off-roading or mishaps. Since they are made of rubber, the elements are a lot more pricey than new. Purchasing utilised kinds can preserve you cash simply because you never require to put in them your self. Nevertheless, if you do prepare on fixing a luxurious auto yourself, be confident to locate a single that has a guarantee and warranty.

sustain

To avoid your car from overheating and leaking oil, a correctly working bushing have to be utilised. If the oil degree is also low, you will need to have to check out the mounting bolts to make confident they are appropriately tightened. Verify gasket to guarantee correct compression is used, replace bushing if essential. You should notify your car company if your motor vehicle is immersed in oil. Each time an oil leak takes place, it is really critical to change the oil-stuffed bushing.

Yet another essential element of bushing maintenance is the detection and correction of partial discharges. Partial discharge is brought on by recent coming into the bushing. Partial discharge can lead to tree-like buildings, cracks and carbonization in the discharge channel, which can eventually hurt the casing. Early detection of these procedures is essential to making certain that your vehicle’s bushings are properly maintained. Pinpointing and restoring partial discharges is critical to ensuring optimal procedure, irrespective of the type of pump or motor.

To diagnose casing situation, execute many exams. You can use tan d measurement, which is a strong device for detecting the ingress of h2o and dampness. You can also use energy aspect measurements to detect localized defects and aging outcomes. You can also examine the oil amount by performing an infrared check out. After completing these tests, you will be able to decide if there is ample oil in the casing.

If the oil degree in the transformer is too low, drinking water and air may leak into the transformer. To keep away from this problem, be confident to check out the MOG and transformer oil stages. If the silicone is pink, substitute it. You ought to also examine the function of the oil pump, supporter and handle circuits every year. Check out the bodily issue of the pump and supporter and no matter whether they want to be replaced. Clear the transformer bushing with a soft cotton fabric and examine for cracks.