Product Description

Product Description

HDPE Plastic Linear Chain guide Rail wear strips Wear Strips for Conveyor Belt

UHMWPE guides, also known as polyethylene slides, are processed from UHMWPE, a thermoplastic engineering plastic with an average molecular weight of more than 9 million. This material has a number of positive effects on the performance of the grinding environment.

The properties of UHMWPE ensure that this plastic material is very light, very strong, self-lubricating, and has excellent sliding properties, which ensure quiet, smooth operation and long term functional reliability in factory manufacturing.

Moreover, UHMWPE guide rail has high impact resistance, good corrosion resistance, very stable chemical properties, and can withstand corrosion of various corrosive media and organic solvents within a certain range of temperature and humidity.

Polyethylene guide rail has high adhesion resistance, the guide rail surface is not easy to CHINAMFG to other materials, and it is non-toxic and tasteless, is the United States food and Drug Administration and the United States Department of Agriculture permit in the food and pharmaceutical field application of materials.

Detailed Photos

Product Parameters

Ultra-high molecular weight polyethylene guide rail of the most common shape of T and U, but also can produce type C, L, CF and CK, CT and so on each kind of specification, can be completely in accordance with the drawings processing, can choose size and thickness, long service life and self lubricating maintenance free, factory direct sales, strictly control the quality, deeply the general customers the high praise, welcome to inquire order processing.

APPLICATION

UHMW Plastic Chain Xihu (West Lake) Dis.s Application Scenarios:

Industrial manufacturing, elevator pulleys, corrosion-resistant and wear-resistant mechanical parts, star wheel, transmission bottle screw, etc.

About Us

ZheJiang OKAY Plastic Industry Co., Ltd. is located in the northeast of the intersection of Tengfeng Avenue and 107 National Road, Yigou Town, Xihu (West Lake) Dis. County, HangZhou City, ZheJiang Province, the new material entrepreneurship park, covering an area of more than 8,000 square meters.

We are an industrial and trade integrated import and export trading company, the company has been operating for more than 20 years, trained a number of excellent R & D team, committed to providing customers with high quality products and services, so far, our products have been exported to the Americas, Europe, Asia and other regions.

The company always adhere to the “unity, efficiency, hard work, innovation” business philosophy, market-oriented, service as the purpose, enthusiasm to provide customers with high quality products, user demand is our pursuit. ZheJiang OKAY Plastic Industrysincerely welcome friends from all walks of life to visit, guidance and business negotiations.

FAQ

1.Q: What are the terms of payment?

A: 30% down payment, 70% balance. The payment method is flexible, T/T, LETTER of credit, Alibaba online and other payment methods are accepted, 30% advance payment, 70% balance payment, can be openly discussed.

2.Q: May I take samples?

A: Yes, we can provide samples to you free of charge, but you have to bear the freight.

3.Q: Can you customize irregular shapes?

A: Of course. “Innovation” is 1 of our business philosophy. We warmly welcome customers to open up new markets for us.

4.Q: How about your after-sales service?

A: We have A dedicated after sales tracker, any need can contact us at any time. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | UHMWPE |

| Structure: | Tyre Crane |

| Installation: | All-Terrain Crane |

| Driven Type: | Hydraulic |

| Carrying Capacity: | Special Weight Level |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

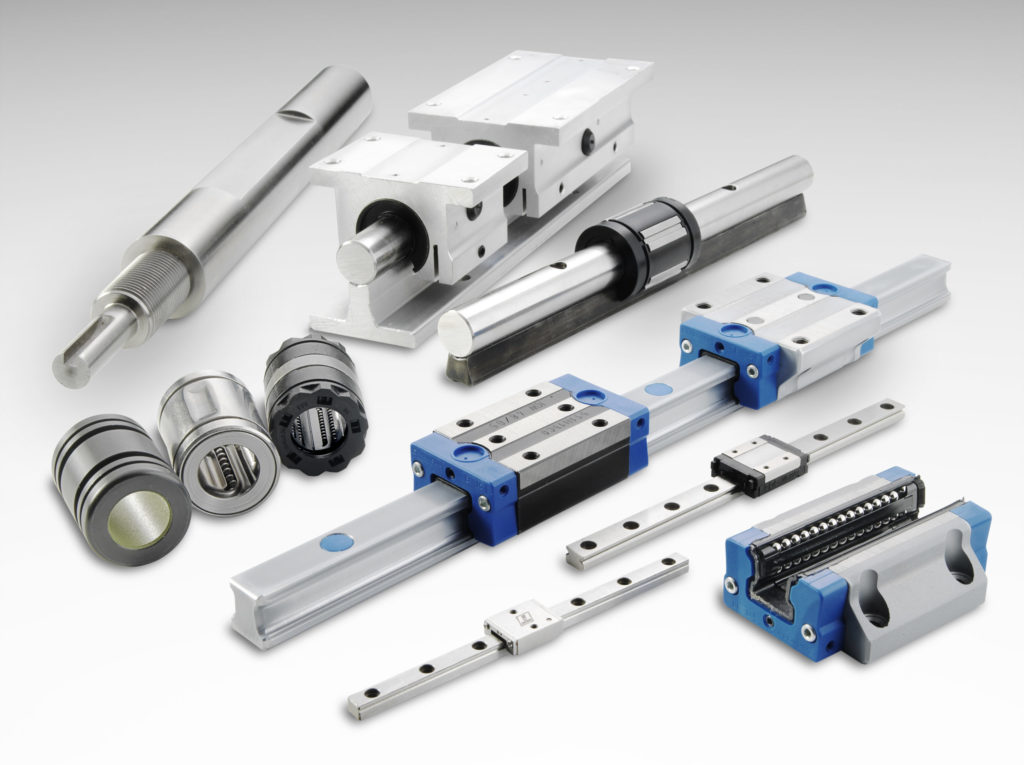

How do linear rails enhance the overall efficiency and accuracy of linear motion in industrial and automation systems?

Linear rails play a crucial role in enhancing the overall efficiency and accuracy of linear motion in industrial and automation systems. Their impact is significant in various aspects:

- 1. Guidance and Stability: Linear rails provide a precise path for the motion of the carriage or moving component. This guidance ensures stability and eliminates deviations, contributing to accurate and controlled linear movement in industrial applications.

- 2. Low Friction: Linear rails are designed with features to minimize friction between the rail and carriage. Low friction contributes to smoother motion, reducing wear on components and enhancing the overall efficiency of the linear motion system.

- 3. High Load Capacity: Linear rails are engineered to support high loads while maintaining structural integrity. This high load capacity is essential for industrial applications where heavy materials or equipment need to be moved with precision and accuracy.

- 4. Rigidity: The rigidity of linear rails prevents deflection or flexing during operation. This rigidity is critical for maintaining accuracy, especially in applications where precise linear motion is required for tasks like machining, assembly, and quality control.

- 5. Accuracy and Repeatability: The combination of guidance, low friction, and rigidity ensures that linear rails provide accurate and repeatable linear movement. This is vital in industrial and automation systems where consistent and precise motion is essential for the success of manufacturing processes.

- 6. Integration of Smart Technologies: Advanced linear rail systems may incorporate smart technologies, such as sensors and feedback systems. These technologies enable real-time monitoring, feedback, and adjustments, further enhancing accuracy and efficiency in automated processes.

- 7. Customization for Specific Applications: Linear rails can be customized for specific industrial or automation needs. Tailoring the rail system to the unique requirements of an application ensures optimal performance and efficiency, whether in a high-speed production line or a precision laboratory setting.

- 8. Long-Term Reliability: The reliability and durability of linear rails contribute to long-term efficiency. A reliable linear motion system minimizes downtime, reduces maintenance requirements, and ensures continuous, accurate operation over an extended lifespan.

Overall, the use of linear rails in industrial and automation systems results in improved efficiency, increased productivity, and enhanced precision. Their role in providing a stable, low-friction guidance system for linear motion makes them integral components in a wide range of applications across diverse industries.

What are the typical load capacities and travel distances for linear rails?

The load capacities and travel distances for linear rails vary based on the specific design, size, and application requirements. Here are general considerations:

Load Capacities:

- Light-Duty Applications: Linear rails in smaller sizes may be suitable for light-duty applications with load capacities ranging from a few hundred pounds to a few thousand pounds. These are commonly used in applications like 3D printers and light-duty automation systems.

- Medium-Duty Applications: Linear rails in medium sizes are designed for applications with moderate load requirements. Typical load capacities for medium-duty linear rails range from a few thousand pounds to tens of thousands of pounds. These are often used in CNC machines, robotic systems, and material handling equipment.

- Heavy-Duty Applications: Larger linear rails are built for heavy-duty applications with substantial load requirements. Load capacities for heavy-duty linear rails can extend into the hundreds of thousands of pounds. These are employed in industrial machinery, aerospace testing equipment, and other heavy-duty applications.

Travel Distances:

- Short-Range Travel: Some linear rails are designed for short-range travel, with typical distances ranging from a few inches to a few feet. These are suitable for applications with limited linear motion requirements, such as in certain types of printing machinery.

- Medium-Range Travel: Linear rails for medium-range travel cover distances from a few feet to several feet. These are commonly used in applications like CNC machines and automation systems where moderate linear motion is required.

- Long-Range Travel: Linear rails with long-range travel capabilities are designed for applications where extensive linear motion is necessary. These can cover distances ranging from several feet to meters and are used in applications such as large-scale industrial automation and material handling systems.

It’s essential to consult manufacturer specifications and consider factors such as speed, acceleration, and environmental conditions when selecting linear rails to ensure they meet the specific load and travel requirements of a given application.

How do linear rails differ from other linear motion components like linear guides or bearings?

While linear rails, linear guides, and bearings are all components used in linear motion systems, they differ in their design, functions, and applications:

Linear Rails: Linear rails typically consist of a long, rigid rail and a carriage that moves along the rail. The rail has a specially designed profile to provide guidance, and the carriage supports and carries the load. Linear rails are known for their ability to handle high loads, offer precise linear motion, and reduce friction for smooth movement.

Linear Guides: Linear guides encompass a broader category that includes linear rails. Linear guides refer to any mechanism that guides linear motion. Linear rails are a specific type of linear guide with a distinctive profile. Linear guides, in a general sense, can include other mechanisms like dovetail slides, boxway guides, and more, each with its own design and application.

Bearings: Bearings are components that reduce friction between moving parts and support radial or axial loads. While linear rails may incorporate bearings within their design, bearings, in a broader sense, can be standalone components used to support rotating or linear motion. Linear bearings, for example, specifically support linear motion and may be used independently or as part of a linear rail system.

In summary, linear rails are a specific type of linear guide with a defined rail and carriage design, whereas linear guides encompass a broader category. Bearings, on the other hand, are components that reduce friction and support loads, and linear bearings specifically cater to linear motion.

editor by Dream 2024-04-25