Product Description

400mm 4040 V Type European Standard Anodized Aluminum Profile Extrusion Linear Rail for 3D Printer and CNC DIY Laser Machine

Product Description

40 series aluminium tubes frame extrusion black silver anodized 0 40160 t-slot aluminium profile

aluminum alloy profile 40×80 aluminium t-slot 40×80 6063 t5 de aluminio extruido perfiles 4080 extrusion

Profile Material: 6063 aluminium alloy T5

Surface treatment: Mill finish, powder coating, anodizing, wooden grain coating, polishing, eletrophoresis, PVDF, sanding blasting, etc.

Best choice for simulator4040/4080/40120/40160 aluminum profile

Slot width: 8MM 6mm or 10mm

Color Natural silver anodised, black, can be customised.

Surface: Mill finish, Anodizeding, Sand Blasting, Powder coating, etc.

Deep processing: Cutting, Drilling, Treading, Bending, etc. Application: Building & Construction, Industry, Machinery, Transportation,

Electrical & Energy, Machinery, Radial profiles for LED cooling, Non-standard Automation, Structure Framing, etc

Certification:ISO9001OEM & ODM

Acceptable Shipping Term : EXW, FOB, C&F or others can be discussed.

| Product Name | 40x40mm Industrial aluminium profile/ aluminum extrusion |

| Profile Material | 6063 aluminium alloy |

| Temper | T5 |

| Surface treatment | Mill finish, powder coating, anodizing, wooden grain coating, polishing, eletrophoresis, PVDF, sanding blasting, etc. |

| The option of Profile | 15/20/30/40/60/80/90/100 series etc. |

| Slot width | 6MM,8MM,10MM |

| Color | Natural silver anodised, can be customised. |

| Surface | Mill finish, Anodizeding, Sand Blasting, Powder coating, etc. |

| Deep processing | Cutting, Drilling, Treading, Bending, etc. |

|

Application |

Building, Industry, Machinery |

|

Certification |

ISO9001 |

|

OEM & ODM |

Acceptable |

Associated accessories connect methods

Industrial aluminium grade 6063 t5 tubing 40120 t slot aluminum extrusion profile 40*120

Easy installations and all kinds of accessories for choose

How to choose the suitable aluminium profile to your design?

Your goal as a designer is to come up with the design that best meets the requirements of the project. We would like to show you

the quick guide with the 4 key points you need to consider when designing with aluminium extrusions.

Understanding these basics will help you identify ways to reduce weight, add functionalities, simplify assembly, and minimize

costs.

1. Designing with the right wall thickness

2. Rounded shapes will improve your design

3. Enhance your products with decoration

4. Achieving cost-efficient production

If you are interested in learning more about using aluminium in your product design, then please contact CHINAMFG and we will put

you in touch with the right expert.

Advantage of Aluminum Extrusion

Langle Aluminum Profile offers over 100 Moulds for aluminum V slot & T slot profile framing systems. The Advantage of using

LE standard aluminum profile are:

1. Saving mould cost and shorten production time;

2. Shorting design and assembling time;

3. Associated accessories are available as well to save your time to resource it;

4. Controlling cost and providing more efficient working project;

5. Improving your systems and space management with our professional technical team.

6.The raw material is aluminium ingot;

7.Melting:Aluminium ingot melting through a high temperature,and then casting into aluminium bar.

8.Extruding:Open a mould according to the section design,and then press the heated aluminium bar intoaluminium profiles;

9.Anodizing:Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form a layer of

oxide film on aluminum products (anode) under the action of applied current. The oxide film has protective, decorative and

some other functional properties.We can also do many kinds of other surface treatment.

10.Quality control:Strict standards on quality control to insure your benifits.

Application

Except the standard profiles, we offers service from tooling design for customized project, extrusion production, assembling,

cutting, drill threading till packaging, give assistance for our customer to develop the new style and functional products.

Welcome for customized Extrusion Aluminum for multiple industrial application, like window & doors, heat sink radio, building

systems, precision tubing, flat extrusion profiles, complex extrusion profiles, Radiator, Assembly line, Frame system, Conveyors,

Workbench, Machine Guards, Stairs & Platforms, Metal Fence, Display rack, Automotive, Motor aluminium housing, Bridge system,

Vessel, Elevator, etc.

1.Machine frames, shelf, door, industrial automation equipment, table for factory and office, storage racks, storage containers, ladders.

2.Convenient construction: Owned modularity, multifunction, You can quickly construct an ideal equipment for garment and no need

complex design and processing.

3.Beautiful and practical model: Light and high stiffness, Simple and beautiful appearance without painting.

4.High scalability: Unique design for T type and fillister. There is no need to remove aluminium profiles when installing components

but nut and screw can be installed in any position. Refitting equipment is simple and quick.

Company Introduction

1. Rich experiences in industrial Aluminium Profile Application for Automation (15 years);

2. Mass available stock for a fast shipping to whole the world;

3. NO MOQ, even 0.5 meter can be acceptable;

4. Supply both aluminium profiles & related accessories to save your time on resourcing;

5. Welcome your CUSTOMIZED design, OEM acceptable;

6. Offer professional services from tooling design, extrusion production, assembling, cutting, drill threading till packaging.

NEVER worry about quality and deadline.

Certificate

Our Promise

1.Offering design and improvement scheme freely.

2.Offering video and photos with details freely during production.

3.Helping customers to do factory inspection freely for his other Chinese suppliers.

4.Producing completely according to the accuracy of drawings,assembly measurement to detect function and strict

quality control to ensure 0 return rate.

5.99% orders can be ensured delivery time.

6.Quote can be offered within 2 days fastest.

7.Delivery time is only 7 days fastest.

8.Responding to the enquiry within 2 hours.

9.Logistics arrangement with high performance to price ratio.

10.The most suitable packing method to different products.

FAQ

Q1: Are you a trading company or factory?

A: we are factory and has over 10 years experience for aluminium profile area.

Q2:What’s normal length of standard aluminum profile?MOQ?

A: The standard length of aluminium profiles is 6571mm, The longest profile that can be sea shipped is 6 meters.

For our existing products, quantity has no restrictions and depends on your need.

Q3: What’s the lead time for small order and mass production?

A: 7-15 working days after getting deposit, and the final lead time will be subject to each individual invoice.

Q4:How can i get a quotation from your company?

A:In order to quote you as soon as possible please provide us the following information as many as you can:

1).Detail drawings (CAD/PDF/DWG/IGES/STEP)

2).Material

3).Quantity

4).Surface treatment

5).Any special packaging or other requirement

Q5:Can I have a sample for testing?

A:yes of course.

For standard profiles we would like to provide our customer samples,but normally 10cm length sample, for

custom profiles,we will provide samples once its moulding finished(generally 10-20 days).

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Window & Door Aluminium Profile, Decoration Aluminium Profile, Heat Sink Aluminium Profile, Glass Wall Aluminium Profile, Transport Aluminium Profile, Industrial Aluminium Profile |

| Shape: | Square |

| Grade: | 6000 Series |

| Temper: | T3-T8 |

| Samples: |

US$ 30/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

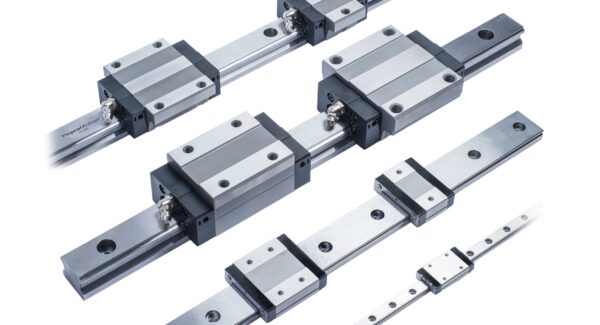

Can you explain the role of linear rails in reducing friction and wear in linear motion applications?

Linear rails play a pivotal role in reducing friction and wear in linear motion applications through several key mechanisms:

- 1. Precision Design: Linear rails are precision-engineered with specific profiles and tolerances. The precise design minimizes contact points between the rail and the carriage, reducing friction and wear to a minimum during linear motion.

- 2. Rolling Contact: Many linear rails utilize rolling contact elements, such as recirculating ball bearings or roller bearings. These elements roll along the profiled surface of the rail, significantly reducing friction compared to sliding contact. Rolling contact also distributes the load evenly, further minimizing wear on specific points.

- 3. Low-Friction Coatings: Some linear rails feature low-friction coatings on their surfaces. These coatings, often made of materials like Teflon or similar compounds, create a smooth and slippery surface, reducing the coefficient of friction. This results in smoother linear motion and less wear on the rail and carriage components.

- 4. Lubrication: Proper lubrication is essential for reducing friction and wear in linear motion systems. Lubricants applied to the rolling elements or the rail surface create a thin film that separates the moving parts, minimizing direct contact and friction. Regular lubrication intervals are crucial for maintaining optimal performance and extending the lifespan of the linear rail system.

- 5. Sealing Mechanisms: Linear rails often incorporate sealing mechanisms to protect against contaminants. Dust, debris, and moisture can contribute to increased friction and wear. Effective sealing prevents the ingress of contaminants, preserving the integrity of the rail and reducing wear on critical components.

- 6. Material Selection: The choice of materials for both the rail and carriage components influences friction and wear. High-quality materials with good wear resistance, such as hardened steel or specialized alloys, contribute to the long-term durability of the linear rail system.

- 7. Regular Maintenance: Implementing a regular maintenance schedule is crucial for reducing friction and wear. Inspections, cleaning, and lubrication ensure that the linear rail system operates smoothly and efficiently. Identifying and addressing any signs of wear early can prevent more significant issues and extend the overall lifespan of the system.

By incorporating these design features and maintenance practices, linear rails effectively minimize friction and wear in linear motion applications. This not only enhances the efficiency and accuracy of the system but also contributes to the long-term reliability and durability of the linear rail.

What are the typical load capacities and travel distances for linear rails?

The load capacities and travel distances for linear rails vary based on the specific design, size, and application requirements. Here are general considerations:

Load Capacities:

- Light-Duty Applications: Linear rails in smaller sizes may be suitable for light-duty applications with load capacities ranging from a few hundred pounds to a few thousand pounds. These are commonly used in applications like 3D printers and light-duty automation systems.

- Medium-Duty Applications: Linear rails in medium sizes are designed for applications with moderate load requirements. Typical load capacities for medium-duty linear rails range from a few thousand pounds to tens of thousands of pounds. These are often used in CNC machines, robotic systems, and material handling equipment.

- Heavy-Duty Applications: Larger linear rails are built for heavy-duty applications with substantial load requirements. Load capacities for heavy-duty linear rails can extend into the hundreds of thousands of pounds. These are employed in industrial machinery, aerospace testing equipment, and other heavy-duty applications.

Travel Distances:

- Short-Range Travel: Some linear rails are designed for short-range travel, with typical distances ranging from a few inches to a few feet. These are suitable for applications with limited linear motion requirements, such as in certain types of printing machinery.

- Medium-Range Travel: Linear rails for medium-range travel cover distances from a few feet to several feet. These are commonly used in applications like CNC machines and automation systems where moderate linear motion is required.

- Long-Range Travel: Linear rails with long-range travel capabilities are designed for applications where extensive linear motion is necessary. These can cover distances ranging from several feet to meters and are used in applications such as large-scale industrial automation and material handling systems.

It’s essential to consult manufacturer specifications and consider factors such as speed, acceleration, and environmental conditions when selecting linear rails to ensure they meet the specific load and travel requirements of a given application.

What industries and machinery commonly use linear rails for precise linear movement?

Linear rails find widespread use in various industries and machinery where precise linear movement is crucial. Some common applications include:

- Manufacturing Machinery: Linear rails are integral components in CNC machines, milling machines, lathes, and other manufacturing equipment. They ensure accurate and repeatable motion for precise machining processes.

- Robotics: Linear rails play a key role in robotic systems, providing the necessary guidance and precision for the movement of robot arms and other robotic components.

- Automation Systems: Industries employing automated systems, such as conveyor systems and pick-and-place machines, often utilize linear rails to achieve precise linear movement in the automation process.

- 3D Printing: Linear rails contribute to the accuracy and stability of 3D printers by facilitating the precise movement of print heads and build platforms.

- Medical Devices: Linear rails are used in medical equipment such as imaging devices, diagnostic instruments, and robotic-assisted surgery systems, where precise linear motion is critical.

- Aerospace: The aerospace industry employs linear rails in various applications, including aircraft manufacturing and testing equipment, to ensure precision in movement and positioning.

- Semiconductor Manufacturing: Linear rails are used in semiconductor manufacturing equipment for precise movement in processes such as wafer handling and inspection.

These examples demonstrate the versatility of linear rails across different industries, highlighting their importance in applications that demand accurate and reliable linear motion.

editor by CX 2024-04-10